My Electrolysis De-rusting System

HTML-код

- Опубликовано: 22 дек 2024

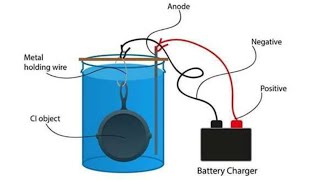

- This is not a how-to for making an electrolysis de-rusting tank - there are plenty of videos posted by others if that is what you are looking for. This is simply a video of the system that I came up with for you to check out and perhaps get inspiration from. Enjoy!

![BLACK BAG - Official Trailer [HD] - Only in Theaters March 14](http://i.ytimg.com/vi/Du0Xp8WX_7I/mqdefault.jpg)

Thank you for the inspiration. Today I built my unit. I took your idea of using the conduit splices, used the ground wire from romex, doubled it and twisted it to make a 5 gallon bucket / 5 rebar / manual battery charger unit to clean the rusty axe heads I have. So far so good, I was able to find the foundry mark. Love this no cost version using things I had.

I love the design. The top ring to hold the rods is one of those "why didnt I think of that" designs. now I need to mimic yours. Great job.

Looks like lots of places to cause a short…

One of the best if not THE best presentations I have seen on the subject. I spent 30 years in engineering, and this is typical of the way stuff should be designed. Simple direct to the point and well executed, no beating around the bush. Like Larry says, "Git 'er done!" You have done an excellent job and an excellent presentation with out all the technical jargon bullshit. You are a BORN engineer.

What a kind thing to say! :)

That's a great setup there! I'll be sure to keep this in mind, going forward. I built a temporary 4'x5' "tank" for electrolysis rust removal from steel wire shelving. Using thick plastic visqueen, draped over a simple 2"x8" boards lying flat on the concrete floor, which was outside, but covered. It worked great at removing rust from 3 dozen steel shelves, and then it was easy to disassemble when finished.

Great video Albert..! I really like the design of your tank. I've been doing some research,and I would like to make some suggestions.

1. The higher the amperage, the quicker it de -rusts the item. 2. 14 gauge wire doesn't cut it. Get heavier leed wire. 3. The rebar anodes work, however, 2" x 20" graphite plates, wouldn't corrode,they would give more of a charge surface, so, you wouldn't need to replace them, and clean them. You could use graphite rods, also. They are costly, but the results are well worth it. 4. A chemist friend of mine suggested using sodium sulfate, instead of sodium carbonate. It may work better as an electrolyte.

Are you referring to the wires (14 gauge?) coming directly from the dc power source?

What ratio of sodium sulfate would you use in your solution? Do you need a lot?

This is really great. I just built my first tank w/6 anodes and a 10-gallon plastic storage bin today, and it's working great. But I LOVE how modular and stable your setup seems. I'll definitely be utilizing many of your ideas in my next effort. Thanks for the great post.

Best setup I've seen and I've researched electrolysis for quite some time.

Your's is the best electrolysis set-up I have seen. Now, I have to go back to the drawing board.

This is the nicest E- tank setup anyone has ever made. Incredible design. Well done.

So nice to see someone really go all in and make a true rust remover machine. What you did was something I was actually stinking about doing this for a while. Keep up the great work. Show's me great mind's think alike Albert. Keep up the great work too.

Kudos, sir. I’ve only just started learning about such set ups, through starting my first motorcycle renovation, but your set up here is next level from what I have designed. Thanks for the ideas.

Albert... LOL my grandpa's name, you really have one of the best , practical ability to do small items and larger items to be de-rusted. IF one was to actually see the 30 gallon barrel next to the big rubber made tub

the 30 gallon takes much less space.. much smaller space. as its vertical, all things are variable and as you have the cross sections which you can hang individual items,,, this, that can be scaled in any tub or barrel situation..but your system is economical and includes many many size large and small without going all in for a giant tub or barrel for those of us who don't have that much space to occasionally de-rust something....besides an engine block ...great video mant thanks

This my friend is the cats ass! Thanks for the great video and explanation. I have been doing electrolysis for a few years and this will make my life much easier. I think I will out drain spout and tap on the bottom. Top shelf and all the best. I do use the power supply also but have used the battery charger as well. I use wood blocks for isolation of parts as well.

This has some fantastic design elements that I’ll be incorporating into my own E-Tank, thank you!

This is the ultimate set up! It looks so professional. I am going to put one of these together just like it.

