How to Install WRB House Sheathing (ForceField)

HTML-код

- Опубликовано: 9 май 2019

- Grace and Corbett show the latest development on their home build- the wall sheathing, which is also the air tightness layer and weather barrier. It's called ForceField, and here you'll see a demo of why it's such an important component in the system, and how to install it for a higher performance home.

More on ForceField at: ForceField.BuildGP.com

More on this build at: HomeDiagnosis.tv/atlanta-homes...  Наука

Наука

Love you guys...Being very meticulous about my works, and seeing someone else who is as well doing a tutorial that is very concise (STRAIGHT TO THE POINT, WITHOUT THE UNNECESSARY JIBERESH) truly makes watching this video enjoyable....A+ job..

Thanks Zach

Corbett, you have done a excellent job of explaining this part of the project.

Thanks, Dave!

I love this series!

X4 in the liquid flashing. Nice to see more sheeting products. with that coating like zip systems.

I think liquid flashing would have been a better choice then the tape in that location.

Great information!

Favorite humorous moments:

11:27 seeing Corbett imagine southern living @180F.

12:52 “use your little brushy”

Thank you for laughing with us D

Just wanted to share the way I do this, I know your not concerned with speed, but what if it was faster and better? I sheathe the walls on the floor, this allows you to tape while on the ground, much easier and you can get a better tape joint. No moving ladders around for the tape or humping sheets of osb up ladders. Add the sheathing around the rim joist after. Since you at ground level and the pieces are small this process goes very quickly. Use a sealant behind the bottom course of sheathing to mudsill, if you seal your mud sill to the foundation before hand this gives an extremely tight connection. We consistently blow below .5 ach50 with this method. Not trying to be a know it all, just trying to share some knowledge.

Gee is that anything like measure down so you have the overlap of the bottom sill and bottom plate? OMG that might be easy . Doing a bit of liquid flash while the panels are on the ground might also make things a bit easier to achieve lower air door scores also

Have you ever raised a 16’ 2x6 wall with 12” of extra OSB at the bottom? Can’t imagine not breaking all the bottoms off and feeling like an ass.

@@HomePerformance start at 4:25 ruclips.net/video/RA3X7YJKMBQ/видео.html

@@HomePerformance it's called wall jacks

@@HomePerformanceyou use wall jacks and you toe nail a few 8s through the bottom plate to the sub floor- this keeps them from sliding and acts as a hinge as you stand them so the don’t slide. You liquid flash the rim right before standing. It’s how we do it on a production basis

What do you thing about using this product vs Zip for walls in California!? What would be your preference?

I just heard you say "three feet of eaves." Interesting to me, as I have decided to build nothing less than 24 inches on my projects. It requires a lot of thought on trim and supports but it keeps the walls and windows more dry!

Hell yeah man. My structural engineers are trying to spec something that will work, but we’ll do 2 ft min. We’re tacking the eaves on after the enclosure is perfect.

@@HomePerformance I think they tack on 12 inch eaves, but how can you make sure anything more than that is OK to tack on? I think what Matt Risinger is doing is still using rafters, but sealing with Zip sausage tubes. He has a great video on youtube called "Zip 2.0" I think.

@@fordguyfordguy structural engineer just gave me calcs and a detail that will work with tacking on 2' eaves. I wouldn't feel comfortable without the calcs.

Home Performance looking forward to seeing it!

@@HomePerformance

My guess is the structural screws tying the overhangs back into the framing gave just enough hold to deal with a 24" overhang, as long as half the OSB was over the structural framing of the house too.

24" at 40 PSF shouldn't be any problem for a couple lag screws per stud at 16" OC

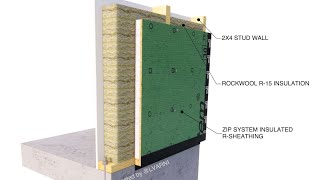

Just a cheaper version of zip, but in your case is best choice for the dollar. No need in wasting more on the better tape. I used zip and liquid flash but I used 2 layers of felt paper and bricked my house. Only did 30” overhangs. Did 100% rock wool in 2x6 walls

Wouldnt you want to install the sheathing horizontally for better shear and racking strength. Then you could stagger them every 4'. Vertically you could only stagger them 2' max if you are working on 24" centers. Less if you are on 16's.

Since the shear strength is largely dependent on the pullout value of the nails, it's more dependent on the nailing schedule rather than the orientation of the OSB.

