How to Stop Thermal Bridging with TStuds!

HTML-код

- Опубликовано: 7 июн 2024

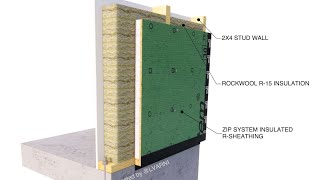

- Wood is a conductor or a thermal bridge. It allows heat to flow easily from the exterior to the interior or vice versa. To solve this problem, a company in the States, called US Engineered Wood, has invented the T-Stud, a framing member that improves the energy efficiency of buildings by acting like a thermal break instead of a thermal bridge.

Link to my Patreon page: / belinda_carr

CHAPTERS

0:00 Introduction

0:47 Dimensions

2:23 Performance

4:55 Ease of use

5:14 Sponsorship

5:52 Price

6:48 Conclusion

MEMBERS

Thermal bridging is the flow of heat by conduction through the studs in a building. Bare Naked T Studs stop the flow of heat because of a gap between the flange and spline. The gap in between is approximately 1.5”. Wooden dowels are installed through one member into the other at opposing angles, forming a web-like pattern.

T Studs can replace most framing members like wall studs, top plates, bottom plates as well as king, jack, and cripple studs. They can be used in either direction. If you need more surface area on the outside to secure sheathing and outside insulation, this surface can face the exterior. If you need more surface area on the inside to secure cabinets and shelves, you can reverse the T stud.

R VALUE

About 25% of a typical wall consists of wood studs which lower the R value of the entire wall. If you use R20 insulation in between the studs, thermal bridging can bring the effective R-value down as low as R15. If you put an R20 batt into a steel stud wall, you may only get an effective R-value of approximately R5. Steel conducts heat much better than wood, hence why shipping containers are terrible insulators. If you use closed cell spray foam in the T stud and R20 insulation in the rest of the wall, the assembly actually acts like an R20 wall, not R10 or R15. T studs allow a 96% complete thermal break through the wall assembly.

MOISTURE

Another issue with traditional wood studs is moisture accumulation or ghosting. Moist, cool air attracts dust and forms dark lines on the ceiling and in closets where a lot of framing gets mashed together. Accumulation of moisture in the wall can lead to the growth of mold and rot which affects indoor air quality and compromises structural integrity. T-Studs act as a thermal break and reduce moisture accumulation in walls.

STRENGTH

T studs are 4 times stronger than traditional studs which fail in the x axis if there's too much of a load on it. T studs don’t behave the same way because they are turned 90 degrees. They don’t deflect or fail in the x axis. While a 2 by 4 can hold 900 pounds and a 2 by 6 stud can hold 2,200 pounds, T studs can hold 8,600 pounds.

INSTALLATION

Installing T studs is very similar to nailing traditional studs so there is a minimal learning curve associated with it. One thing that’s different is the fastening of T studs to the ground. Instead of just a threaded J bolt or lag bolt, you need a wide plate that straddles the two wood studs and transfers its hold down power.

COST

T studs are obviously more expensive than traditional studs but their increased cost is offset in a couple of ways. The first is waste. About 5% of traditional studs are usually too warped and damaged to be used. On the other hand, less than 1% of T studs are unusable. The second is reducing the number of studs needed. These can be spaced 24” on center instead of 16” on center. The third is the reduced weight. T studs are lighter than traditional studs, which lowers the cost of other framing members and even the foundation. The last point is the lower energy consumption of your HVAC system and other appliances. By eliminating the thermal bridge in your walls, the interior space is essentially unaffected by the temperature outside. T studs can help lower your energy consumption and carbon footprint.

The one downside I can think of is that it takes up more interior space because it’s as deep as a 2 by 6. It may not be a viable alternative in tight enclosures when every square foot counts. It’s also not going to be used for interior studs because it’s more expensive and because thermal bridging is not an issue inside. T studs can raise awareness of the problem of thermal bridging and the need to address it.

--------------------

SOURCES:

• Insulated Studs? This ...

--------------------

Fluffy by Smith The Mister smiththemister.bandcamp.com

Smith The Mister bit.ly/Smith-The-Mister-YT

Free Download / Stream: bit.ly/stm-fluffy

Music promoted by Audio Library • Fluffy - Smith The Mis...

