Это видео недоступно.

Сожалеем об этом.

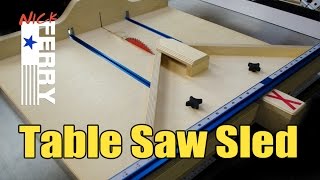

Cross-Cut Sled for Contractor Table Saw

HTML-код

- Опубликовано: 7 апр 2021

- This is a smaller cross cut sled designed to use with a contractor type table saw. A crosscut sled can increase safety and accuracy when using your table saw. This table saw sled has hold down clamps and a fence stop for safer, repeatable cuts. It also has a detachable extension fence. With a single miter slot bar, you can also move the sled over and use a dado stack off the edge without ruining your sled.

Cross Cut Sled Plans: www.etsy.com/l...

Website: www.woodpackdi...

Instagram: / woodpackdiy

Bob Barker's Instagram: / bobbarkers_world

Reference Video:

William Ng, 5 cuts to a "perfect" cross-cut sled: • 5 Cuts to a "Perfect" ...

5-cut calculator:

windridgewoodc...

Affiliate links for tools, I make a small commission on qualifying purchases at no extra cost to you.

Tools:

DEWALT 10-Inch Table Saw (DWE7491RS): amzn.to/3z4vcDU

Freud 8" Super Dado Stack: amzn.to/2TJXN1j

Freud Diablo 10" 50 tooth ATB blade: amzn.to/3pnPCDz

DEWALT 20V MAX XR Cordless Router (DCW600B): amzn.to/3fTc2te

Dewalt 20V Max Cordless Drill/combo: amzn.to/2Rqy50V

Dewalt Palm Sander, 1/4 sheet: amzn.to/3ikKa2U

Kreg K4 Pocket hole jig: amzn.to/2SfW4QN

24-piece router bit set for ¼ in shank: amzn.to/2RqJpdz

Tape Measure: amzn.to/2SdP0nJ

Mechanical Pencil: amzn.to/3uT8mfh

Dust Deputy Delux: amzn.to/2T23eYU

Wood Glue Dispenser: amzn.to/3ppyZYa

Safety Ear Muffs: amzn.to/3cnvqMG

Grr-Ripper 3D Push Block: amzn.to/2S4nBVz

Feeler gauge: amzn.to/3ih4It2

Digital caliper measuring tool: amzn.to/3gaglPK

Forstner bit set: amzn.to/3wZyVRA

Supplies:

T-track hold down clamps: amzn.to/3wVOsBR

T-track 48 inch: amzn.to/3yY68yq

ZEROPLAY Miter Bars: amzn.to/3wZYL7X

3-Inch Fence Flip Stop: amzn.to/3wXyK9g

4-point stud knobs, 5 pk: amzn.to/3z70aLS

¼-20 Threaded inserts: amzn.to/2TO10gt

#woodworking #Crosscutsled #DIY #tablesaw #tablesawsled #woodworkingplans #buildplans #SketchUp #Etsy

Build plans available here: www.etsy.com/listing/983589910/cross-cut-sled-plans?ref=shop_home_active_3

I also forgot to mention in the video that you can use this sled with the dado stack by moving the miter slot bar over to the other miter slot as well. Let me know your thoughts on the build!

Anthony, I see that you install a safety block at the rear of the sled to protect your hand from the blade at the end of the cut. Why Not but a STOP on the bottom of the sled to prevent the possibility of the sled to travel far enough for the blade to come thru the rear ??

So nice to see diy work with average tools. Thank you for sharing. As a newbie to woodworking this was so easily understood and easy to follow.

Glad you enjoyed it!

WELL DONE

Thanks!

Love the use of Bob in your videos. Dogs always make videos better!

Thanks! and yeah, I think they make everything better!

Love the helper…can’t do without them!

Very nice! I appreciate your integrity and craftsmanship. Incorporating a couple of your design ideas. (Routing round edges and thread inserts) As a matter of fact, I have the front and back fence glued and clamped to my level as I speak! Subscribed!

Awesome, thank you!

Nice work, Anthony, and it's always great to see the shop helpers. Great use of the extension and T-tracks. Thanks for the calculator link, as well. It's fun to see it making the rounds through the various builds. You earned a new subscriber.

Thank you!

If you make the safety Block protrude down below the sled it would act as a safety block and a physical stop for the sled.

The main reason that wouldn't work (if I'm understanding the idea correctly) is that the stop would prevent the sled from going far enough forward to complete most cuts.

Yes

Cannot help but notice at 4:15, the level clamped to the board as a router guide is moving significantly. Did it not affect the router cut?

I cant remember now for sure, but you are probable right. I think i didn't clamp down well enough and ended up having to redo the bottom piece. so that is probably the footage from it.

Very nice. I have a helper like yours only she's a cat but just as helpful and demanding. :))

You need to make a detailed 20 minute long minimum video on how to make a tennis ball holder!

Haha, I agree!

