ZIP-R Sheathing Review (Feat. Steve Baczek)

HTML-код

- Опубликовано: 27 июн 2022

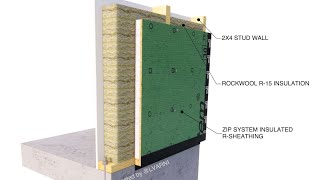

- Zip-R Sheathing is an easy way to get a thermal break on the outside of your house! Matt Risinger and Steve Baczek break down the options and benefits of this Zip Sheathing bonded to PolyIso insulation.

Go follow Steve on Instagram: / stevenbaczekarchitect

Subscribe and follow my Podcast on Apple or Spotify!

Apple: apple.co/32AOwgU

Spotify: spoti.fi/3FXNg4X

Sign up for our twice-weekly newsletter:

buildshownetwork.com/newsletter

To sponsor a video or advertise with us visit:

www.buildproductions.com

Want to learn more about building? buildshownetwork.com/

Build Show Network on Instagram: / thebuildshow

Huge thanks to our Show sponsors Builders FirstSource, Polywall, Huber, Rockwool & Viewrail for helping to make these videos possible! These are all trusted companies that Matt has worked with for years and trusts their products in the homes he builds. We would highly encourage you to check out their websites for more info.

www.bldr.com/

www.Poly-Wall.com

www.Huberwood.com

www.Viewrail.com

www.Rockwool.com

This contractor is also very good at conceptualizing and verbalizing these things for the layman. I appreciate that.

I'm the architect, but thank you

@@stevenbaczekarchitect9431 lol..........

Probably the best Ryan’s ruclips.net/user/postUgkxGZedDTcDfgD7fG_uU4esfx_EgxzlY2_1 Plans on building a shed is hardly ever found. And Ryan takes the mystery out of different types of foundation options, etc. He even shows how to build a shed with different designs. Very comprehensive, covering different roofing materials, siding, etc.

Steve is the man

We are all trying and learning buddy

You gentlemen gave me a few characteristics that other reviews failed to.provide. YOU GET AN A. Congratulations!

Well thank you

I have a love hate relationship with these videos. We are looking at buying a new build house but it is so difficult because so few builders follow these practices. I love seeing how it should be but I hate the fact that the chances of me getting how it should be is very slim. I can always dream.

For this very reason I am going the "Owner Builder" route...

General Contractors will take 20% (give or take 5%) of the total budget, and they get easily annoyed by the owners asking questions or requesting something be done a "better way".

They'll skimp on every detail they can get away with to put a few more dollars in their pocket, not caring one bit that this is the owners "dream home".

I'll find the sub contractors myself, I'll inspect their work, I'll make sure materials have been ordered... The biggest headaches are gonna be dealing with the bank, inspections, and most likely delays or no-show contractors.

But I'm only building my forever house once, so I'll suck it up :)

@@clintforest44 You’re going to find out that “forever” ain’t forever.

@@seanm3226 I'm sitting in my sixth forever home as I type.

@@seanm3226 OK, Mr. Obvious.

@@clintforest44 A somewhat similar route, I have a builder friend that is charging me 10% of material cost to be my general contractor plus I get his discounts and the subs that he's worked with for years. I did have discussions with him on how I want things done because he's been building for 40 years and he doesn't like change. Using Zip-R was one he wasn't familiar with.

Some contractors are surprisingly naïve outside their experiences. The stairs to the lower level needs to have a post at the bottom step to carry the trusses above and he said I should just wrap the two laminated 2x4's post with hardwood to match my millwork. I said I'll just laminate four oak 1x4"s instead of using 2-2x4's to the same dimension (3" x 3.5"). He asked me if my laminated oak 1x4's would be as strong as yellow pine. Huh?

Steve is great, like his way of explaining things. Pls have him on more.

I agree LOL

I used zip-r on my house and had a ‘metal lug’ cast into the slab. It’s a 1.5”x1.5” step that goes all the way around the building. The zip-r then sits down in that helping to seal the bottom plate. I used some big stretch to create a backer and the zip liquid flash as the final seal between the zip and concrete.

Does the metal lug sit just below the seal plate, or is it attached to the seal plate?

lets get some pics of this

@@sampickett3843 It's cast into the concrete slab, so the sill plate sits at the interior slab level, and the Zip-r hangs down about 1.25" below the bottom of the sill plate. From the outside though the Zip sits flush with the perimeter of the slab so most people would never know it has exterior insulation.