---------------------

Disclaimer: This video was created for educational/informational purposes and qualifies as Fair Use. If you are the creator or own the footage featured in this video and have reservations please notify me via RUclips comments or email and I will accommodate you

#stud #construction #innovation #architecture #buildingscience  Наука

Наука

I'm building right now with the 2x8 T-Stud, love the product for so many reasons. Utilities are so easy to run, the studs are so much easier to move/hold. All 52 of my studs ordered are true and straight.

@@AdamA-pm3yn ruclips.net/video/NNZUfV7yFVc/видео.html

Would you share with me how you did your top and bottom plates? Did you use the tstud for those or did you go the traditional route and only used the tstuds as your primary studs?

@@patewok3649 I did traditional double top and double bottom, this is for my garage so I wanted to get to an 11 foot wall (6 inches exposed concrete, 6 inches top/bottom plates, and 10 foot studs) so I could get a 10 foot garage door. I didn’t do the top and bottom plate using the tstud and I’m not sure if I will or won’t.

My first thought was "cool", then the second one was "how much". With material prices through the roof (excuse the pun), designers will gravitate to the lower cost alternatives to stay on budget.

@Chuck Stark the t-studs with "Smart framing" is probably the best way to go.

Would really have like to seen:

1) Actual cost per lineal foot, or the cost of 1 standard stud vs 1 t-stud. ("General concept" costs are useless).

2) Seen the studs actually connected at the base plate and top plate.

3) A discussion about standard stud lenghts. How easy are these to "cut to size"? Can you order them to a specific length? What happens if the top of your wall slopes? Etc...

It is roughly $2.50 U.S. per board foot compared to $0.50 for traditional studs.

Matt Risinger did a video on these on his channel a couple of years ago. It's been a while since I watched it but I think he had more detailed cost information, and he defeinately had more construction details (he visited a house whcih was being built with them)

@@andrewalexander9492 Funny, that's the first video I watched after this. It was way more informative.

@@thomasstuart2936 Dammmmm, that is way more expensive. Maybe for rich people's high end homes, but I can't see a 100 unit apartment building being able to swallow that price bump...

Pleeeese bro like any of that matters when building your enemy's house

Wow!!, dear Belinda Carr, what do you provide a thorough and wonderfull clear contribution to me as a builder in the Netherlands. No other company or organisation has shown such thoroughness and clear speech on all these matters. Thank you so much. Keep up your wonderfull work.

Sincerely yours, Ernst Klijzing, Amsterdam, the Netherlands.

I have just discovered your channel and have spent an enjoyable 1½ hours watching your videos.

The problem is I only meant to spend 10-15 minutes watching RUclips!

I find your videos professionally produced, enjoyable, with just the right balance of technical information and length of videos.

Thank you for your time and effort that you have so obviously put into your work.

Ha! 2:42 Belinda got another crack at shipping containers. Love it!

T-studs are basically a simplified Larsen truss system and is very similar to a double stud wall. Even 2x4's can be spaced 24in on center but when you do you reduce wall racking strength. This makes it weaker in storms ,seismic activity and more sensitive to termite damage based failure. If you run wires into the spaces then insulate future upgrades and repairs become almost impossible without costly measures. If I were building a super insulated house i would use double stud walls framed with 2x4's 16oc. this gives about an r45 from the wall and r3 from zip-r sheathing for a combo of r48 at less than half the cost of 24 oc t-studs since they cost more than 5 times as much as 2x6's let alone 2x4s . When they become cheaper maybe but at the old methods stay true for a reason and that's versatility .

@@AdamA-pm3yn There is probably a million ways to do it ,I was giving a better example than the option provided . It's not just for cost but im sure those things are not code legal everywhere.

@@wind5250 Indeed,there are....maybe you guys should leave the ,,american way'' and,,we are the best'' slogans,open the eyes and look around the world how others build their homes.I promise you gonna be surprised. From my european perspective,a wood building i would call it garden shed,not house.

@@draculakickyourass I don't just comment i'm a licensed and certified residential building contractor. I am well versed in home building in wood , concrete ,brick,stone, steel and more. Your comment makes virtually no sense because the materials used to construct buildings and homes are those in abundance to the area they are built in.

The idea Your building methods would not only work here but be superior is completly laughable. We neither build for the same enviorment or set of requirments.

@@wind5250 My idea is not laughable,,but yours about,,environment'' Do you live on another planet? Same soil,same gravity,same range of temperature and humidity. The house my parents built in the 60 endured 5 big earthquicks from 6 to 7.6 Richter, cold winters like in Alaska and summers like in Florida.It is built with BCA blocks.If i would sell it tomorow,the price would be at around 80% of a new one,because are built to last centuries. Can you say the same about the garden sheds you build from couple of sticks and boards? No,they will be garbage in 50 years,but somehow in a misterious way your methods are always superior....

