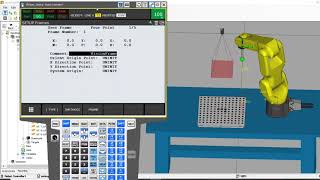

FANUC Roboguide Tutorial

HTML-код

- Опубликовано: 30 июн 2024

- Tutorial video for beginners using FANUC Roboguide software. For full lessons on functionality, tools, etc., please visit FANUCAmerica.com and take our online or in-person training course.

Наука

Наука

Hey Adam! Excellent tutorial. Made a list of highlights to jump to for reference and wanted to share.

0:00 - Intro

0:37 - Building a Cell

1:26 - Software Options (select Motion Package R809 for tutorial)

2:35 - Creating Virtual Robot Simulator

4:00 - Robot in 3D space

4:46 - Joint jog tool

5:14 - Moving Robot TCP

5:32 - Moving the Robot base

6:25 - Adding Tooling

9:10 - Define UTOOL

10:00 - Defining a Fixture vs a Part

10:55 - Adding a Fixture

15:00 - Adding a Part

17:00 - Assign Part to Fixture (Infeed)

19:40 - Assign Part to Fixture (Outfeed)

20:55 - Assign Part to Tool

21:44 - Tool Simulation

23:50 - Writing program in Teach Pendant (setup/payload info)

24:35 - Create program for robot motion

25:05 - Defining Position Registers (Home, Pick, Place, Zofst150)

26:55 - Starting Lines of Code (Uframe, Utool, Payload, Override)

27:27 - Motion Code

30:00 - Simulation Program (Pickup and Drop)

32:00 - Test the Code - Success!

33:00 - Repeat/multiple cycles using For Loop

33:46 - Record Video

35:30 - Profile work properties (cycle time)

35:50 - Run Panel (collect robot info)

This video was extremely helpful as a newbie to robotics coming from PLCs. Your commentary kept it fun and engaging. Thank you.

Mr. Willea, I can't tell you how much your material has been helpful to me and others. Thank you so very much for putting your time and effort towards sharing your knowledge. Thank you Sir.

영상 정말 감사드립니다. 많은 도움이 되었습니다. 좋은 하루 되세요.

Thank you so much for the video. It was very helpful. have a nice day today

I watched your video, practiced 2 times in Roboguide (barely knowing the software) and the next day I was teaching my students how to do it. Big thumbs up. Next up is palletizing (using offsets of course).

Best ROBOGuide tutorial yet! Thank you so much!

It's really nice to have tutorials for programs like these, since there is little to no information apart from Fanuc's manual. Thank you for this !

Thanks, Ian - glad I could help!

This was an awesome and helpful tutorial! Thanks for posting Adam.

Great tutorial, i just started learning Roboguide during this lockdown but found it difficult to do on my own until i found this. Please can you put a machine tending tutorial of a basic load/unloading into a machine, IP/OP pick from conveyor with all the DOs and DIs.

Thank you Adam for the excellent tutorial video! Explanation is very clear and its easy to follow. I have successfully completed the task. The only glitch is the record video results in poor quality video even if I set run time refresh rate to max.

Adam, Great job on this video! I was about to create the same video, but did a quick search and got lucky -this video is less than a week old. We will be using this video for our Robotics classes online content. It fits our needs perfectly. Thanks from me and all our students here at Madison College.

That's fantastic! Thanks so much for the note, I'm glad this video helped. If you have any other specific tutorials you'd like to see, feel free to ask and I'll do my best to upload more content. Thanks again!

@@AdamWillea Hi Adam, Thanks again for the great video. Is there any chance you have a tutorial on using Roboguide to create a simple 2d iRvision offset?

Hi Adam, great tutorial!! Hope to learn more on user frames, how to add user frame in existing program, how to assign in with referencing the robot, Space functions & DCS

Great suggestion! Thank you, I can work to prepare videos for these topics.

Very good tutorial Adam, very helpful!!

Thank you very much for this tutorial video, Adam! Very easy to understand and follow

Mr. Adam this very nice and easy to understand thnk u very much 🤝

great job.. hope you will post videos on advanced topics also...

This is so much better than my college program. Keep up the amazing work!

Thank you! More to come!

Adam, Great job , thank you.

Great content on all your videos. You should position your microphone in another location, the loud smacking noise you make at the end of most of your sentences, is very distracting for folks with ADHD. Like nails on a chalkboard. You have the BEST Fanuc channel on RUclips, I look forward to all your new video's.

It's great job, thank you so much, my teacher.

Love it! Thank you sir :)

Perfect tone for education

Thank you very much ADAM 👍

Thank you so much for your time and effort.

