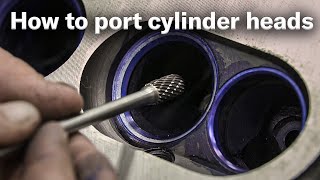

LOW BUCK, DIY HOME PORTING 3800 L67 CYLINDER HEADS-DOES IT WORK? I TRIED HEAD PORTING-DID IT WORK?

HTML-код

- Опубликовано: 9 фев 2025

- HOW TO SUCCEED YOUR VERY FIRST TIME PORTING HEADS. CAN YOU REALLY PORT YOUR OWN HEADS. WILL YOU RUIN THEM? DON'T BE AFRAID, WITH BASIC TOOLS (FROM A PLACE LIKE SUMMIT RACING) JUST A LITTLE COMMON SENSE AND AND CAN-DO ATTITUDE, YOU WILL REALIZE IMPRESSIVE FLOW GAINS. CHECK OUT THIS VIDEO WHERE I PORTED 3800 SERIES 2 L67 HEADS FOR THE SUPERCHARGED V6. LIKE YOU, I HAD NEVER PORTED A SET OF IRON HEADS, NOR DID I HAVE AND EXPERIENCE WITH THESE 3800 HEADS. BY UNSHROUDING THE VALVES, BLENDING THE BOWLS INTO THE SEATS AND MAKING THE SHORT TURN RADIUS SMOOTH, I WAS ABLE TO GET SOME PRETTY DECENT FLOW GAINS (SPENT LESS THAN 45 MINUTES TOTAL ONE INTAKE, EXHAUST AND CHAMBER).

![Seungmin "그렇게, 천천히, 우리(As we are)" | [Stray Kids : SKZ-PLAYER]](http://i.ytimg.com/vi/kAzmhLHePqU/mqdefault.jpg)

OK... as Dyno Dude Disciples (DDD) and members of Citizens United for Performance (CUP), known collectively as DDD Cup, we recognize that Tricky Ricky has tip-toed into the world of iron head porting. He has achieved a rank of NOVICE on this day, Thursday November 18, 2021.

I strut!

You're a brave man showing home porting with all the internet experts ready to pounce. I really enjoy most of your videos.

Richard has become my go to

to escape from difficult people

It would have been interesting to see a before and after dyno test with those heads, to see just how much power the flow gain would equate to

Rule of thumb is 20 CFM increase in airflow = 20 hp for a 4 cyl. engine => 30 hp for a 6 cyl. engine.

Fantastic example of just how much work goes into doing heads, should give people who complain about the price of properly worked heads an appreciation of the skill and time involved in making even std heads better never mind full race porting.

That argument hold water until you take cnc heads into account

Absolutely badass video. I sent the heads you sold me to Bigdogs Porting for Porting & bigger valves. I can't wait for the results.. I'm very excited to see the difference

Well done man. It's great when a non head porter earns his iron spurs.Yeahhhh! 13 percent increase in flow everywhere will eventually increase power and torque everywhere.

Great video, good to see more hands on stuff that any Joe Blow can duplicate to make more power.

Don't get me wrong, I still love seeing the testing but it's good to see a how to video in the mix.

I thought I was the only guy to use a drill to lap valves. Good video.

This is an awesome demonstration with actual results. Love the effort that goes into all this, thank you for doing and documenting this for the rest of us

I've got to get myself a spare set of heads now. I am porting out my aussie m90 at the moment so while I'm in the mood for porting I might as well keep going.... thanks for being an inspiration to all us junk lovers

Have fun-THE PORTING WILL DEFINITELY HELP

I know you love these 3800s, and I know you love upgrades for junkyard stuff, so I figured I'd tell you about something cool I found 👍 I found a company named "Magnum Powers" that makes an upgraded cases for the Eaton M90 blowers. Aside from stronger material they claim it has longer intake and exit port duration that allows it to he spun considerably faster than a ported M90 without excessive heat soak. It's a bit pricey but if it works as well as they claim might be worth it 🤷♂️

back cutting the intake valves can get big gains also, 35yrs ago we saw a huge improvement on some heads by going to a tulip shaped exhaust valve!