@@draculakickyourass You're either a troll or just a moron. Environment : the surroundings or conditions in which a person, animal, or plant lives or operates. What you described is climate or weather LOL. The price you build or sell a home for has nothing to do with longivity or it's selling price that's dictacted by the area and currentt market.

You should study and learn more before you talk. Just by typing in google"what building material survives earthquakes better" You would learn it's wood and steel not stone. The three most earthquake prone countries on earth all have most of thier homes made of timber. You can check yourself , the list is japan, canada and indonesia . Why? Because the environment called for it.

Fyi . Fifty years isn't even a long time to brag about a builing since trailer homes are built to last 55 years. A simple google search further prooves your stupidty showing the Horyuji Temple in japan having stood for over 1300 years and it's built out of wood.

Thank you for this video. A very good introduction to T Studs. I am designing a new house using them for three reasons that you mentioned: a) thermal break b) strength c) internal routing space. We are combining T Studs with Z R-Sheathing. The internal routing space was a big plus due to the amount of wiring being installed. We are also expecting better external sound reduction.

We've solved the issue of thermal bridging in Northern Ontario where every residential house has to have a 2" styrofoam insulation (continuous) on the outside from below the frost line all the way to the eave.

Do not us styrofoam XPS please. The off gassing is 1200 times worse than CO2 for Global warming.

There are better alternatives such as Roxul mineral wool warm board or HALO Graphite EPS. XPS is the worst

There is a similar requirement in Australia (min 12mm foam strips or 20mm thick timber strips), but only applicable to steel framing with a lightweight cladding. (i am honestly surprised it hasn't been increased to cover timber framing and all claddings)

does that not create a vapor barrier on outsode wall creating a moisture trap for wall rott

I think the best way to wrap a house is two layers of 1+1/2" Roxul warm board, staggared butt joints from the eaves to the footings. 1X4's structurally screwed onto the framing to hold the exterior house wrap, insulation and provide a base for siding

@@trtinda11 yes i likely does (I'd missed the word continuous in MbR's comment), our building code stipulates a thermal break to the metal framing to be at minimum akin to the right hand shown image @ 7.21 plus other considerations and manufacturers specs for vapour permeable membranes etc to reduce moisture accumulation

I remember seeing these when Matt Risinger did a video on them a year or two ago. An awesome product I hope takes off in my opinion.

Honestly I love this content. All of your videos are to the point and factual. I look forward to your future on here.

Belinda, love your videos, one of the best channels on RUclips! Thank you!

Thank You, Belinda! Very well explained....as usual!

Thanks for bringing best stuff!! This is my go to channel for housing.

That's a very interesting concept. Thanks for the video. Your presentation style is very impressive; clear, concise and informative.

Passion for teaching, great pedagogics! Thnk you Belinda 4 your excellent videos

This was a great video with a lot of valuable information, thank you!

Excellent delivery!

Continuous learning factor going on here!! hmmm t-studs; thanks for the introduction!

This is a promising product, thanks Belinda.

The algorithm removed my subscription to your Channel a few months ago. I'm glad to see you're still doing videos and I always learn something out of your content. Keep up the good work Belinda!

Been watching Matt’s channel a while and first learned about t-studs from him, but love the details you added.

Not even a constructor but as well impressed how good you laid the topic out. And english is perfecttttttt. Both thumbs up!

This was a great video! I didn't know about this issue. Thank you for this content. I look forward to watching more.

Awesome! Glad to finally see you cover these.

When I first learned of this product (which was awhile ago) it was very new.. they were still getting logistics

& manufacturing hammered out.

I think it's an amazing product as far as concept goes. There is no place to order them from locally. I contacted my

local lumber yard to tell them what an amazing product I thought it was.. & that's about as far as that got.

I, too, heard about them a while back and was interested right away. But they didn't seem to be available.

we appreciate your support! We're working on gathering independent distributors to increase availability. We do direct ship now though if you're still interested. We've also had other split a truck as well to combat shipping costs.

You are a smart, cool lady. Your take on Containers used as houses was an eyeopener. 10-thumps up.

Wow. You are great. Your video gets right to work and provides information EXACTLY as to what is titled. Very refreshing. Thanks.