@@sampickett3843 It's cast into the concrete slab, so the sill plate sits at the interior slab level, and the Zip-r hangs down about 1.25" below the bottom of the sill plate. From the outside though the Zip sits flush with the perimeter of the slab so most people would never know it has exterior insulation.

@@srt4b The green face of the Zip sits flush with the outside face of the slab, so it really doesn't look very 'different'. The only thing that overhangs the slab is the thickness of the siding so even experienced builders probably wouldn't guess that the house had ext. insulation. BTW, I've been very impressed with the performance of the R-6 Zip-r. I haven't yet insulated the stud cavities, but the inside is already staying cooler than a conventional 2x4 insulated house in the Texas heat without AC .

This was the easiest way we figured when we built our house, we just set the foundation walls out 2 1/2 inches wider so the zip R 2" would be flush with the foundation wall, kept the zip up about 1/2 inch and spray foamed between the foundation and zip and liquid flashed the connection between foundation and zip

Sounds good. How much did the extended foundation add to the cost though?

Great idea

@@ericfranke1637 it really didn't add to it, we just moved it out 2 inches all the way around, so it's not any thicker, it's a slab on grade

With the sheathing held off the framing by relatively soft foam, I’ve gotta believe the shear (racking) strength is drastically reduced.

Insulated Studs and Sheething.

Seem like an absolute industry standard of the near future.

The thing I like about exterior insulation of this type is that it's less assembly to worry about. Anytime you can eleminate a step, that's a good thing.

Every time Matt changes his vocal register to say his trademark “oonnnnn the Build Show”, I’m watching Steve’s face and it’s always entertaining

I love Matt's videos but I have to jump over "Leeeeeeets get gooooing" and "Ooooooon the build show". Seems super used car salesman for me and damages credibility. I guess if I were in pro trades I'd love it.

@@danlake7970 I Get it - I'm thinking Steve knows that all that over the top stuff is For the Brand

Gotta have fun always buddy

Matt, you asked when should the insulation be to the inside of the sheathing vs outside of the sheathing. All I got was there are different rules for different climates. Would it be possible to go over those rules for different climates, the pro's and con's. You go discuss freezing climates on a regular basis. I live in southern California, 100+ degree days don't feel good either. Thank you for all the education. Just a suggestions Sir.

different rules for different applications not different climates. All 3 different ways accomplish the same thing.

The Cold Climate Housing Research Center has some great videos on this. Particulary this one: How to: REMOTE Wall System Part 1

i wish they did mineral wool, then vapor barrier wouldnt be so questionable because here the foam then osb then vapor barrier, i feel like these would trap moisture ? Assuming this foam they use is perm though so prob not

I am in Minnesota. I plan to build in the next couple of years. Thanks for the great information. BTW last year at the farm, the build location, near Duluth MN go to -32 for a streatch last winter.

Good stuff. I'll keep this option in mind when I build my garage/apartment.

Awesome stuff Matt, thanks for the info! 😃👍🏻👊🏻

Form and function! I am absolutely loving learning about insulation. Our environment is depending on these changes to net zero all the energy our current houses use. I would be honored to build a house with Steve.

Thank you!!!

thank you. great information.

Could you do a 2x8 bottom plate and notch out the insulation so that the sheathing ties into it directly?

Awesome work guys, love the content! :)

Thank you

Grear show! Thanks!

I like Steve. I like that he is telling it straight.

I do my best my friend - my word to me, is everything

Matt, Steve,

Excellent Educational Video. You two provide an outstanding collaboration and thought provoking discussions!

I loved the explanation that various exterior sheathing insulation options are NOT an issue of which is ultimate but more related to the set of Rules that go with the selected exterior insulation opinion!

I love the Dr. Joe perfect wall on Matt's house, BUT for all the non-standard construction processes (and without a pro like Matt on the job), I wonder how much net value and cost it is over a Zip-R (R6 or R9) with a 1-2" flash of CCSF and blown insulation or RockWool inside (for my Southern-NC Coastal area)???

Man, you guys get at some Excellent aspects like climate zone options and regional code issues like Jake's 2x8. I'm thinking the Tape detail at bottom of Zip-R would be better at stopping bugs and improve Air and Vapor boundry.... as long as the tape sticks for 50+yrs! Also, I'm thinking the insulation blanket should cover the Sill plate would be best???

Cheers,

Eric

#longlive our buildings!!!

Thought of this long ago. Damn it. Would love this on my western facing home in sunny California.

Steve was brilliant in this one.