Ritchie I love the videos and you're excitment to tear into any engine right now I'm into a teardown of a 2000 lm7 and have been watching everything you post keep it coming thanks so much for the speed secrets lol God Bless You

Nice work Richard! I didn't realize a guy could get 25 cfm with just a little bit of grinding 😳You have proof though, I seen it! haha. I did this on my LB7 Duramax on my channel (heads, exhaust manifolds, up pipes, down pipe and turbo) and it was 100% worth it. It was a bit intimidating at first because it was also my first time and those heads are expensive to place. But no guts no glory eh? Cheers to learning new things 🍻 and thank you for all the content!

Right on

Now your spreading the mustard.

I have ported many, many sets of factory SBC heads. Majority for dirt track racing. You are so true about the first 20 and I would even extend that comment out to the first 40 cfm for those gearheads that are hands on kind of folks. Before I stopped building engines I was overly impressed with the vortec heads except when I found the thin areas.

One thing i learned porting rotary motors is, when you first getting started, do not do a complete port at once.

What i mean is, do your unshrouding on all the chambers, then do your chamber blending on all the ports and so on. Do all the intakes then all the exausts.

The point is, divide your work into small operations, and do them all across the head. It will help you with consistency.

If its your first time with the grinder or with”this” cutter, start with the gasket match. Away from the valve seat, until tou get the hang of it.

If you are afraid of nicking your valve seats, nali polish. You can build it up a bit so you can have an extra .00000001” before you ruin your valve job.

Take your time, and don’t get greedy. Bigger is not always better.

And if you have the means, go to a junk yard and buy a head. Usually they have cores”bad heads that were returned” that you can buy for scrap price. You can practice, then take them back and sell them for scrap.

Totally agree. It is so easy to forget what you have done in the other holes when you try to do it all at once. You should look at it like six sandwiches that you want to eat. Take a nibble go to the next one and just keep going around and around till all six are gone. It is the only way to ensure constancy between them all. Keep referring back to the other ones. With core shift you may need to remove less from one area than another (or not touch the area at all) only little nibbles and focusing on the shape will you spot what needs to be touched and what needs to be left alone. Also do the most prone to damage areas last. Starting with trying to go out to the gasket first up, doesn't leave room for errors should the cutter slip while doing another area, or the grinder chuck nut try to take a bite out of it (focusing on the cutter and not paying attention to the grinder itself) , then you have a gouge outside of the mark leading to a cylinder leak.

Those are some awesome gains! Definitely going to look at unshrouding my valves if my heads ever come back off. I did the ports but was nervous about getting close to the valve seat

Did the same thing with my Aveo head. Th factory head was terrible on the bowls. I ran good with not effecting the gas mileage.

Well worth the effort for any normal person to do a cleanup port job like this. If your worried about hogging it out too far just pickup a junkyard head of the same casting and go to town with a drill bit, heck, cut in half to really get a good look.

I had a set of heads for my L67 done years back with minor porting. My machinist did a 3 angle valve job and moved the seat to the outer diameter of the valve and cut a 15 degree angle in the seat to increase the diameter through the seat. Never flow benched but cool to see what it likely made.

1000th like! Huge thanks for putting this up with not only the results but the journey and workings of how you got there. Cheers from downunda mate!

Pretty good improvement for a beginner I’d say. Super handy to have a flow bench to check work as you go

You increased flow 10% and better at all lifts on both intake and exhaust. In theory if intake and exhaust allow it a 200hp motor should see 20 more hp. Nice for so little a change.

I wish it was that easy!

got some 5.7 vortec heads. want to do the same. just gun shy. don't want to ruin the heads. outstanding job.

I ported the heads on a 3800 top swap build. I'm sure there was improvement in efficiency, but I kinda wish I had done a before and after with them. Or at least get to see some actual before and after dyno tests with ported heads.

Outstanding content . 3800 is/was an underutilized platform that powered Grandma's C&H bodies and kicked ass in G bodies . I always thought the 3800 would have been great in a S truck . I cringed when you lapped the valves but not being critical .

Why the cringe?

Hey, this looks like a UTG porting job. Cleanup, blend and go. Best bang for buck!!!! 👍

I ported the heads and intake manifold on my boosted LT1. I have zero data to compare before and after, but it took hours and left quite a mess. If anything, they're lighter than they were before haha.

🤣🤣 goals man. I think pushing yourself put of your norm is what makes you get better. Do you man!

Boy I sure don't miss scraping off old non-metal headgaskets. I feel for you Richard, especially having to use the Cali compliant solvents (which don't seem to solve anything).