Good video, but I missed the "Price" section of the video.

I asked them but they wouldn't disclose it. It's about the same price as an LVL.

THIS CHANNEL IS GOLD

Thanks Belinda, great option to consider

My name is Thad but the ladies call me T-Stud so I approve of this product.

Nice job Belinda...as usual.

Wow, what a great idea. Great video! Thank you

Excellent video! Thank you for the information!

This is the first time I visited your channel And I'm very impressed. all the options of the t-stud are very valuable in building. Whenever I used two-by-fours they were sometimes too heavy because of moisture. I hope they use them in modular homes.

I love your videos

Always Straight to the point

Looks like the product has evolved a bit since the Matt article ("T" vs "I"). The vertical loading info is a real plus as is the services passing. Price comparison for a basic 150mm/6" wall would be interesting esp. given the larger stud spacing potential; more expensive I'm sure but you do get that reduced thermal bridging. Great article, thanks!

This video was great! T studs is an investment I’m definitely going to look into when the time comes

Super interesting method. I've never seen or heard of these before

Living in a rural area, I discovered other roles that traditional studs play. My house is built with 2x4 studs, but with 1” foil-faced rigid foam panels between the studs and the drywall. When a mouse manages to get in to the wall, it can now chew highways from stud bay to stud bay by chewing through the foam. And as a volunteer firefighter, I learned the important role that studs play in limiting lateral fire spread along a wall.

I love the idea of a stronger, more energy-efficient stud, but it it brings with it added fire danger and the ability for pests to freely move within the walls, I’m not sure I’d go for it.

If I were marketing something, you would be my first pick to inform people about it.

You are so facinating. I love learning from you

Excellent presentation

great job Bellinda ... I really appreciate your fair and professionnal product recommendation. I specially appreciated your critical but fair evaluation about 3D house printing. I share 100% you evaluation // best Alain from Paris France :😉)

Professional as always.

This is awesome, and a super great idea.

I’ve been a big fan of these tstuds for a while,

And as far as the “loss of space” goes its 2 inches, thats barely noticeable imho and this is only for outside walls.

What you will notice is much lower amount of sound from the outside, perfectly straight walls, (especially key for installing kitchen cabinstry)

better thermal insulation. And framing 24 inches on center instead of 16 due to the increased strength, saving costs in material and labour and again even less bridging should mitigate the extra costs pretty well.

24" on center? You might as well said 24 miles on center. Everyone knows that studs 16" on center keeps bad guys who are fat out of your house. But 24 " on center?? Are you essing me??

I'd be yelling HEY GRANDMA COME ON OVER! DONT BOTHER KNOCKING JUST WALK RIGHT IN THROUGH THE WALL OUR STUDS ARE 24" ON CENTER!!!" She'd probably gasp and her face flush red at my basically announcing to the whole neighborhood my stud to wall ratio and the space therein between each wood support!She would probably stay home with her shades tightly drawn based on principle alone! 24" on center how effing embarrassing man!

@@Blake4625kHz you’re worried that people instead of breaking your window are going to come in through your walls??…

Also one of the best ways to build timber frame is like 5 yards on center the whole reason you have so many studs is because all the studs are weak.

if you have a couple really strong studs say 2x8 or tstud, the final structure is actually way stronger and easier to build around and better insulated.

There’s literally no downside to going to 24 inches on center if you’re strong enough like the tstuds are.

Look at their strength rating it’s almost 10 times as strong as a normal 2 x 4, and using 50% less so overall your structure is like 5-6 times stronger

@@FreekHoekstra

I say! Good lord man! Do you kiss your mother with this same kind of mouth? So many factoids you have. Clearly, you not only shine your own shoes but WEAR THEM TOO!

Apparently the facts do not care about my feelings! You seem an apple pie times radius squared kinda guy.

Cheers Maverick 💥

@@FreekHoekstra there is one downside. when you're trying to find a stud to drill into, there are less options. only one I can think of

@@V.Hansen. fair, ou could adress with blocking, but yes thats a fair point!

Love you Belinda

Great video! Thanks

Great information!

I saw this on another channel, before they moved production to the US. I like this concept.

I love your channel and the information you share. I trust your honesty and the knowledge you've acquired. Could you do a video on types of cladding for exteriors for new and existing structures, and if there are any better, newer alternatives to aluminum and vinyl siding (preferably something environmentally friendly and/or more protective for the structure underneath)?

