Tumbling FDM Metal Prints for Shine

HTML-код

- Опубликовано: 3 окт 2024

- In this week's episode I will be showing how you can use a rotary tumbler + various tumbling media and a little elbow grease to achieve a nice shine on ColorFabb BronzeFill and CopperFill as well as Proto-Pasta Stainless and Magnetic Iron. Special thanks to Heather Blaikie of heatherblaikie.... for graciously lending me the files for this video.

The tumbler, not shown, was a Thumblers Tumbler AR-12. While this is pretty expensive the continuous operation capability and large capacity makes it a good buy. Preferably choose a mixed bag of ceramic tumbling media so that you can get into all the corners of your model without difficulty. Same applies with the stainless media, although use what you can find and fits your budget. Both media's can be easily sourced through Ebay and/or Amazon.com

Condensed instructions:

3D print part in metalic filament of your choice. Try and print at a low layer height so you end up with a smoother model.

Sand any rough spots away and remove any globs as the material tends to ooze a lot.

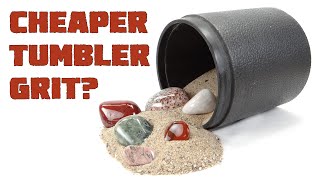

Toss into your tumbler with some ceramic media and enough water to cover the media + a little more. The water helps lubricate and clean the parts. If you plan on tumbling more than 24 hours, stop at the 24 hour mark and rinse the media off and replace with fresh water. Repeat every 24 hours as needed.

Once done tumbling in ceramic media switch to stainless media. I find the less water you have the better. 1/2 - 1 cup of water tends to be perfect. Also if you can use distilled water as it will help prevent water spots if you have hard water.

When done tumbling thoroughly dry the parts off with a clean rag and rub with favorite polishing compound. I prefer Mothers Mag Polish and NuFinish.

Avoid tumbling dissimilar metals in the same drum at the same time as tarnishing can occur. Make sure to rinse media well between materials so that particles from one media don't inadvertently show up in another. I have had it happen and it maybe not a desired result!

Follow me on social media at:

Twitter: / cwcrawlers

Instagram: / crazywhitemachinist

Get stuff 3D printed by me at: www.3dhubs.com...

![BabyChiefDoit - Too Slow (feat. STAR BANDZ) [Official Music Video]](http://i.ytimg.com/vi/zayaxws7RPg/mqdefault.jpg)

It's funny how much effort actually goes into polishing these metal particle filaments, I've done a few polished prints (sans tumbler!) and it literally takes hours of work! I'll have to go find the Australian analogues to those polishing products :P

+Maker's Muse It does! Unless its a simple FLAT shape... it takes forever. They always seem to forget that. Really any kind of paste polish works and the NuFinish is a special "non wax" sealer for your car. Mothers Products is HUGE over here in the states.... so being that it gave me better results than Brasso I stuck with it! Plain and simple!

You should try heat/laser polishing - works pretty well for some geometries