Best design on all of youtube..

Only thing that could make it a little better is a barrier between the rebar and the center of the tank so you would never have to worry about contact with the rebar and creating an arc...

could you drop the rebar in pvc pipe so water will still flow around but remove the accidental touching of the parts being cleaning from the sacrifice?

The same tank used to remove the iron oxide should be able to replace it with a protective coat of something else simply by changing polarity and the rods/electrolyte. I Think :) We dont need a good finish, just one that wont oxidize or vaporize under the heat(zinc-easy). Excellent build btw. Thanks for the run through.

regarding the conduit couplers - maybe a bit of grease filled in there would avoid corrosion? or maybe if you're welding adjacent, braze the rebar to the copper?

I like your design and there was the one guy that said it was over engineered. There was the original Volkswagen Beetle then there was the Porsche turbo Carrera!I tried this a few weeks ago but all I had was a 5 gallon bucket. Substituted muratic acid as my electrolyte and used a variac for my power supply. First piece was done using 12vdc and took 6 hours - not stellar. Second piece was with 32vdc and left overnight. Amazing results! Plan on building bigger and better and using higher voltage for next trials.

Isnt it higher ampage you'd want for faster results?

DevynGuevara: YES. I don't know the limits because my high voltage Variac is hooked up to something else now and I haven't done anything else with it since. I'll let you know

Scott Burrous alright. My set up used to be a 5 gal bucket and a 2amp ac to dc xbox 360 power brick/inverter. Now i just used a car battery carger that has 10 amps and a fancy trash can i made

I tried half a cup o Ferric Chloride in my temporary setup and it worked rather well. Was your HCl diluted or neat?

GlenislaGhilli

I would love to see other things you build. You seem pretty darn smart.

Outstanding setup & info. I bought the same barrel a week prior to seeing this video. I'm definitely going to "Appropriate" your design! 😂 Thanks & GOD Bless!

Very nice build. It will last as long as the rebar is still hanging. That should be the only thing that will eventually require replacing. Kudos!

Very nice set up. great info.

I Play around with etching the surface on axe heads and i will definitely use this set up but on a small scale. Great vid. Thanks

Nice rig. I currently use a 20 amp battery charger and large rectangular tank but I think I need to both increase the number of anodes and get a supply like yours.

Excellent craftsmanship!!!

Pretty cool design. I was wondering if you ran a grinder around the outside of that rebar before you put it in to remove that slag coating. Once I did that, mine worked twice as well

I do like the looks of your set up.

I'm trying to get different ideas, and yours is a great one. The way you have the rebar mounted and the brace to hold the parts is really a cool idea. May I suggest for that parts hanger, if you choose to connect all 5 together, use 2 pieces of flat bar drilled to match the holes already made for hanging parts, cris-crossed on the wooden "X".

What I'm wanting to remove rust from is a pair of "wings" off an old '80s Craftsman 311.... model table saw. As I do like the way your electrodes are done, I will have to go with something more flat for the liquid tank.

Thanks for the great video!

Arlie

Nice video! I like the EMT set-screw couplers to re-bar mechanics for your sacrificial's, great idea! I'd like to suggest a better electrical method for attaching the copper wire though, drill and tap the ends of the re-bar then connect the copper wire with small bolts.

ingenious set up! Love it! BUT....just a suggestion....you might want to consider replacing the leads FROM your DC power source with heavier gauge cable and alligator clips...other than that, your setup really looks great! 👍👍👊👊

nice job good thought . stainless wire clamps last a long time .thanks for sharing i will update my tank

You can get pre cut 2 foot lengths of rebar at home depot or lowes.

Anodes need to have a lot of surface area, when they get a build up on them they become less efficient. I did the same with threaded rod and found out that using metal sheets welded to the rods improved the performance. Bravo for using heavy duty wire, but from what I can see in your setup is the leads may be a 22 gauge wire and will never hold any type of high amperage.

Well engineered. I made a similar tank using rebar as the anodes. I drilled a hole in one end and tapped it for 1/4" threaded rod about 2" long. Then I made a daisy chain of wire that connected to each of the 4 rebar using electrical eye crimp connectors and some 12 gauge wire. Put the eyelet over the threaded rod and screw down a wingnut on each rod for a solid connection. I also epoxied four 1" pieces of 3/4" PVC pipe in the bottom of the barrel, spaced equidistant around the inner circumference. They hold the rebar in place. So where did you get that red ring of plastic at the top?