Vertical orientation and a tight nailing pattern, 4-6" O.C say, means easier taping of the seams too.

Question, did you look into fluid-applied flashing?

Makes the rim joists/foundation sealing easy.

It can also make dealing with over-driven fasteners simpler.

I'd likely have done the tape at the base of the wall different.

Wrap it around the bottom instead of leaving the gap.

Now you have a gap that can expand/contract, and as the tape degrades over time, it could crack, venting the entire gap around the base of the wall to the outside.

Yes, we’re aware of liquid applied, but we chose this approach for our particular home.

@@HomePerformance yes you did. the real question is why since you are aware of the other positives of those added methods

There is no single best answer in life. Beware silver bullets.

@@HomePerformance heck I could see that LOL was curious why one method over the other.

Stay tuned and you’ll get the whole picture :)

Just wondering why you chose forcefield over zip system? Looking forward to your video on that dimple membrane on foundation.

The two systems do essentially the same thing, and Rick Jordan is ALSO one of the inventors of ZIP. ForceField is his improvement on several characteristics of the performance and install, eg taping ease and vapor perm. They actually test the perm of the whole product after the membrane is applied, which not everyone does. Also, I found the people at the company to be a lot more fun and communicative.

@@HomePerformance I read the patent lawsuit Huber filed against GP for Forcefield and in it they claimed Forcefield was an inferior product due to the tendency of the membrane coming loose off the board. I have no idea if that's true or not, but GP ended up paying licensing fees to Huber over this. As a guy looking for a sheathing for my house, I'm just trying to figure out which is better. Forcefield is cheaper, but is it better than Zip? There's no real videos or info I can find that makes this direct comparison.

I imagine part of a lawsuit settlement like that might be to not compare the products, so they can’t do it. Ultimately, they do exactly the same job within a wall system like ours, so if you’re protecting them, they’re interchangeable

Great video! Thanks!

With pleasure, Alex

I'm not sure I've heard you discuss why Forcefield sheathing was better than, say, OSB with a peel & stick membrane, like Vycor Env-s or Henry Blueskin VP100 or equivalent. Is the sticking agent a contaminant and IAQ issue, or was it more cost?

Time is the main saver imho. All-in-one wrb sheathing is just more streamlined to install in some cases.

@@HomePerformance

Like, say, when you're 16 feet in the air hanging onto a ladder? 😉

It must have been a sight seeing you try to manhandle those sheets that high up. They're not the heaviest things by pure weight, but the square footage that weight is distributed across makes them so awkward.

Glad to see someone takes all the youtube safety warnings (commenters) seriously with those hard hatts

After 4 years how is the forcefield osb holding up ?? Just curious causr im thing going towards forcefield vs zip system . Zip sustem is soaked and this is glued on sort of. Curious how it holds up

No complaints, no failures

Looks great 👍🏻!... when’s HVAC going in?

Dude, I got a hilarious bid for $40k, no materials included. I will be working on that myself in a few months. Want to come help? Bryan’s coming to party too!

Yeah man!

Get your butt down here my friend

@@HomePerformance yes but I dont know where you are so can only get there via you tube

There are other advantages to your installation method. It is extremely difficult to keep the bottom plate perfectly flat, and sheeting while the wall is laying flat more often than not results in larger than optimal gaps at best, or a giant rocking horse and more future setting and interior cracking at worse. One won’t make as much money installing sheathing your way, but unquestionably it will make a significantly stronger, better sealed structure.

Thanks, AF-O6

We're did you buy those panel and how much per panel

Lumberyard. I believe they were $30/sheet

can you use that tape on zip sheathing?

Good q- NO, you can’t, because ZIP is adhered to the rough side of the OSB, so their tape is much thicker to fill all the crevices, and must be rolled hard.

what is the price of it?

Aren’t the paper collated nails at a different angle and require a different nail gun?

There are many different types in all angles

very interesting stuff, good job. Take it easy on the parents though!

if its an old house this is pretty impossible right?

Anything is possible if you have unlimited funds and time, but working within constraints would probably mean you'd have to make compromises.

Why wouldnt u put the flashing before the plywood then plywood and tape again just an extra step that makes the house bug water and wind proof

As always, there’s more than one way to do it

This is more a video for people who are having their homes built for them with a generous budget. Using this to double check the $ they are spending is justified. I would do everything done in this video if my project materials were donated by the companies. I love "I use galvanized nails the whole way cause I dont wanna switch them out of the nail gun" .....all of that adds up for a non-sponsored self-funded project using a home equity loan. I'm not frugal, I'm just paying for it all and doing all the work myself. Hey, informative though.