@@woodpackdiy I use a small dowel held on with a thumb tac at the end of the string as the guide for the car to stop in the garage. It's not as obtrusive as the tennis ball but does the job perfectly. It's been in place for over 20 years.

Using a dowel somehow sounds more appropriate for a workshop too!

New sub to your channel here. Really like your no hype style. Not sure if its because im Australian but most US wood work channels are way over the top and short on good visual info. 10/10!

Do you have an Amazon link for the sliders you used by chance?please.

P.s. I'd be interested to know what measurements you'd get now it's done with the extension arm and screws in place etc using that 5 cut method. It must change your square a very slight touch.

Thank you! Glad you like the channel. I think this is the one you were askign about. ZEROPLAY Miter Bars: amzn.to/3wZYL7X

That's a good point, it probably does change the square some. But to be honest, whenever I do use the extension, I typically am just trying to get the piece to a more manageable size. It may be a good idea to keep the piece slightly long and then do the final cut without it to be safe.

the best

Anyway, we can get the dimensions as I have a work cited saw as well

How does Bob react when you start saws or make noise in the shop? Does he run away or did he get used to the loud noises or do you keep him out if the shop when doing that sort of thing?

He has never reacted much to loud noises (even with things like fireworks or thunder). He just ignores it and goes about his business. What he really doesn't like is if I go too long without paying attention to him! But I do send him inside if im going to be doing a lot of table saw work just to minimize the impact on his ears long term.

Would this work with a DeWalt table saw with a 8.25 inch blade or do you need a saw with a 10 inch blade?

This should work well with the smaller blade/saw

..nice sled, I will be copying!

How come your table saw can take a dado set, I thought the arbor is too short for that, I have the dw745. Did you modify it or is the arbor just longer on your saw compared to the dw745, thanks

Yeah, the arbor on the DWE7491RS is longer (I assume). That's one of the reasons I got it. The arbor can hold up to a 3/4" dado stack.

Real safe useing grinder for people that don't know any better wow you have to remember some people follow you guys on here and don't know better then to use bad news practice. Good video otherwise 👌

I WAS THINKING CHEAP VASECTOMY.

Subscribing for the dog

It's pretty, but super simple as far as sleds go. Add some standard angles to the mix and you'd be on top. Just sayin.

Is the table saw the 8 1/4” one?

It's a 10" saw. DWE7491RS

Oh, I recently got the 8 1/4. I plan on building your table to house mine when my shop is built. Really enjoy the videos. Keep it up! 👍🏻👍🏻

Why do you have a mirror in your wood shop ?

It was there when we moved in. After a while I got used to it and just never bothered to take it down or put anything else back up. So, basically, laziness. lol

@@woodpackdiy thanks for the reply. I also wondered about the tennis ball hanging from the string. BTW it was a good video , I have not subscribed yet I'll watch some other videos and decide then . And your dog Bob Barker is awesome I wish I had thought of that name.

The tennis ball is just a marker for parking. And Bob Barker says thanks!

Just to make sure to looking good in his content while pulling off such projects. :-)

Nice sled. Just wondering if the T track could be to low if the blade is extended to max. And did you used just one rail from the saw or did I missed something?

@@petezahut9545 at max height, the blade still doesn't come close to the t-track. And yes, I only used one rail. That way I can move the sled over to the left and make cuts off the edge. This is useful for angled cuts and also have done some with a dado stack this way - without ruining my zero clearance for regular cuts.

I was outa here in 10 seconds due to RUclips ads. Sorry.

YOU TUBE does not have a logical set up. I just watched this video and there were no YT ads.. Other videos do have ads. They did show a prompt at the beginning if I wanted to subscribe to YT for ad free videos. Of course I said no.

I have the DW 744 contractor saw and it's been a great saw for building trellises, cat houses, and general carpentry where absolute precision isn't required. However, if you need table saw-level precision and true square, this is not the saw to ever use! Reasons being is that the aluminum fence is way off from one end to the other - mine had 0.090 (90 thousandths or the equivalent of 9 standard sheets of paper) on my dial indicator which is about as useless as it can be for precision cuts - although it looks straight and lines up with the miter slot. The second problem is that the parallelism between the blade and the table can only be adjusted so far and it goes out of adjustment quickly. So anything that is cut on this type of saw will inherently be out square through those combination of inherent errors. All things being equal though, for it's intended purpose as a jobsite saw, it's been a great saw over many decades.

Precision isn't required for woodworking, because if you wanted precision you wouldn't' be using wood. Wood is a living thing unless kept in a vacuum. For what most YT woodworkers want is good enough for the job at hand, as you said.

@@williambranham6249 You obviously don't build fine furniture that requires extremely tight joints that must last for decades without coming apart. And please don't tell that to my customers who pay 2-5K for an artistic wooden heirloom-quality jewelry box that has to last for generations and where each corner joint must be as tight 50 years from now as they are today! True, wood moves and breathes over time but the artistry of making something out of wood that will last for generations is both understanding grain direction and minimizing wood movement in the piece so that the joinery remains tight season after season and it doesn't break itself apart!