Can you tell me what the brand name of the charger you used and model number? I liked everything except for 5he reber I want to 7se flat stock. I think it maybe a faster way to remove the slugs. Please help me out. Ii have a 33 gal blue barrel I may look for a 33 barrel though. Thank you very much sir

Very tidy, very neat.

Only thing I would change is using an insulated heavy guage wire instead of bare copper to integrate the positive connection field of re-bar, and maybe wrap the conduit connectors with a water resistant or compatible electric or duct tape. That might reduce the possibility of arcing or sparking given the flammable gas by-products generated from the electrolysis process. Might be a small thing probability wise, but everything I have read cautions against risking DIY electrolysis set-ups to any kind of exposure to sparks or flame, especially when used indoors.

Why not just use a steel oil barrel and thus increase current density and efficiency? I use this method and put a 12V 21W car bulb in series to prevent shorts damaging the PSU.

Also, use copper pipe for cathode connection, soldering wires to it with crocs on the end. saves all the wingnuts and bolts and wood etc.

Nice design, clean and neat. Think I'll give it a try but have the cross piece rest on the top of the lip for better support of heavier metal; all those holes thru the red rim worry me.

Please describe more the power adapter you bought

What’s the Best way to get the black coating off after the process?

Nice. Do you think that method would work for removing the color from stainless steel welds? Nice setup. I might make a large dip tank myself

Shouldn't the area of the anode be twice as big as the are a the cathode? Is the rebar surface of the rebar big enough?

You didn't mention what you set your DC power supply on to perform the Electrolysis.

As high as it can go.... Looks to me a more powerful DC source would be the way to go. I personally use an old 14A 24V battery charger for electrolysis derusting. The more power the faster.

Nice video and very informative. How did you manufacture the red ring ? Or where did it come from ?

it is the screw on lid that came with the barrel i just cut out the center, is all.

I forgot to mention the cost of this thing and that is about $135 total.

The DC power supply off of eBay for about $40.

The plastic Barrel on eBay for about $50.

10 - 2' lengths of 1/2" rebar including cutting fee for about $9.

10 - pipe conduit connectors from the local hardware store for $8.

8' - 6 gauge bare copper ground wire for about $10.

Some old heavy duty speaker wire I had laying about - free.

A collection of clips I got for less than $10 on eBay.

5 - hanger bolts from the local hardware store for about $10.

Any suggestions now on a power supply? amperage, etc...

What is the name for those type of clips you got on Ebay? I've tried several word combos now. Can't find that kind, yet. Please help.

Excellent job and great video. Thanks!

Could you tell me the brand of the power supply you are using?

I like your design, it will def get the job done.

Did he say that manifold was subjected to electrolysis for OVER a week? That sounds expensive. And very slow. Any thoughts on this?

That's a great idea! Have you ever thought about putting some kind of weakly acidic acid the barrel? Maybe like vinegar?

Im not sure how electrolysis would affect the acetic acid :searched' (CH3COOH) byproduct -ethane and carbon dioxide', but vinegar by itself works amazingly well- without the pitting you can get with elec.

Vinegar aka acetic acid is only weakly ionized in water. Almost all the electrolysis set ups for cast iron (like skillets) use sodium carbonate. Vinegar doesn't readily carry much current like a salt solution.

Where dif you get the red ring? It looks like the lid screws into the Red ring, is that so?

Good setup. I would avoid using galvanized metal anywhere such as those conduit clamps--not great for your health if you can find an alternative.

Did you use anti-oxidation grease on you rebar/copper wire connections? What about a bottom drain spigot/petcock?

You certainly could but rebar and wire are cheap or free. A bottom drain would be more work but could be convenient on larger electrolysis tanks. Industrial platers (plating and electrolysis work similarly) have drains on their tanks. Use plastic of course.

I have green chunks show up in my tank while cleaning cast iron, Ideads on why?

Water is dirty

I like your set up!

What voltage and amperage have you found to work best?

Awww, I love that kitty cat :)

Nice setup. Definitely a good idea to use a proper power supply rather than a battery charger.

It looks fancy but it doesn't matter if you have got one or 100 rebars, it ends up the same quality with the same speed. The speed depends on the Ampers. The higher the Amper the electrones will travel faster so you would take shorter time.