Sure, Sean, I hear what you’re saying. FYI, even though we are very fortunate to be able to ask for product from our favorite companies in exchange for making videos of their install here, we’re spending hundreds of thousands of dollars on this house, not including land. You spend money on what’s important to you- so Grace and I spend it here. We don’t drink or buy video games, I cut my own hair for the past 20 years. Decisions, decisions. Also, not everyone has parents who can and will help you build a house, so another amazing fortunate happenstance there too.

Inventor? Aren't they licensing this product from Zip or had to discontinue it due to a lawsuit? Honestly just curious...

No, the same guys actually invented both systems. There was apparently a lawsuit because ZIP wanted to keep the inventors from making competition. But they settled and as long as they keep manufacturing the way they do, then the products are different enough legally, I guess.

OMG, saw ForceField sheathing at Home Depot, this video was amazing and closed the deal for me on their competition - Zip Sheathing system. This was the worst commercial for this product. Sad it was the first one in the search engine results.

Umm ok man

What is the Georgia Pacific warranty terms and conditions on their ForceField System? Previous GP product experience says to ask now and compare with like systems like ZIP etc. See: forcefield.buildgp.com/DocumentViewer.aspx?elementid=16043 and forcefield.buildgp.com/DocumentViewer.aspx?elementid=16042 and forcefield.buildgp.com/DocumentViewer.aspx?elementid=16041 with more details at forcefield.buildgp.com/forcefield-resources.html

Check out the ZIP System with Matt Risinger at ruclips.net/video/CVAzMmgijGk/видео.html FYI the ZIP system is widely used in wet climates... it really works!

10 year, but it’s transferable, unlike ZIP. Ultimately, if it’s installed correctly as part of a tuned system, you shouldn’t need anybody’s warranty.

@@HomePerformance The GP documents takes a lawyer to understand... lol Thanks!

@@HomePerformance A few more videos on siding... Hurricane Testing - Whats the Failure Point? ruclips.net/video/mSFV0gvVxRk/видео.html

14:01 Since when is 50 years the life of a building. That means most of the houses I’ve lived in are past their life? That doesn’t make sense.

Insane- having to pull out te plastic fro nails, and then Han nailing them all in over again ?

"they're designed to last 50 years or more" (ruclips.net/video/u20-UEwy_a8/видео.html)

Why not tape the nails?

Extra work, time, and material- payoff is minimal if you have your gun set correctly. However, we did tape the nails if you continue to the rain screen video.

@@HomePerformance awesome thanks. Do you remember how much each board cost when you bought them? I’m finding them for $33/board.

The price has gone up for all lumber products. They were around $22 at the time I believe.

@@HomePerformance yea I’m building a house it’s insane.

It’ll go back down once you’re done haha

Hot dipped galvanized cannot go in modern pressure treated wood. Should use stainless!!!! believe this - galvanized will corrode very fast in PT wood.

Mmm, I'm pretty sure any HT Galv fasteners specifically are tested with PT lumber, and say so on the packaging

@@HomePerformance This is actually a well known problem, with much written about it. But don't take my word for it - Tons of information out there on this:www.deckmagazine.com/design-construction/fighting-fastener-corrosion_o; www.ggashi.com/wordpress/wp-content/uploads/PT-Lumber-Causes-Steel-Corrosion.pdf

@@fordguyfordguy At least that first article you mention specifically says to use hot-dip galvanized fasteners- NOT electro-plate galvanized ones, which will disintegrate.

Why in the world are you using a stick gun instead of coil? Why didn't you use a gasket under the bottom plate?

Why in the world would we use a coil gun? Why in the world put a gasket under the bottom plate?

@@HomePerformance Coil gun would be less reloading since you would have 250+ nails in the gun instead of 56 with the stick gun, save some time. Gasket under the bottom plate is good backup for air sealing and sometimes bug intrusion.

Skin is an organ? 🤔

As a matter of fact

The whole building science thing is out of control.

Haha

hat under hardhat? lol

There is no way a real builer would vote he time to hand nail in all those thousands nails flush

If the customer is paying him for a high performance build they should. And it doesnt take that long really. You have to go back and tape the seam. Run through it with a hammer, that's a minute per seam. Then tape it and smooth it out. That's another 3-5 minutes per seam. I'd say a full 8 hour day to do the who0e house