I totally agree - thanks!!! lol

One thing I've noticed, in so many of these videos dealing with Zip-R, and it's benefits, is they don't ever seem to talk about the wall to roof transition, and what to do with the room sheathing. Zip-R isn't certified(?) for roof usage, like it is on the wall, so you still have that thermal connection compared to the thermal break Zip-R has in the wall.

I think in one of Matt’s videos the builder brought in an engineer to spec out and vouch for Zip-R on the roof. As I recall there wasn’t a lot of weight on the roof.

I beleive you can install a layer of plywood then zip-r over the plywood for a roof.

@@ericwotton2046 not a bad idea. Basically turning it into a SIP roof system.

search for "Monopoly framing" on RUclips, Matt has done a few videos on it. regular Zip roof sheathing intersects the wall sheathing and gets sealed with tape, then any overhang/eve is framed outside the envelope. Exterior roof insulation is laid over the traditional Zip.

@@kschleic9053 yes he used modified lvl's for rafter tails and did two layers of 2 inch polyiso. I've drawn out the details on sketchup. Plan to use that assembly on a post frame I'm designing.

I used Zip-R 2" and 2" rockwool comfort board over the top since we're in high fire area. Donner Lake in CA. Closed cell in cavities. Was pricey but incredibly comfortable

Nice, 2x4 or 2x6 framing?

@@DAMMDAUGHTERS 2x6. Some major structural beams on lower level cinder block garage so had to. I wanted them anyway and engineer said they had to. I wanted a very efficient home. Haven't done blower door but it's very tight

@@jwristen24 that's very similar set up what I want to do. Hopefully as these products become more popular the prices go down a little. I bet it was pricey but worth it

@@DAMMDAUGHTERS very worth it. A small fire in the stove and you're opening windows lol. Triple pane Jeld Wen's. Doors aren't high end passive so that was about the only area I saved lol....

yeah, imagine if they had partnered with a mineral wool board company like owens/rockwool :( i wish!

What is the perm rating of this foam? How is this not a double vapor barrier?

Great video, I am remodeling & updating a Florida home that is constructed with typical CMU blocks and I think could benefit with a R12 panel that could provide the WRB, insulation, sheathing for siding updates and a chase for Elec & plumb adds and updates. Any thoughts on fasteners and assembly specs? thanks, PETER

Looks like great stuff. I’d use it IF I could find it.

I like the t shuds for framing, also make foundation wide enough to have full wall, so outer is flush with foundation. N run a thick system on exterior with spray foam inside for max insulation in the end overkill

Would have been very helpful/useful in this type of video when discussing one specific product to state the current price of Zip R vs standard OSB and what it means cost wise for a typical new build. I know there are some additional benefits but the biggest reason to use Zip R is the savings it would provide in heating and cooling and calculating this is a very complicated thing.

Matt does have a price comparison video of different wall systems, including zip-r.

@@taylorseigler I believe that was pre-pandemic and I'm sure current prices are drastically different.

It's all over the place right now. Just the sheathing was going for like 86 bucks a sheet a few months ago from home depot. Thats not even the insulated stuff. Think its back below 60$ a sheet now but it's horrendous when they've been doing.

By the time we edit and post the video the $$ info is out of date.....

Framing! Now this is what got me hooked on the channel. My kinda video

Mine too!!!!

10/10 Great Video!

Always good to see Mr. Baczek!!

I just finished a Zip R house and it was more difficult for this reason. In my area, Zip R is not available in 9 or 10' lengths. Only 8' lengths. Thus there was a ton of extra blocking required to compensate. I'm still a fan of the product; just wish we can get longer sheets.

never seen even non-r zip panels in my area...

@@zefrum3 most builders supplies have to order it. Be prepared to wait and to pay out the ass

Is it harder to use, because it is heavier?

@@Raymond-mk8cb Because of all the extra blocking required for 4x8 sheets.

If you get an aluminum flashing custom bent you can have it wrap around the bottom of your ZipR sheathing and back up so you can scre it into your studs then slide the sheathing inside. Would make an easy to seal joint that you would not rely 100% on the flashing tape. In that case i would use a fluid applied in behind on the bottom to seal the flashing to the studs as well as to the face of the sheathing. You can then put your flashing tape over top just for overkill

Metal flashings circumvent the insulation. The wood and flashing tape detail is more effective at retaining the R-value that was paid for.