That's a nice set up

When you get through with removing the rust from your project. You need to plan to remove the rust from the rebar before your next project. It will go faster.

May I ask what brand the DC power supply is you've got? Regards

Any chance you can share a link the power source? Maybe?

do you have a drain on that barrel

What did you find to be the best voltage and amperage settings?

I maxed it out on my power supply at 12V which is pretty much the same as a standard over the counter car battery charger you can get from Walmart. Obviously more amperage will do more but you don't want to cook the system. I would say that going 12V @10 -amps will work the best.

So what Voltage and what amp seem to work the best

That cat's like, "fuck it. I don't want to live. De-rust ME."

Will it de-rust steel ?

No just wood

I would remove rebar to clean off rust evry day or two to increase efficiency…or make a second rack to just pop in

Very nice design..

you should up your game and nickel plate your copper clamps so they never corrode. nickel is great for conductivity and corrosion resistance. and its done through basically the same process.

bro charge is negative of positive ?

I think i would take and put PVC pipe with hole drill in it around the rebar. To make sure your part and the rebar don't touch

That'd probably cut efficiency down quite a bit.

Very elegant

nice setup

I really like you design, but the way I've found with DC power, those tiny leads don't carry the voltage well. doesn't look like they could carry the amps to put power to all that rebar. I mean have you ever tried to jump start a car? I run mine with 10 gauge. You couldn't even use those small leads to warm a cigarette lighter in a car. How many amps does that thing put out? Just saying, it would probably work much better with a battery charger and bigger leads.

Yeah his set up is dumb I got a basic ass bucket and a battery charger that can do 10-50 amps. I only use 1 anode and get better results then his in 2 hours. Also cost me $0

Very impressive

convert your pool to derust a car

Edward LOL!

old bathtub is an option too!

overkill?

I like the links of that.

Hard wire is better, the electrolyte will eat those clips off especially when plating with stronger acids.

For a tank that big I would think a drain valve would be a good idea.

But hydrogen currupt metall structure, especially hardened strong metal. Hydrogen embrittlement.

Nicholas Cage is a beast when it comes to Electrolysis

Good Job!

Good video.

Washing machine drumb should work great for this.

Steel rebar. One amp of current from red wire, but when you connect it to rebar the rebar will jump to 20 amps while the red wire stays at one amp.....lmao.

Is it just me or does this dude sound like nicholas cage?!?!?

nice design, but u could do that stuff with 5min of sandblasting.

Is that the case?? U think this part requires it? U are idiotic yourself.

Many parts cannot be blasted, for example machinery parts where the "tooth" created by abrasive blasting would ruin the surface. Blast nozzles cannot reach where electrolysis can. Clearly you know more about everything than the many experienced machinists, auto restorers and more who have used electrolysis over more than a century.

I literally cannot believe that you can get in a fight with someone in comment section of a video describing such a wonderful design.

Sandblasting does not get into the pores of the steel/iron and neutralize the rust reaction. Chemical/electrolytic derusting (conversion) does. Blasted rust, even after repainting will soon blister through again with new rust. This method also preserves surface detail beautifully. I restore old measurement instruments and graduated tooling and blasting is not even an option. Nice job Albert, and thanks for your subscription to my channel.

Sandblasting pits the metal, Dufus.

1 like for you 1 like for the cat 🐱 🐱

Code requires #4 btw

Insanely overbuilt. It's cool but that gauge ground wire is completely unnecessary.

All of these video are really funny. People use angle iron, rebar, flat iron, all kinds of crazy heavy duty steel......all of which serve no purpose. The amount of current is limited by the red and black wires on the voltage generator. Connecting to ANYTHING larger than #14 wires serves absolutely no purpose. If you don't believe me, try it my way with strands of #14 copper wires instead of rebar. Results will be exactly the same. stupid is as stupid does.

Go titanium.

Your overthinking it. Any container will work. You can get 55 gallon drums all day for free. A kiddo pool is cheap and a great option because large objects like doors and fenders will fit or mostly fit then can be rotated. Small container's easy to find. Just toss in a sacrificial rod and your cooking. You make one dedicated tank and your limited to it's size. You did a good job but it's a lot of work just to find out it's too small.

Can you say over engineering

You are full of crap. There is MINIMAL engineering there,all parts are off the shelf, nothing special made, and works like a charm. You want over engineering, get into GERMAN crap once.