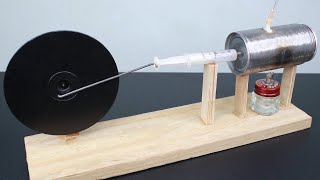

DIY Thermoacoustic Stirling Engine

HTML-код

- Опубликовано: 7 янв 2021

- In today's video I want to show you DIY Thermoacoustic Stirling Engine

TikTok vm.tiktok.com/ZSpFL7GE/

Production Music courtesy of Epidemic Sound www.epidemicsound.com

#engine #Stirling #Thermoacoustic  Наука

Наука

Thank you for this! I'm definitely making myself one!

Did it work?

The issue is scaling it, it loses potential the larger it gets with these it seems. More heat needed and its less effecient the bigger you get. Maybe a 100 or 200 cell large one made of smaller ones could do something but then way to many parts

Orifice tube thermo-acoustic engine, smart and good idea. Needs to assess the thermo-acoustic energy transfer in the presence of this rough orifice:)

Nicely done!

Beautiful work! 🎉🎉👏👏👏👍

Thats what I want 😁💜

Very good your project, simple and fast!

Leandro Wagner.

Can u explain to me something, how the piston come back with the pressure forcing it to go foward

@@flaviomagyar8673 You speak Portuguese? If so, it's easier for me to explain.

@@ManualdoMotorStirling kkkk sim, n sabia q vc era br

@@flaviomagyar8673 Amigo, vou te explicar! Este motor funciona com a diferença de temperatura interna do ar, o pistão inicialmente pressiona o ar quente para lado frio e isso produz vácuo e na metade de seu curso o pistão é sugado pelo vácuo e depois ocorre ciclo inverso.

Eu já fabriquei um motor semelhante a este em um vídeo que postei em 2018.

Mas este motor em especifico do vídeo, não funciona não, isso é fake, primeiro que este modelo de motor com pistão único é muito fraco para rodar esses rolamentos normais que ele usou no vídeo e segundo com a dimensão do motor, jamais iria funcionar usando somente uma única vela como fonte de calor.

Fora outras coisas que reparei no vídeo como o próprio pistão em madeira que não se consegue boa vedação que é necessário para um projeto como este.

Nunca imaginei que um canal com a grandeza como este é, faria um vídeo falso.

Mas tem outro vídeo no YT que também ganhou grandes repercussões e também é 100% falso, lamentável, tudo pela fama.

@@ManualdoMotorStirling também suspeitei que era falso, mas pq achei q ele funcionava de outra forma, vlw pela explicação

Amazing, liked, thanks for sharing 🍀🌈

Good day Sir! A question

How does this thermoacoustic Stirling engine is different from a Beta-Stirling engine?

It's for a project of mine, would appreciate your comments on this

A stirling engine works by expanding when the gas is hot and compressing when the gas is cold.

Traditional Stirling have a displacement piston for moving the air to the cold side before compression and to the hot side before expansion.

This doesn't have a displacer !

So how does it work ?

The key is the steel wool at the end (I think).

It acts as a regenerator. One side is pretty cold, the one near the flame is hot.

So when the piston moves left in compression, the gas moves further into the regenerator and cools down, which aids the compression.

The opposite happens when the piston moves right and the gas expands out of the regenrator. It leaves the hot end and aides the expansion.

But I suspect this is a little finnicky to get to work and the video may be fake.

@@TaserFish-qn2xyi get the concept when piston moves left it is cooling down the regenerator, but im confused on why does it turn left and not just stay at right since the hot air pressure pushes the piston to the right?

@@TaserFish-qn2xyalso, can the syringe tube and piston (corkscrew) parts be replaced with metal? i know that heat will distribute faster but maybe i can create a bridge between the heated parts and the piston using wood or such to establish heat difference, had a school project involving metal and 3d printing and i want to build this

@@artupaysivar6884

A few things make it keep spinning. 1. There is a flywheel/ rotating weight. Even if the hot air pressure keeps pushing to the right, the flywheel still has momentum and squishes the air back together.

2. As hot air gets pushed into the (relatively) colder regenerator, it cools and contracts, effectively "pulling" the piston.

@@artupaysivar6884

Well, it has to run smoothly and be mostly airtight. That's not a easy.

In fact, this whole process quite finnicky.

The size of the hole and amount of steel wool will also likely have to be tuned/ experimented with until it works.

I'm not sure that metal on metal will run smooth enough and with small enough tolerances to make it work. Guess it depends how well it prints.

And the syringe part being metal is really making it harder. The regenerator should be much colder on one side than on the other. If it's all in a metal cylinder, then that doesn't work.