A major advantage of the Zip R versus Zip+exterior insulation is when the inside moisture finds a cold surface inside the wall cavity, the moisture will condense on the waterproof poly-iso, instead of on the un-faced OSB side of the Zip, which is vulnerable to any moisture.

Is that really an advantage?

With a proper ratio of interior and exterior insulation, the exterior insulation setup will never/rarely let the sheathing get cold enough to condense. That said, exterior fastener points and seams could be cold/problem points in that setup. Meanwhile, Zip-r leaves all the sheathing itself out in the cold. You would almost certainly be relying on the poly-iso as a vapor barrier, but nothing is perfect. At the least you have unfinished seams exposed to the inside around the edge of every panel - with varying gaps depending on quality of install.

More importantly, how is condensing on the inside of the poly-iso itself a good thing? Sure the poly-iso might not care, but the framing certainly will, the cavity insulation most likely will - and that poly-iso isn't going to be great for letting it dry to the outside very quickly.

@@chuckuni5366 actually water won't condence on the back of the Zip-R sheathing so long as it's thick enough. Just as you said if you add extiror insulation you effectively move the dew point further out. You can easily calculate if you have enough extiror insulation to prevent any dew from forming in the wall cavity. Though I would still recommend the use of a smart vapor retarder in cold climates. Also blocking is required at all sheathing seams in almost every municipality.

@@Ilove3SGTE I realize that this is the case, but just pointing out that condensation on the inside of the cavity is not a great thing, foam or not. Arguably worse if it were to happen with foam as your would be reducing the ability to dry it out.

What happens to this zipr if cedar prestain shingles are installed without a rain screen?

@@chuckuni5366, agreed. Fundamentally one can build a great wall system with Zip-R or Zip/OSB + weather barrier and exterior insulation. One should always plan to put enough exterior insulation to prevent condensation from forming inside the wall cavity in the first place, based on the yearly temperatures and humidity the house is being placed in.

as an architect I love zip .

Thanks for another great video! I wonder if I'll be allowed to spec this product in my conservative agency?

Steve you the man!!! Littleman with Glasses approved 😂😂😂

Love that guy!!

Matt- I live I Leander and recently found out I have no tyvex or waterproof under my hardy board. So now I have to remodel the back of the house. What would you use in Texas? Thinking zip system with r value. Then hardy board back. Really worried about water proofing

Súper didáctic, Impsa not sure if such a product is in argentina, ill try to arrange something similar

Steve should write a book on Wall details for high performance homes

sounds riveting

Steve needs about 6 more hours in a day lol

I used Zip R-6 on my home myself. I’ve heard no one before mention that the spec calls 1.5” minimum penetration and .131 nail. It isn’t just a longer nail, it is a thicker framing nail. You go to an R12 and you have a 4” nail. Where do you find a gun to shoot 4” nails? I used ring shank 3-1/4” .131 as my “belt and suspenders” and a pressure treated 2x at the bottom outside wall to sit the sheathing on. All things Matt has shown, but the nail size still caught me off guard.

Several companies make nail guns that shoot long nails. Fasco's "jumbo nailer" shoots 4" up to 6.25" nails, it's pretty impressive.... And scary 🤣

@@sixtomidnight1492 sounds like a great Wire and pipe finder if used incorrectly.

I'm building a home with Zip-r12 and I bought two Bostitch "Big Bertha" nail guns to shoot 4" nails. These guns are big and heavy, so the walls will be lying down for attaching this sheathing.

what did you do for air and water sealing at the bottom over your 2x?

He made that shit up. Actually he scerwed up as 1/2" sheething requires 1.5" galvanized roofing nails and 25/32" sheething requires 1 3/4" galvanized nails. So, that is 1" of penetration, not 1.5" penetration. Who can shoot 4" nails? My gun shoots 3 3/4" nails and I have yet to see a gun which cannot do this. This means with standard 1/2" sheething can have 2.25" insulation using standard nails using a standard nailgun. Same goes for 3/4" sheething and 2" of insulation.

i’d love to see some sort of composite material used to replace the wood used for sills. still going to have cold concrete and a new material would be a good thermal break for the base of the building.

Use Amvic ICF for foundation

Hi Matt, big fan here for a few years now. Can the Prosoco R-Guard system be used over the Zip R-sheathing system? Would like your expert opinion.

Two guys who know their stuff

Thank you

If I won a sizable lotto, I would not buy a vineyard or a cabin by the lake. These guys would be getting a call to get me a home to write home about. Thoroughly enjoy the details and camera on explainations.

Nope. Take the vineyard or cabin. You’ll find a thousand guys who can build a quality house.