Razor Blade rebuild

You should try porting your 8.1l heads. I just did mine. Just keep to the combustion side of the throat while straight line eyeballing the valve guide to start. If one goes slow and stops when the throat just starts to exceed the valve your gold. Also the exhaust guide boss has a ton excess between the combustion wall and the guide if one really wants to dig it out, more power!

airflow data?

@@richardholdener1727 I wish, no flow bench. There's a guy on here that got 315 cfm with plenty of meat on the bone so to say. Pointers...use stone NOT carbide, stone makes powder carbide makes slivers. (I think that's where the crack LT's ugly truck head began, never heard of that before but it fits better then heat causing cracks rather then warps.) I digress, another tip is the valve seat cut marks. People whom have never seem valve seats installed, wrongly think this is a 4 angle valve job. When the hole for the seat is cut into the head a perfect cylinder shaped hole is made with a drill press, a valve seat is pressed in and cut. There is however leftover of that cylinder shaped hole above the valve seat, this is a flow restriction and in no way a valve seat or it would follow the circumference of the valve rather then the hill of the combustion bowl. There are two other valve angles to KEEP AWAY FROM they reside on either side of the cut seat and help air around the valve. The throat of the exhaust valve boss has like a full centimeter on the inboard side, a talented hand could possibly match the intake and exhaust boss shape...it will be getting thin at that point though. Which brings me full circle to stone over carbide, with stone one can actually hear the thickness of the metal in the tone. Also try a electric rotary tool with a foot pedal, they work like a sewing machine much more instant control, makes going slow easier.

As a question do you think .57 lift would clear stock 8.1l pistons? That's only like .026 bigger then the zz502, not much. Raylar says his 202 is based off the zz502 and that his 203 is bigger. Do you think a comp cams matha thumper would clear?

OK so I've been done with my 8.1L heads for over a week. Can't seem to find a flow bench in maine....help! I CAN drive to NH but that's time and gas. I simply can't believe there is no flow bench in maine. If you have one, and be willing to set up a day...I would love to reassemble my truck, I would also appreciate better eyes then mine inspecting my work before just turning over the block on them.

As an aside, on the intake, the runners can shave 4mm off casting over-squish, and extending the oil drain tub on the bottom with a 4in tube the full length has more surface area and air speed then removing the tub and replacing it with a flat sheet simply lowering the entire floor 1 inch. Either way can someone help me find a local flow bench and I'll discuss my 8.1l porting method, as it should flow WAY better.

Thanks, Richard!

At 17:40 the "Super Richie Port Job" is converted to "Super Richie pork chop" in closed captions

THOSE R GOOD TOO

You got 10% plus.... is that right? Not bad for a rookie... "Grasshopper, seek first to know your own journeys beginning and end...But in this seeking, know patience." [You shall succeed] - Master Po.

Looking at the vid on my laptop (as opposed to smart phone), we can see you removed very little material - BUT, you got 10% or so. I'll bet a little more aggressive work could get you another 5% - streamline the valve guide bosses, smooth out short side radii a little more, and fine tune the intake/exhaust port matching. Really cool gains nonetheless. Great before and after comparison.

there is an easy 15 cfm left in more work that I could do (plus valve job and bigger vales-the BOMB-it flows 300 cfm)

I want to see what Eric Weingartner could do with a set of 3800 heads.

ME TOO

area on spark plug boss at bottom of chamber leg or lip toward intake side and protrusion into exhaust port smooth and blend bet worth 6cfm.

I did the spark plug boss near the intake

Iron heads take awhile to port. But on the plus side, they're "newbie friendly". Less risk of accidental damage.

It's always funny when I see someone I know from other places in my feed.

Are you still modding your Fiero?

I sold the Fiero awhile back... replaced it with a 3-series BMW.

Thank you Richard!

Awesone vid Richard!! Please keep going on them !! We need dyno results !! 🍻

I had to do the head gaskets on my mom's car with the NA 3800 and figured I needed to lap the valves and it was the first time I have ever done it and those iron heads sucked

The stock numbers are on point with your numbers on the 5.0 Gt40p heads..... 🤯

Goes to show you how neutered the Ford 5.0 has been all along

184 .500 185

173 .400 183

153 .300 158

112 .200 118

057 .100 054

3800 vs Gt40p stock intake port flows

154 .500 125

148 .400 123

130 .300 115

099 .200 093

048 .100 046

Exhaust flow

The exhaust flow is embarrassing on the gt40p in comparison 😭😭😭

Richard, I thoroughly enjoy your content but these L67 3.8 videos are super interesting to me because it’s different and I own one. I hope you keep going with this engine platform. It’d be great to eventually see you put some good rods and pistons and really hit it with some boost. Find out what the block, crank, and head gaskets can hold.