Good tutorial! Thanks.

Thanks very much for this video, great!

This is perfect, thank you!

Love it! Thank you.

Hi Adam! Your video is really great !!! Very very thanks !!! I managed to complete the animation but one small thing still doesn't work properly and I don't understand ... My animation at the start shows the clamp closed blocking the part ... Not empty like your video ... Can you tell me why ? ... Bye !!!

Thanks. Just one question, Adam. I watched your approach and retract linear video and was wondering if you could/would or should use that instead of the z offset PR? And why or why not?

Thank you sir, so helpful

Thank you very much, very nice explanation, very appreciated

Thank You! It's great!

bonus points for the Goldeneye reference

Thanks and it is really very nice:)

thank you very much!

Hi Adam, Any chance you have a basic iRvision tutorial for Roboguide? Trying to do the simple vision offsets we would normally do in class, but now forced to do online. Thanks. Rick

Hi Rick, I haven't created a video yet showing how to test iRVision using RoboGuide, but you have just inspired my next release. I'll work to prepare a video on this topic shortly. Thanks!

Very helpfull, thank you so much!

Very nice and informative video! Thank you for doing it.

What about simulation of that order:

- robot in home position , part is in gripper A (one side of two)

- robot move to table, and leave the part on it

- rotate around the part to grab it from different side from the same table

- take the part with the same gripper A and return in home position

I try already to make two CAD images open gripper (without part), closed gripper (with part in it) none of pick/leave routine worked. Then tried with part present for program run - it showed it initially, but when it goes to the table and the subroutine "DROP OFF" is executed the part is still in the griper, and never showed on the table.. From point A transferred to B as in your video work like charm.

thanks for videos

We are dealing eith IO in class. In class we had to turn certain RO on/off to control the gripper. How can we do this in roboguide. How we know which IO controls the gripper coils? For instance, RO 3 opens the gripper and RO 4 closes the gripper in class. How does this woek on roboguide. ? I understand we can simulate the open/close but I want to so everything like in class

Hello Adam. Thank you for your wonderful Fanuc tutorials. Awesome. Let me ask a question. Why is "External Device" Icon missing in my ROBOGUIDE? Can you please help me about this?

Thanks for the tutorial... Superb... However I get the error "Logging into controller Please stand by" any resolution to this???

Hi Adam, thanks for great tutorial, you're great tutor and it's very easy to follow. I wonder why TP system feels like controlling Windows 3.11? It's absolutely user unfriendly. I'm spending ten's of minutes to figure out how to copy/paste, insert new line etc. Compared to ABB Robotstudio, I can't image writing complex programs, it would take me decades. You can't just write the code, you have to click on menus, then scroll, then select the function, then use the Choice again, uff.

Hello! The TP language has been around for over 25 years, with its core as KAREL structured text. However, there are newer more innovative ways to program a FANUC. We offer the iHMI, ASCII Upload, OLCPRO, and now SCARA robots come with iRProgrammer and CRX robots have Swipe to Teach Tablets.

Perhaps I will do some basic programming videos showing all other techniques! Thanks!

muchas gracias ingeniero soy de monterrey mexico y quiero aprender roboguide ya que solo he usado el 100ib modelo 2000 desde hace 10 años en mi trabajo, tendra algun tutorial para conexion de factory talk hmi y studio 5000

Hello Adam, Great Tutorials. We have One Robot Cell with Arc Mate 100iC/8L and second with /12L. I have Question, in RoboGuide programs goes smooth and fine but same program with Real Robot is horror story. Real Robot (every particular different) with personal deflection with standard calibration method give different result every time when is performed calibration, and calculated offset by XYZWPR is still insufficient accurate. I goes step further and use exchanged calibration method and comes to results where different between RoboGuide readings and Real Robot readings for any point on fixture (welding table 2000x1200 mm) we have delta from 0,7-0,9 mm uniformly over table. What is yours experience with this problem, RoboGuide TP program transferred to Real Robot and fixtures? Just go ahead with great Tutorials.

I'm trying to record an offset like you did in the video. I followed it step by step but after I put the values in for the axes and click "done" it doesn't record. There's still an asterisk next to the = sign. Did I do something wrong?

HI ADAM.. HIW CAN I GET THIS SOFTWARE TO LEARN.. because i work in a bottleing company and has like 7 Robots and I love to learn more about it THANK YOU...🙏🏽🙏🏽

Thanks for the video! One question, what if the default TCP is not visible on the robot?

Sometimes the green TCP orb is hard to see in RoboGuide when you're zoomed in. Zoom further out and see if it shows up larger near J6 of the robot. You can also setup your own User Tool which will help you.