@@seanm3226 Pretty sure you can hire Matt or Steve as consultants

Matt lives in Austin Texas. Housing prices have gone thru the roof the last few years, especially since Tesla and Apple decided to build sites there. You almost have to win the lotto to buy a home there now.

Steve is great at his job.

Thank you - much appreciated

What the comparison if I sheath first then run osb or I run osb first and sheath exterior insulation. Does one way work better than the other or in a perfect world just do both ?

Interesting.

How about drip edge (pointing down) to cover the bottom edge.

Here is a question for Matt or Scott , Steve B or this community. It was about Scott Trues last vid on Matts channel recently. Scott talked in the vid about Lstiburek suggesting placing the drainage wrap over the sheathing but inside of the rigid foam. I listened to Lstiburek in another vid suggest that in case water got between the sheathing and the most inside rigid foam it would have a space to drain. In doing more research there are building science people who do not include that drainage wrap over the sheathing and only over the most exposed rigid foam. We saw that Scott found even the dashes of liquid flash may not be effective to create enough of a gap. Remember, there is hydro tension to consider if the air gap is not wide enough. STeve Baczek talked about this on one of his vids. Can someone clarify, with being in zone 7 Canada, if that drainage plan is really needed? I talked with a builder here on Prince Edward Island, CAnada, where I live, and to eliminate any rain getting in between the rigid foam we were thinking of using the "brake" to bend aluminum to cap off the top. That would be the only place water could get in...maybe rain hitting it even under the eaves due to rain...and we are getting a lot of hurricanes now so wind direction is changing and more forceful. I continue to research and hope a few of you will answer. I might copy and paste this comment and add it to Matt's channel comments and Steve Baczeks as well. Cheers ☺🇨🇦 Long live our buildings👍

Matt, what do you do for the condensation that will form on the interior of the polyiso, as the stud contact? I build in SW Georgia.

How are y’all detailing inside corners? Ripping off the wood from the foam the width of the foam?

If you do that in tx would it have problems with moisture?

Thank you

Welcome

Could you use this to retrofit a solid brick house with insulation?

So I know ZIP R is a savings for a builder because your installing 2 products at once and time is money but I have a dormer that needs new siding and I want to beef up the insulation under the siding. I truly do believe in ZIP but because I’m a DIY’er and don’t have a commercial account ZIP R is $144 a sheet for me. Can I achieve the same product if I do 1 1/2 foam board and zip over the top? I can make that assembly for about $80 per 4x8 sheet.

I see you apply the zip sheeting in a vertical method. What happens when you have studs that start warping on these vertical joints?

Does Zip make insulated roof sheathing, or can the sheathing shown in this video be used under metal roofing?

Why wouldn’t I use regular zip over rigid foam board? How would this work with steel framing?

Seems like with the condensing point. Does it make more sense for Tx to put the insulation on the outside of the sheathing?

Yes, it does. Zip R isn't a perfect wall. Matt did it right on his own house. Zip R is just easier.

Last couple times of purchasing Zip panels I’ve noticed the quality control is in need of revamping. Of 40 sheets at least 10 were coated where the material of the board looked chipped out. Also the overall strength of the board seemed to be lacking or I got a lot stronger swinging a hammer and I really doubt that as I’m 53 with arthritis and hate swinging a hammer.

Matt, You can get the same performance as Zip-R with just using 2X6's 24 o.c with Closed Cell foam. Thermal bridging becomes less of an issues with 2x6 and greater studs. This is a much cheaper solution too.

He does and did do that. The zip-r is additional.

depends on several factors. Have to use 5/8 drywall with 24 oc & also cannot use 20 oc joists with a 24 oc exterior framing I believe.

I FEEL ALL zip is overpriced bullsirt!//Taping an OSB SHEET THAT COSTS more thandouble is pure silliness! WE tearoff roofs everyday //raw 0SB...that is 35 years old and still perfect..and taping with tape that costs 500 bucks on a house that will leak IF ITS NOT ROOFED RIGHT IS another waste!SPENDING MORE ...300% MORE IS NO BETTER!

It helps - but it is not the same....

Show your data

Does the extra 1" just hang over the foundation? Or do you place the mudsill and inch inside?