Have you looked at street machine carnage channel? The supermang project is building a pretty stout l67.

@@guyharrison909 I’ll check that out.

Supermang is an absolute nugget.

King of mang is where its at (look up 1000hp ecotec) (fullboost channel)

Iron is easier to work with and good practice to start... I used several types of grinders with an angled grinder for smoothing inside the bowl and areas as I find I can see the areas better looking down the tool from the top. Also higher speed tools and correct bits can remove the material quick with Aluminum and Iron being more forgiving of mistakes. And starting with this video and many others around, any person could get a decent Idea about what the porting should look like as well. I still have most of my grinders and polishers but lack the steady hand of youth. So on our latest project we neglected the heads but it runs well without the porting.

Very surprising data and improvement was much better than I thought it would turn out to be from such a mild first rip at basic porting.

I'm about to attempt this same "basic process" on a set of 225 V-6 dauntless heads and was somewhat discouraged about the amount of work cast iron heads will require. However, after watching your vid, ( and ignoring some of the info. Eric "I'm no Superman" Weingartner ) implores during his demonstrations , I have an entirely different attitude now. Eric is a true Pro, but he can over complicate the basics and for the DYI guy, he can discourage people to attempt the very possible good results from small changes making big improvements.

Thanks for a Great Video.

Wow! Great gains. With a .550 lift cam. The valve is @ those #s .050-.500 Twice per event. That's gotta add Power.

I am amazed that Richard Holdener NEVER ported heads before. You virtually live in a hotrod shop, so how can this be?

its a dyno shop

I like this episode...Thanks

Great content this round 👏

I think those are pretty impressive gains for the basic work you did, would probably need a bigger valve and lot more work in the port to get much more out of it. 👍🏻

Richard, if you are going to run this on a turbo, I have a theory that porting specifically for low lift flow would be more effective than porting for maximum lift. It would make a small cam act a bit larger, similar to a high ratio rocker effect. This might be easier to test on an LS where heads CNC ported for maximum flow are easy to find or maybe a small block Ford where really low and really high flow heads are available (sometimes with similar port volume).

I think this effect would be very visible on a turbo because at high lift you have both boost and back pressure that will make a lower flowing port work pretty well. I think low lift is where most of the restriction matters.

Richard has shown time and time again that whatever makes more power on a naturally aspirated engine also makes more power on a boosted application. Your theory is interesting but from what I've seen on his testing the better overall flow will always make more power.

@@1967davethewave well, if the theory is interesting, why not test it?

Now try a back-cut valve and then a 3 or 5 angle valve job.

@Richard Holdener great video! Excited to do my modular 4.6 32 valve porting.

could you do a Dyno test on whether indexing spark plugs is worth anything?

it is not worth power-only fitment with big dome pistons

Lapping a smear of paste and slow speed forward and reverse to get a uniform seat as the valves will revolve in service so perfect seat required.

Now make them all flow the same ;) Great video!

Should hit those valves with a wire wheel before grinding to get carbon and crud off

we do hit the valves with the wheel

Un shrouding the exhaust vale is basically worthless or counterproductive.

Going after the top of the the exhaust guide and opening up the bowl / throat to 90 % of the valve size would have been more productive, without any risk.

Just straighten out the straight parts and make the curved sections less curved while port matching. Raise the intake roof to a known safe dimension based on gaskets. Rough sand the intake port when done to cc match and polish the exhaust port to cc match. Polish the combustion chamber after un shrouding the intake valve while cc matching the chambers.

All the ports should match each other respectively.

After doing that there is very little left to be had without going overboard accidentally.

based on gasket?

Show us Richard 😃

Bigger intake valve might have alot less shrouding. And I don't know how much material is left.

Are these availiable anywhere in aluminium?