Thank you, either way.

I've been aware of the Tstud product for a couple of years now and I believe its a great product for all of the reasons you mentioned. The fact that it eventually pays for itself is just a bonus. I was wondering why the pre-insulated Tstud was no longer available. Thanks for answering that question.

Hmmm... interesting.

Very well presented.

Cheers.

Excellent idea

Love this idea, and one that seems long overdue.

Awesome product!!

Those are really nice. I like that. I'd buy them just for the ease of running wires and pipes. Then add in thermal bridging, the resistance to buckling... these are a really great idea.

Also I love the low key dig at shipping containers. I actually wanted to buy a few shipping containers until I saw that video.

Very interesting. I need to see how the local building code looks at the use of this product. Thank you for sharing this information.

Good for you. Great channel

Over the years I have done allot of different wall types. Everything from traditional walls with studs to stagger stud walls for theaters and recording studios. I had seen some promotional videos on them some years back when they were first coming on the market. For the home exterior wall the T-Stud appears to have the edge on overall long term cost when taking all the factors into account such as cost, labor, and energy savings over time. They are a serious consideration for our upcoming build and the most likely choice.

Seeing this makes me sad, 35 years ago my Dad and I built 3 houses built with Therosteel. A galvanized steel product developed and patented in Canada as a franchise. So we invested and the products were amazing. Tubed metal welded to C-channels to make the outside studs, this was both very strong and prevented heat transfer from outside to inside. All houses are still standing, no sags, no cracks and walls are still straight. Fire insurance was ridiculously low as all materials used were fire resistant. Metal roof, walls, stucco and brick outside. But the company went under and the like of it I have yet to see again. Bummer. We had a dozen or so interior studs and few exterior ones left over. Still sitting outside in rain and sun and in good condition after 35 years. That is what is needed again. The low cost of insurance and minimal maintenance have paid for extra cost of materials and is now saving money for owners, but we don't build to save for future, we build to make biggest profit NOW who cares if house burns down in a few years.

As great as this product is, it might end up like the one you described.

Let us hope that these inovations can catch on. And the one you describe can come back.

Without this You Tube channel, people would never know about either of these products. This woman is doing very important work.

Any chance you could write a Wikipedia article about Therosteel?

The product sounds great, do you have a picture of it? I'm having a bit difficulty visualizing it.

I want to learn about this Therosteel that you mentioned.

Framed with wood for the last 50 years...as it was always the cheapest. Am now building with concrete block and CFS joists, B-deck, rigid insulation and roof board....amazingly, this system is now cheaper than wood with better longevity, fire resistance and insulation qualities.

Simple design with a much better insulation value, very clever!

Very informative!

Great Video

I had this idea years ago, but never pursued it because I thought it would be too expensive and that it would be so overly involved in its manufacture that it would be too hard to get off the ground. I wanted to use bamboo for the dowels because it's so strong for its weight and size, and the best I could come up with was a pre-sized stranded dowel and a jig for drilling and gluing to sell as a kit for making these on-site as needed. I'm sure you can guess how hard I'm kicking myself right now. >_<

I knew it would be stronger and better than drilling through studs for pipes and electric, but, based on your numbers, it's even stronger than I estimated it would be.

it is still too expensive, average t-Stud 2x6 is $2.50 per linear foot or $20 for an 8 footer. This is $12-15 more than a normal 2x6 stud, at which rate ranges from $4200 to $5200 more on an average house. This cost could have been used for Zip Board with Polystyrene underneath giving R-value along with the thermal barrier for the same price.

Adding the strip of insulation sounds like a neat idea.

Great information, is there any acoustic benefits ie does it help keep an area quiet?

Solid video

Well ok - I would like to give a few comments: In general wood is not considered as a cold bridge, because of the insulation value of wood. But yes of course - it is still a great idea to break the massive wood in this or other ways - there are other ways to do it as well. I "invented" another method at a factory I worked at back then, appr. 12 years ago. I have seen another variant of these studs, where both flanges are oriented the same way. And I think they just used wood dowels for the spacers. But to turn the one flange 90 degrees to form a T-stud is actually a great idea. These kinds of open studs are very well suited for blown in insulation like wood fiber insulation. Also because of the demand of increasing insulation thickness, to decrease the energy consumption of the house, this is a great idea, because they can increase the dimension of the stud, but still use the same amount of wood in the stud - just longer spacers. All in all, nice video and very interesting - and an interesting topic.