What would interest me is with the foam against the studs would there be a significant loss of the shear strength that would potentially wear away at the foam causing it to get worst? Would it not be better to essentially put an additional layes or plain OSB or plywood which you can then add a small ledge at the bottom bridging the foam gap so you have no potentially exposed foam

I feel like there is a loss of shear strength idk if it’s enough to matter but I sided a house with this stuff and I think with the siding it was like over 1 1/2 inches thick. We couldn’t even use a coil gun for our hardy board because there weren’t any coil nails long enough to hit a stud so you have to use a fuckin framing gun and turn it down all the way. Not only that but on a lot of the seems I saw places where the sheets weren’t even touching the studs like some sheets were sticking out a 1/4 past the one it’s butted into. It could be the people who put it on but I only ran into one house that’s ever had it so far. I will say it is nice that you don’t have to tyvek it though. You just have to tape the seams.

re Oct 29 2019 vid, are plans available for Steves blue party barn ?, would need to be tweaked for Canadian code

I’m want to redo some insulation on our current house. We just put new windows in here in MN. Is there a system when reducing siding to add insulation. I’m willing to even take down sheet rock and spray foam. Any recommendations out there?

What fastener have you used for the R12 sheathing ?

So this is all cool stuff but most of us are not making a new house. What you some things current home owners with house built in the 1970 to 2000 can do to insulate and improve there house? Whay are some no brainer improvements to all ready finished houses? Radiant barrier, window caulking, window film, AC balancing, performance test?? i am really not sure

What you double sill the bottom with a 2X4 on top of a to 2x6/8. you get the strength of nailing the bottom of the zip and a ledge to hold the zip. Follow that with the tape to air seal the bottom. Trifecta win.

Mr Risinger could a person use the zip roof sheathing the brown stuff for an interior like bathroom of kitchen floor you know where there is high water areas I have a leaking ceiling in the bathroom from a bad roof install and i fixed the roof but i never want water to come though the ceilings again obviously

Hi Matt, in Joe Lstiburek"s perfect wall the foam board part is facing the exterior but with the Zip-R the foam faces the interior of the house, one of Joe's main concern is to protect the structure of the house, i believe the OSB is big part of the structure, that's why the order for a perfect wall based on Lstiburek is cladding/siding, foam board, osb, insulation,etc. how would this Zip-R board affect the quest for a perfect wall, and how things will dry if needed using this system? i don't think there's any permeability from the polyiso foam.

wouldn't have been better to have the foam on the outside?

The order is cladding/ siding, air gap, then outsulation (insulation outside), then water air barrier, then osb. The barrier is to be vapor permeable but block water. Moisture moves from warm to cold. I would build with regular zip and the use inso fast panels for outside insulation.

I love this stuff .. I just hate the price increase .. yikes ! wish i could do my plaster / lathing / clapboard 20's bungalo with this system ... one of my issues is what to around the windows trim-wise considering the thickness of the zip-r ( my windows are wood and newer double hung low e double glazed)

Extend the windows is not difficult if using old, but if new, just buy windows with deeper frames... This is not difficult here. True, you can't be STUPID when doing it, but adding frame length is not difficult. If you need to hide the line(most likely) , add a new sill plate inside.

LMAO

I'm planning a ICF for the DFW Area. I want a Solar Roof and understand our latitude is 32 degrees or 7 1/2" per foot run. I'm doing a concrete roof and planning Spider Ties with 2"ISO X 5/8" Huber Zip Sheathing. Is ISO Insulation compatible with concrete?

If ICF is two layers of insulation with a concrete sandwich in the middle, why would you want an extra layer of insulation?

For shear walls, I guess that longer nails through foam will transfer the shear? what nail specs will engineers allow?. Is that insulation creating a radiant barrier on the inside?. Why does that sample piece look like there is and space between the panel and the foam? is the foam not attached?.

So would you do Zip R, or regular zip with continuous rockwool?

Zip R is one trip around the moon

Would you be ok using closed cell foam with the Zip-R? Some worry about a double water barrier.

I have done it. You need to ensure the CCSF installer is top notch. The fear would be for moisture laiden air to find its way between them. (in colder climartes)

@@stevenbaczekarchitect9431 thanks, so you'd have less concern in a warmer climate, like Texas, or more?

Is a poly (vapour) barrier still required on the inside since the exterior Zip R has the weather barrier built in? If poly was added inside wouldn’t this trap moisture inside the wall?

No poly on the drywall side. You can use a smart membrane if you like but regular poly sheeting will trap any moisture in the walls with both wall sides being low to no perm. Rockwool or spray foam with no interior vapor barrier. Not sure if fiberglass would be a bad choice or not with no interior vapor barrier when using Zip-R but you need to make sure you're using the correct Zip-R for exterior R-value - depending on what zone you're in. I used Zip-R12 in Minnesota.