New to your channel, have a questions, will roboguide generate the programme for the fanuc robot controller or do we still have to program the controller?

You can backup your roboguide programs, and then upload into a physical one easily. Check out my video here: ruclips.net/video/v8nw4E-_NCQ/видео.html

please do the Karel programming video( How to create programs)

Will do!

CTRL + SHIRT doesn't work for me, maybe because i have a bit older version? is there any other way to do that in the program? maybe just shortcut doesn't working

Hi Adam,

I am watching and learning your YT tutorial about the "FANUC Roboguide Tutorial". Is it possible to simulate Delta "pick and place" scenario on Handling PRO mode other than "fanuc irpickpro"?

How did you get the triads to have rotational blocks on the end of it? Mine will not rotate and does not have the blocks on the end. Thank you.

ruclips.net/video/Uw2AsKTt6wo/видео.html

Hi Adam, thanks for uploading the video. I have a question regarding Setting up Handler on Faceplate. Whenever I am uploading Cad data for handler ( same process as shown in video at 6:45 mins), it does not go to Robot Faceplate at 0,0,0 location for X,Y,Z.

Instead its staying way off. I have to move it manually in order to fix it with Faceplate which is time consuming and not so accurate too. Do you know Anyway to solve this issue?

Thanks ,

Mohnish

Hello Mohnish, the most common issue with that, is the Origin of where 0,0,0 is in the CAD file where the handler was designed. Please check your CAD program (Solidworks, AutoCAD, Inventor, etc.) and set the Origin of the drawing to be at the point you would like to contact J6 Faceplate.

My name is Julio, first comment is that your canal is a lot useful. I'm a teacher of robotics and only way now for teaching is use simulation in remote activity.

I have now a big problem, I try make simulation of the arc welding and don't can show the beam of welding and the light arc.

Do you can me show how make necessary adjusts?

thanks a lot for your attencion.

Hello Julio, thank you for commenting!

Unfortunately I am not formally trained in the Arc Welding division of FANUC, this is a special team within our company. Please contact your local support hotline for details.

If you are in the U.S. you can call 888-FANUC-US or connect on fanucamerica.com

Hi, love the tutorial but have a question. I'm having trouble with the SHIFT + CTRL movement, when i try and use it the robot can't seem to decide how its moving and kinda glitches out then reverts to it's original position. i have no idea why its doing this and can't find a reason for it as I was just following along with the video. Help...

Howto setting multiple gripper?

Do you have a video on how to use the teach pendent in Roboguide? At 24:00 you run through the teach pendent so fast I cant see how you're doing any of that. Even slowing the video down I can't figure out how you entered text in there or any of the values and in the video I can't see what you're clicking on or double clicking on, etc. Everything else in the video was easy. Just hit a wall when it came to the teach pendent

Hi Adam i have one question that in my program run time gripper not open and close and gripper not pickup parts. But in your program it is showing that gripper actual picking the part and placing it to table. Please suggest how to solve this issue

Hi! Please click on the icon with "Pause Play Stop" signals to open the Run Panel. Scroll down and make sure the checkbox is checked for "Collect Profile Data/ Enable Pick and Place Animations". That should get it running.

@@AdamWillea Thanks Adam

I have a doubt you first do the instruccion override 30% so velocity it's on 30% and then the you've done the instruction "J PR[1:HOME] 100% FINE" so the question is in this position velocity is 100% the velocity robot can do or it's 100% velocity of the % of velocity described in the previous override? nice video

Good question. The OVERRIDE % is a multiplier to whatever is in the code. So...

J P[1] 100% FINE with a 30% Override is same as: 100 x 0.3 = 30%.

Also...

L P[1] 2000 mm/sec FINE with a 30% Override is same as: 2000 x 0.3 = 600mm/sec.

Also....

J P[1] 50% FINE with a 30% Override is same as: 50 x 0.3 = 15%.

Hope that helps!

Where is the robot home position ? please give me your robot's home position(linear and joint dimensions). THANKS

I want to change this installed software from Japanese to English..Please tell me how to change..

Is this software only used with fanuc robots??

I have another type of robot that I made for my graduation project.. Can I program it with this software ??

Hanzhen harmonic drive gear , robot arm gear , over 30 years experience

you go thru this stuff so fast. is there any other resource for someone in there very first Fanuc class? our class expects us to know how to operate these things already and i have no clue. i have made it to 23:59 and i am trying to change to payload and it won't let me. i enter 35 and it won't let me and it changes back to 165. also cannot type "fun" it just goes back to all x's

Please make sure the virtual teach pendant on/off switch is turned ON or it will not let you do any work.