Mayyyyyybe you could make it work but I really don't recommend it. For such a simple project this is more than hard enough to get working without the metal.

You're probably better off doing a typical Stirling engine with two pistons and two cylinders if you're working with metal.

Alpha type for example.

The benefit there is that the hot and cold side are separated.

If it's all in the same metal cylinder it's harder to get a decent temperature difference.

That is if you can actually make the pistons run smoothly and close enough to airtight.

I'm not an expert, but I've wanted to build a Stirling engine for a while and I've got the theoretical background on it.

Lemme know if I can help some more.

Thanks! This is one of the simplest sterling engines out there!

Awesome video

omg yea true bro, very noice

That band saw is totally your second partner 🤘

Watching ❌

Dancing ✅

Nice! You would like to see my homemade 1/5 49cc RC car!

Sor can you pls tell me each materials you used ❤

Fantastic 👀👍

it will work with an screw, that is sanded untlil it fits perfectly, and lubricated with special oil??

good making

So this one has only one piston, Please explain it to me, don't Stirling engines have two pistons, one displacer piston, and one power piston on the cool site? Thanks.

This is what's known as a beta type sterling engine. I don't know much about it myself, but at least you now know the name so you can look it up.

@@lukewest5397 the one with 2 pistons is a sigma??

ruclips.net/video/gQb2sN6UWkA/видео.html this video explains the 3 types od stirling engines

this is a beta type Stirling engine which has one piston and an air displacer in the tube to help cool air, and when the piston moves the displacer also has movement

I think you only need one but it will stall at low rpms

De que medida es el tubo de ensayo????

Buen trabajo

Yo compre uno en tecno_logicos en Bogota (OLX) y funciona perfecto,sin tanto complique

what tape did you use

amazing

What are the materials that were used?

Very good

Good idea, congratulations 👌.

Y isn't the glass breaking Due to tempt?? And what is the purpose of the scrubber

What was the black meterial which was moving front and back

Plz tell

It looks like a graphite rod or something

Exactly it's a graphite of carbon for easy to move.

All that I had to do was turn the sound down (stop the non stop eighth notes), and it is an excellent video.

Thank God someone taught me how to make one. There are ones made of steel with air already in them that can't escape. No mesh needed. How can we make those?

Please let me know what is that black material you used for piston

Great full

Is that a rubber, magnet or a steel?

QUE TAL ME PODRIA DECIR PORQUE PONE LA ESPONJITA METALICA EN EL OTRO EXTREMO?

Why do you need to put that pot scrubber in the tube ? What does it help do

Most likely to help hold a more consistent temperature in the hot side of the chamber

it could be made that the disk is made of copper, that is, make a Faraday disk to generate electrostatic energy and store it in a capacitor, is this possible? can a light bulb be lit?

Are you going to put out instructions? Video is cool and all, but I have no idea how to do the DIY part of this DIY video

Sir pls u can say the material in which black like metal in the video

What is the material the piston is made from? It looks like carbon maybe, but I can't tell in the video. Does anyone know what it is?

Other than that sure seems very elementary to make, and I'm excited as ever to do something like this with my grandkids.

Thank you tons for the inspiration. 😊

korbon çubuk (fırçalı motorlar daki gibi aşınmaya ve ısıya dayanıklı)

incredible, i like that

What's the point of the metal thingy in the end of the tube

What size of tube is that and I’m assuming it’s glass and what type of saw

its quartz or borosilicate glass, normal glass breaks under these conditions.

what the material that you use?

Can someone please tell me what id the radius of the tube

I'm assuming that it won't work with a metal tube?

What kind of experiments can you do on this? For a physics project in school.

Pleace tell me what is the meterial name in block piston

what is that metal that you have cut at 1:01

Is it charcoal?

Can I ask if my tools and materials are needed to make the motor stirling on? I really want to do it

I wish so too

So, in school im making a steam engine in my robotics class, and the steam engine will have a candle in rhe fire box, non flamable material in the firebox surrounding the fire, there will be tubes so the smoke can travel through it into syringes, the syringes control the wheels moving, the smoke will travel from one syringe to another, making the movement, of course a funnel for smoke to escape

Where out put heat was gone?

una pregunta

este motror stirling es tipo alfa?

That kinda reminds me of GNR Stirling Single.

dá hora maninho parabéns

Es una belleza

what is the black thing?

Hey man can i ask whats the size of the test tube?

umm he goes into more detail here, ruclips.net/video/iik25wqIuFo/видео.html

A bit bigger size than the dowel rod he used for the seperator, which was 10mm I think. Then he wrapped what appeared to be adhesive Velcro as a seal, so the tube was perhaps 12mm or 1/2".