Do they make 5/8 insulated sheething capable of roof sheething?

Would it be better to leave the Zip-R12 sheathing short of the jack (trimmer) studs and use 2-7/16 x 1-1/2″ furring boards on top of the jack studs so the window flanges have solid wood to nail to or just nail though the 2-7/16″ thick sheathing into the jack studs using 4″ nails?

I’m concerned that the framers might not get the R-12 sheathing up tight to the furring boards and leave gaps that will need to be foamed before using Zip tape. Huber says it’s OK to nail through with 4″ long nails around windows but my builder is concerned that the windows might not adhere long term to the wall and could move with any movements of the sheathing due to 2″ of foam sandwiched between. With furring boards, I’d lose the exterior insulation over the jack studs and top/bottom around all windows. My builder doesn’t think that’s a big deal. It’s my call, of course. My windows are very large with some 132″ x 72″ high.

Your opinions would be greatly appreciated!

what did you do? Watching the video I thought of this exact predicament. I think I would have just gone with the longer nails, but then I was thinking the R-value of the window frame is probably about the same as the R-value of the wood, which would be wider in that area.

So neither way could be distinguished as substantially better than the other way, except for the feeling of a large window hanging more securely. but furring each window with additional supports is time consuming.

Ended up using 4" self tapping washer head screws with a star bit driver through window flange though the Zip R-12 and into the jack studs.after using regular roofing nails to hold the window in place to sheathing (screwed immediately after nailing).

Never have wished for winter before but looking forward to see how toasty the new home will be with lower energy here in zone 6a.

@@markfairbanks3533

Is zip sheathing ok to use under a stucco finish?

Trying build a small net zero home. My worry about the zip R is vapor can't escape? How do you account for that

Questions: Is the inside face of the zip board against the studs a radiant barrier covering? And if not, could it be painted with a radiant paint? Also, if you use a single headed nail to attach the sheet to the studs don’t you lose some strength structurally since the head of the nail is firm against the foam board which is easily compressed and would allow the board to move around? Would it be possible to use a double headed nail to attach the sheets or just screw it to the studs down to the face of the inside board and use a filler at each attachment point? My 2 cents from someone who knows nothing about zip boards. Thanks for these great informative videos, watch them all the time.

the ply sheeting is on the exterior, where the nail would go. the poly iso is between the studs and the exterior sheeting. nail goes through ply first, into iso, into stud. nails have a stronger shear strength than screws unless using specific screws. double head nails would not work as the lower head would hit the ply and the higher head would still be above the surface of the ply. if you tried hammering to the next head you would create a larger unsealed hole, have no holding, and leave the ply exposed to any possible moisture. I am by far no expert and can be corrected on any of this. i have built some things in my life and understand (some) advanced building methods like this.

You got me thinking. I like the insulation on the outside. What if they engineered it so the foam is attached to the green side and then they create the hollow tubes for screw attachments and fill them with spray foam in the field. Then you get the perfect wall.

@@4our5ive61 Appreciate the reply. So the board facing out sits on the foam and you have a nail or screw thats an inch or so away from the stud buried in foam. Not liking that at all structurally. I think I’d rather use a 5/8” or 3/4” radiant barrier board (cool decking) and then attach Grace Ice and Water Shield rubberized adhesive underlayment to the radiant board and then attach your preferred siding to that. I’d just use a high R-rated insulation in the walls. More than likely my method is not any cheaper but I’d sleep better at night. My opinion whatever that’s worth. Thanks again.

What about Zip liquid flash to seal that up?

Zip with t studs, how you get proper mail penetration?

Good luck getting a termite bond using that. Around here they specifically state they won't bond a house with exterior foam. That's why I'm thinking along the lines of bringing in some Comfortboard.

But in this case would it be considered exterior since technically it is behind the exterior sheathing?

@@explorenaked As Matt mentioned, he mentioned a concern about insects burrowing into the foam, termites will eat right through foam. There are some termite bonding companies that will bond it but only because of specific system they are using.

Not true

What if you did a piece of metal j channel the foam would sit in like he was talking with the 2x2? Tape it to the surface with zip tape and a bead of liquid flash when installing the j channel. No exposed foam and a nice way to air seal.

@@SnappyWasHere thought along those lines until I heard about Comfortboard. That should be sufficient but haven't run it by any of the bonding guys.