I just did the structural engineering for a house using 6” Tstuds. At first I was dubious, but once I found stamped technical literature quantifying their structural properties, I felt reasonably comfortable using them. To minimize the carbon footprint, we’ll be insulating these walls with wool and avoiding spray foam.

Well done

As always, nicely researched and presented. As to the secret dowels, if they are not composite materials they are most likely a hardwood of some description. I wonder if the building codes treat these studs as a legal alternative to standard framing? Thanks for sharing this great content.

Excellent video. How does one stop ghosting if one cannot rebuild the walls?

Thanks

Here in Ontario Canada the traditional solid stud forms a very important function besides being a structural item. It is a FIRE STOP.

If you use T studs with spray foam insulation in the wall void, the entire exterior wall assembly has no fire stops. As such it would not comply with the Ontario Building Code. You would need to add some fire stops to compartmentalize the exterior wall to prevent fire from easily spreading horizontally through the wall (left or right).

I'll stay with my proven exterior wall assembly.. 1/2" gypsum board, 6mil poly A/V barrier, 2x6 wd studs @ 16" oc, roxul insul R24, 1/2" OSB sheathing, 1.5" IKO Enerair LTTR R8.5 continuous insulation, 1/2" plywood sheathing, BlueSkin VP air/moisture barrier, cladding system or masonry veneer.

Great for new construction

Her point about running utilities through them seems a lot more useful to me, since you can screw thin wood to the studs through external foam insulation to combat the thermal bridging

I think they are a neat idea and definitely better that traditional studs but I still like continuous exterior insulation much better.

Thank you.

Great product. You forgot to mention the savings on the electrical and plumbing trades rough-ins.

Wet interesting. Thank you

I'll be utilizing these for my last custom built house. Pricing is 12%+ more than conventional framing but you get all back and then some with the savings from your heating/cooling costs. And the fact that it has so much more load bearing qualities; this is a no brainer. Houses built today are not made to last more than 40-50 years without having a major renovation. My next house will last a century plus.

On new construction, it seems like it would make more sense to spend the money on exterior insulation that you mentioned.

You are a great salesperson

Pretty interesting 🤓

I'm looking for a best material suggestion: planning on building a collection of single pitch sheds as a not so tiny home. What I'm looking for is what to use as as a continuous sealed exterior sheath over the fraiming, and covered with corrugated metal.

jerryrigger, you may want to consider ZIP System R Sheathing.

Question: at 7:23 you mention "strips of insulation" on wood studs to create thermal breaks. I am trying to find some to purchase but not having any luck. Could you please provide search terms or product links? Thank you in advance.

That is actually pretty smart, resembleshow we build brick walls here with a small thin bridge between the outer and inner wall to minimise heat loss

Any data on reduction of noise transmission? Might be useful also for construction around airports, freeways, etc.

Thank you

If one is going through the extra expense of T studs they shound also come in an eight inch or greater widths. As a Canadian home builder I find R20 insulation and double pane windows inadequate for modern energy efficient housing.

Dense pack cellulose would save using copious cans of spray foam to fill the hollow cores. Store carbon and reduce landfill at the same time.

The extra load bearing capacity may reduce the need for built up load bearing points in some cases.

They have 2x8 equivalent studs so with rockwool, that would make it an R30 wall.

Looks like an interesting product I never know existed.

The beautiful Belinda

Good stuff

Nice! TY! 1/3 less material for outside walls, 4x stronger+, reducing heating cooling bill, reduces cost of insulation goals.

And roughly 5x the framing price. Not to mention the general lack of availability. I'm not knocking T-studs... but there are trade-offs.

@@floobertuber GREAT point, TY!

Curious how effective that strip on insulation on a standard 2x4 or 2x6 stud compares. That certainly seems like an extremely simply solution that would be a minimal cost.

Definitely an interesting product that hopefully more home-builders will use for their exterior framing! The manufacturer's logo is a bit confusing in its identity... "US" with a small red maple leaf, making it convey that it's a US company, but possibly Canadian as well?! The product definitely makes sense for construction across Canada. I wonder if the reduced density of a palette of studs also adds to the cost of storage/shipping...

Too costly in 2022

Looks like an amazing product substitution for the traditional studs.

Awesome!

does it also make a difference with sound conducting? so interesting

In UK Europe, i stud walls are used, the same as the I joists. Only a 10mm flange. Much easier to ensure insulation tight to the flange.