Notice on the TP home screen there is an icon for "Tutorial". This can be a helpful way to get started. There is also a good tutorial in RoboGuide under the Help menu. Beyond that, it is just practice practice practice, and taking the formal FANUC training courses.

@@AdamWillea there is so much to just get to know how to use the software. I need practice on just operating the robot physically, not virtually. the software seems harder than the real robot

Where did you get downloading?

Hello Adam , I have a problem, when ı added the grapper ıt or add another fixtures wıll not seen ın screen , I can nor see that ., ı dont know why , can you help me ?

Hello - if you are adding grippers, fixtures, parts, etc., and they do not show up, please first double click on them in the cell tree on the left and verify Visibility is checked and turned on. Also make sure the transparency is not turned to 0%. If nothing fixes it, please contact your local tech support as you may have a software issue.

Thanks a lot for all of your videos Adam, I have leaned a lot from you.

I have a question, I am trying to import multiple different parts into my cell, the problem I have is, I import the 1st part, position it correctly in the fixture, but then when I import the 2nd part into my cell, the 1st part is moved out of position, is there a way to create multiple PartRacks maybe? I would appreciate anyone's help.

Try importing just one part, then copy + paste from the parts tree. When you make duplicates, it should place the new one exactly 1m above the original. Then you can repeat the process and position everything as needed.

@@AdamWillea Thanks for getting back to me. I should have given a bit more detail sorry, the parts are 3 different components, and have unique CAD files. They make up a complete part.

@@RA-rw3xo I understand now. Yes, the easiest think you could do is use a 3D CAD program to consolidate all parts then export as a single IGES file. Then use that IGES to import into RoboGuide, and then all will appear correctly.

Hello @@AdamWillea I need the 3 different parts in different locations in the cell. So I have a bottom part, middle part and top part all in different racks. I need to pick them all individually then put them together on a turntable. When I import the bottom part, place it where it needs to be in the rack or turntable, then import the middle part it shifts the bottom part, and then I can't move them individual.

Is it only possible to have one PartRack?

I have a question, I can use the button backward and forward? After the simulation

Absolutely! Using the SHIFT+BWD or FWD buttons will run the robot through all TP motion, but simply will not pick up or drop the car. The simulation parts will not work unless in Auto mode, but everything else will.

@@AdamWillea thanks

Hi Adam, my robot is not moving to position when I click in move to, only tcp frame is moving. Please help me

Hi Pedro. If the "Move To" button is not working, you must check the triad of how the part is placed in the fixture vs. how it is placed in the gripper. I normally see users with symmetrical parts that LOOK pickable, but in reality are upside down or backwards. You will need to go to your Fixture properties, then Parts tab, then Edit Part Location to see the part XYZ triad. See how that aligns with gripper.

cant figure out how to flip parts to make them face away from robot. i forgot how to jse this software in the past year.

If you are talking about how the part is picked, carried, or placed, make sure to click on the "Fixture" where the part is, then go to the "Parts" tab, and click "Edit Location". Then you can type in values or use triad to click and drag part around. Good luck!

If Roboguide is awesome does it work with 3dconnexion devices yet? I mean 3dconnextion has been around for decades.

my robot came up with a yellow ball on end tip, i did everything you did. how do i get rid of the yellow ball?

This could be a couple issues, likely just a positional warning. See if you are able to jog the robot via the TP or by clicking the yellow ball and dragging the arrows to move around. Green ball is normal, Red ball means "unreachable", Yellow is a minor warning of sorts. Also feel free to contact our support hotline at 888-FANUC-US (if you are in the United States) and they'll talk you through any errors.

Adam Willea oh. It may be green lol. Sorry.

How can I add CRX series in ROBOGUIDE?

12:59 I press control shift and the robot doesn’t move. Any ideas?

Why i cant just download it?

Something must be wrong with my blower for my vacuum because the case never leaves the conveyor. Only at simulation for now. Lol

How can i download this program? Thanks

Hello - please contact your local FANUC support (check via our website) and ask for a trial version or purchased version of RoboGuide.

I can help you , send me An e-mail interkalados@gmail.com

Fun ? . Là sao để viết

I cant write in my keybord ı didnt fix that , can anybody can help me ?

Nice tutorial. My god programming with this software is horrible.

You might want to turn on your mouse highlighter when making videos so it is easier for humans to follow along.

Good suggestion, thank you!

Can the virtual robot communicate with an REAL, physical, on my desk, AB CompactLogix PLC? If so, how can I make that happen? FANUC does not seem to know much about this question. Thanks.

Hi Adam, i need help with offset programming can you provide email so that i can share for what purpose i want to program the robot