When using zip r do you have to order custom windows and doors? Standard door jamb in exterior on a 2x6 is 6 1/2. So using an Additional 1” that wouldn’t work

Doors: yes, a jamb extension is required.

Flanged windows can be mounted directly to the Zip R (with longer fasteners).

Flangeless windows can be mounted anywhere in the jamb.

I have 1” exterior poly iso on my home built in 1994, I just replaced the windows and am in the process of constructing custom jambs. Replacement windows almost guarantee this even without exterior insulation, so I fully expected it. Not a huge deal, just time consuming.

Come back to Canada (West Coast) and tell us your choice for our cold/WET climate please

IN Vancouver next week!!

Can the foam on the back of the Zip R touch the concrete or would wicking be a concern?

It's hydrophobic

What is a good insulation or product for sound reduction for interior wall cavities? 2 x 4 interior bedroom wall, wall has plumbing for a bathroom on the other side. What can we use to really quiet that wall? I have been told a rock wall insulation because of its density. I don't mind pulling down the rock on one wall That's 12 ft long because I can put the rock back up but I just have to do something about that sound

Check Rockwood, has a sound proofing line too

You’re looking for Rockwool Safe n Sound.

Depending on how far you want to go there are several things you can do. As mentioned already Rockwool in the cavity. You can also use acoustical caulk on the studs before you hang the drywall back up as well as seal around the drywall cavity. You can also do a double layer of drywall on top of all that. The point is to absorb as much of the sound vibration as possible.

Use Resilient Channel on the studs

@@scottv.4140 totally agree with all of this. I probably wouldn't use a double layer of sheetrock, consider going with quiet rock instead, though it is more expensive than just doubling up.

He old to know when Jimmy Carter... Said last oil crunch..turn down your heat and put on a sweater.. 👍

Curious what everyone is doing to mitigate the problem with putting doors and windows in a house with a 2x6 wall and 1 1/2” thick sheathing when door and window manufacturers aside from custom, design their products around a 4 9/16 or 6 9/16 jamb?

Either custom ordered with larger jambs or finish carpenter installs larger ones. I like making them after the window and drywall is installed to they can be made to the exact depth.

I have been installing my own jambs for years....easier to start from scratch then fix what's there.

-Improperly shimmied, if at all.

-spray foam has to be dug out and redone

-fat headers or out of flush framing cause width issues

-drywall cutout bit damage

-drywall mud build up on jambs

-sills bowed up in middle from poor framing, and no easy way to get down/straight.

-better foam job, as the jamb goes in while the foam is still wet.

The cost of the manufacturer's installed jambs vs. Materials and labor is usually an easy sell.

Shim next to window with drywall screws run out to the proper height (a simple jig make this easy).

Spray foam and insert jambs.

Nail adjacent to screw/shims.

Shims/casing to fine tune front of jamb.

This sounds like a lot of steps, but it beats digging out foam and drywall every time.

To fix the fact that you have an extra 1 1/2” foam on the outside, why don’t you have the foundation poured and 1 1/2” bigger all the way around? That way you’re not hanging everything over and you can flush tape if you want. Plus your baring point is not compromised by hanging over the load points. Just wondering if anyone has thought about that and if they did what they had to say about the idea.

So this is just what I have seen Matt do and I’m not a professional so please don’t tail me too bad if I get this wrong…. But I think he does it that way to give the wall a drip edge and so it’s not sitting in water if it were on concrete… he usually seals the “drip edge.” Also I think the wall is bonded to the framing with the fasteners and not so much by sitting on something.

If you used ICF for foundation then you can make the exterior plane of the walls line up with the ICF thickness

set the floor ply on top of the ICF and the ledgers and joists inside the ICF wall, seal under the ply on the concrete and between plates with proper caulking for air barrier. Or better yet just build ICF to the roof, saves so much time

That's exactly what I did.

The concrete forms would be special and HORRIFICALLY EXPENSIVE. = DUMB

@@w8stral

It’s really just a matter of changing a dimension = 💡💡💡

What about shearwall nailing? Like out here in seismic d2?

The kicker is the thermal break to the 2x6. That is going to pay off more than a thicker wall.

How far apart should studs be on a shed wall?

Are there any concerns with perm rating on the zip-r system?

Not if designed appropriately for it

I've seen a lot of your videos. It seems like fire and combustibility isn't a very important issue in USA, regarding the widespread use of plastic insulation combined with OSB? kind regards from Denmark.

"Innovation isn't a product, its a discipline" Nice!

I stole it from a smart client lol