I already have it set up, but I can't get it to work

Bro the engine was superb

But what material you used

For the piston head

Please tell me bro

graphite ;)

@@Filippos_77 thanks bro

Hi ,can i ask what is the piston material? Because i didn't figure it out

it is graphite bro

can you put what materials you made from des

Do I need the steel woll

Hi what's that black thing??

Can you make a video of how you make to hide the electric motors (cuz thats hard)?

This video made me realise I have a very dirty mind.

Blueming Brilliant

best video

What are the materials to make it? 😅

steel wool scrubbing pad will corrose with time of use?

Stainless steel scourer was used, rather than plain 'steel wool', which is generally low grade carbon steel wire. Easy to replace nontheless.

the principle of operation is great

I have a feeling that this setup is fake..🤔 In the cylinder there is no enough compression is happening in order to function properly. I think there is a moter attached to the wheel from the behind.(Please correct me if I am wrong)

I am thinking same. It’s isn’t possible work with one cyclinder.

Am s ok glad some real engineers got on here to prove sterling engines are fake!! Next up big earth plot unearthed

@missakalewdeniya1896 you know this the rotation speed of the fly Weel would push the cylinder back in and then the cylinder pushes forward and the cycle repeats!

@@hiddnhitower4620FUCKER IT WAS MADE BY A SCIENTIST BRO WHY DO SCIENTIST THINK ITS FAKE FUCKING IDIOT

Same

I thought yer man's was bout to spark some rocks up

Génial

What is this gray bar? graphite?

yes

Whats used for the gasket and piston?

Glass syring or tube

I got surprised when the one cylinder of my Stirling engine get too much *cold like refrigerator when I have manually spin the flywheel using drill machine .

I could not fully understand it, you can write in Turkish

Yep, reverse Stirling cycle, there is at least one company making stirling refrigerators.

But, how the piston come back to with the pressure forcing it to go foward?

Bro you are right this is fake

Its the flyweel movement that push the piston back to his position , at the same time compresing the hot air that push it back , and thats how works

@@user-xk2hw6ej1z but the wheel dont have enough force to push it back with the air pressing it forward

@@flaviomagyar8673 it does have the force, because the size and weight of it , imagine a real size stirling engine with a flyweel of that size , search Thermoacustic stirling engine , there is another engine like this

@@flaviomagyar8673 yes you right 😌

What's the steel wool for?

To increase the thermal mass.

You cold the Engine With air ?

I have a question what u have used to make piston?

carbon or graphite rod

😊

Did you put metal or Lead in the Tube?

Most likely graphite, extreme heat tolerance and self lubricating so no need for oil

That small piece of Wood where i Can buy it

O:51 what is this black material ??

Do you know it yet?

1:04 what is this black rod?

What is that? In the second 57

What you used for piston

umm some redstone, iron ingot and some wooden planks! OH YEA and the cobble! ur welcome!

Graphite

Materiales??

For a fact, iam actually enjoying the beat of music .

Ye black black kya he 😢

But Stirling engine has 2 pistons so how does this work?

1:01 what is this metal please

What other material can I use to substitute the graphite piston for?

You can use two component epoxy putty to make the piston and then paint it on the outside with a normal graphite lead pencil.

@@PaterCurro is it the stuff you fix pipes with? I'm looking up for a science project and could really use some help lol

@@udaykumartembhare7921 Piston for Stirling made of 2-component epoxy putty, covered with graphite in locksmith powder.

Cylinder is made of pyrex glass, glass syringe, test tube, borosilicate glass, quartz glass, high temperature 400 degrees.

m.ruclips.net/video/OFeIAWIUFP8/видео.html

smallest single stirling

m.ruclips.net/video/b9SXj3RT-eQ/видео.html

a cork

Поршень плотно прилегает?

Или нет?

What material did you use on as piston sir?

It looks like graphite.

Great work, but I was wondering How exactly is this Engine working 🤔🙂.

You're not with a science background, are you?

I remember our teacher told us about this engine back in 11th grade..... It works by expanding and compressing air by heat...

@@animishaalagappa2327 I am from the Science background only, but there is only one Displacer/Power piston in this Stirling engine which makes me Wonder this way.

@@AmazingSciencewithAshishNegi if you don't mind, how old are you??

@@AmazingSciencewithAshishNegi we've had single cylinder engines for a looooooonnng time now.....

@@animishaalagappa2327 allright buddy 👍🙂.

Bro what material is used to make piston

graphite

@@liberman3929 What other material can we use instead of graphite? please reply urgently.

hmm if i made this i could actually make my own locomotive small one actually

Does it works???

How do you Cold the Stirling Engine ?

any