THERE WAS A COMPANY OFFERING AFTER MARKET HEADS-NO LONGER

I wanted to do a light blend on my 32v 4.6 ford but chickened out... not like 32 valve heads are easy to come by

Too cool

My n/a 3800 shows 12/ 1 at wot but as im going up to 5670 rpm it goes to 15/1 on AFR Table! I have ported and polished throttle body, cold air induction, heat sheilds, ported manifold, plenum spacer at 12 mm, 25 mm manifold spacer! The lower the engine temp? Feels great, jumpier over stock, pulls harder and gained .5 second at zero to 100 km/h. I need a bigger TB at 69 mm. Remapped ecu from mace engineering in Victoria Australia! It also shows knock retard at 15/1 AFR? the 4L60E needs to Remapped as well or a shift kit! Cheers from Australia subbed and liked 👍 ❤

15:1 is not good

@@richardholdener1727 yeah I'm wanting to get the ECU REMAP ASAP but it's only when I give it heaps! So for know I have to drive normal.

Oh yeah. I'm using AED diagnostics from envyouscustoms and I literally can't find any remapping software for tunerpro RT? I'm wanting to do hp tuners course? Otherwise I will have to pull the ECU out of the car and send to Victoria. Apparently 2 weeks turnaround! ( Apparently) lol 😆

Here's the problem. Richard Holdener is a more than competent mechanic (or engine wizard). He has years of experience and the proper tooling. I've seen dozens of heads destroyed by incompetent back yard hacks that think they are smarter than the engineer that designed the heads. There should be a disclaimer, "If you're a backyard hack, don't try this at home"

Every professional, experienced mechanic started out as a backyard hack. It is called learning by doing.

actually flows good for a stock head.

Neat video. 😊

Thanks! 😊

pretty good gains for first try!

The CFM you gained by porting should give you about + or - 5 horsepower per cylinder?

So we ask ourselves... what would Richard do (WWRD)?

Personally I blame squirrels

What is the bore spacing on the 3800, and 250i6?

Hey Richard, is your porting DV approved LOL. Thank you.

I'm sure he laughed out loud

Hey man question .?? Sooo there’s a rumor my friends are fighting over.. fully built studded engine for boost. Is it necessary to install Dow pins on the head.. now have any test been done with and without them ?! I’m all for installing them . I know they keep everything center and happy . Just was wondering .

Why do the heads need to be pinned?

I figured to keep the cylinders centered.

I have a Set of TFS Street Heat Cast Iron Small Block Heads I Need Ported . Were Can I Get them Ported . Thanks

TOTAL ENGINE AIRFLOW

12 - 18% improvement, with the bigger improvements at low and mid-lift. That should help power output.

How long did it take to do all 12 ports?

Did you find that porting is relaxing after you got over the initial fear of ruining it?

Did you use a tungsten carbide or high speed steel burring tool?

I only did 1

The written description under the vid says less than 45 minutes for one port. Assuming he gets quicker on the rest of them it would likely still be a full days work to do all 12.

🤔 You probably saw the typo. (Does is work ) just letting you know buddy .

Iv ported and slightly polished the head on my b204 and iv not yet fitted it but most people are telling me I should dimple it. However my understanding was that turbocharged engines and direct injection engines don't need dimples but need or prefer a polished surface. Am I wrong or do you think the advice is?

don't worry about surface finish

@@richardholdener1727 I thought if they are ruff it's good to get them smooth and shiny or is just smooth good enough?

I mean you got to finish it and Dyno test it

You will get them upto around 240cfm when finished

Sko buffs!!

Did you really go to school in Colorado is that ware your from ?

colorado?

Your cu buff sweat shirt

Are You using the Holly ECM on this one? If so You could use two sets of injectors. Upper set to inject methanol under boost.

Or pump e since this is more of a budget build 🤑🤑 lol

I thought you were an LS guy?

I'M A DYNO GUY-EVERYTHING NEEDS TO MAKE MORE POWER!

Remember: Boost is nothing without airflow! ;)

👍💪

GAINS!!!!!!!!

That flow bench is stupid. That should be automated, included data logging.

BTW, dollar store spray cans of oven cleaner can dissolve the carbon build-up on those iron heads.

you offering to buy them a new one? if it works why would they replace it?

@@bunter6 When cars were invented, some people still stuck to using horses. Do you want to move forward or stay in one place?

@@PCMenten Your an idiot, more like you want him to get a Mclaren when a Corvette will do? I'd love to own that flow bench.

@@derrickwhite6776 I agree that I’m an idiot, but with a bare minimum of effort, you can make a better flow bench.

Derrick, if you learn the difference between your and you’re (and yore) you won’t sound like an idiot.

@@PCMenten Okay, so you got me on the use of the word your, kinda explains a lot about the knowledge you have for flow benches.