RIM AND FACE ALIGNMENT FORMULA METHOD | TAMIL | Rotating & Static Equipments

HTML-код

- Опубликовано: 11 сен 2024

- TOPICS EXPLAINED:

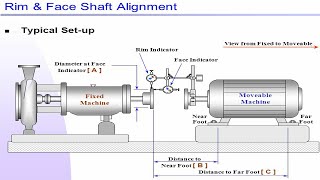

RIM AND FACE ALIGNMENT FORMULA METHOD COMPLETE PROCEDURE AND DEMONSTRATION WITH EXAMPLE READINGS.

PRE-ALIGNMENT

BAR SAG

VERTICAL MISALIGNMENT

HORIZONTAL MISALIGNMENT

ALIGNMENT CALCULATION.

SUBSCRIBE FOR MORE ROTATING AND STATIC EQUIPMENT VIDEOS.

/ @rasetech

RIM AND FACE ALIGNMENT FORMULA METHOD | ENGLISH

• RIM AND FACE ALIGNMENT...

HOW TO FIX SOFT FOOT ON SHAFT ALIGNMENT | ENGLISH

• HOW TO FIX SOFT FOOT O...

HOW TO USE AND MEASURE VERNIER CALIPER

• HOW TO USE AND MEASUR...

CENTRIFUGAL COMPRSSOR DRY GAS SEAL SUPPLY SYSTEM

• CENTRIFUGAL COMPRESSOR...

BELT DRIVE PULLEY ALIGNMENT STRAIGHT EDGE METHOD

• BELT DRIVE PULLEY ALIG...

RIM AND DOUBLE FACE DIAL ALIGNMENT FORMULA METHOD

• RIM AND DOUBLE FACE DI...

REVERSE DIAL INDICATING GRAPHICAL METHOD ALIGNMENT

• REVERSE DIAL INDICATIN...

HOW TO FIND TYPES OF BEARING BY BEARING NUMBERS

• BEARING NUMBER FIRST D...

RIM AND FACE ALIGNMENT FORMULA METHOD

• RIM AND FACE ALIGNMENT...

HOW TO FIX SHAFT ALIGNMENT SOFT FOOT

• HOW TO FIX SHAFT ALIGN...

#rotatingandstaticequipments #rimandfacealignment

Dear Friends,

Recently I have uploaded english version of this video in our channel. Kindly please check it out. Thank you.

ruclips.net/video/SAaGINqGg-8/видео.html

வணக்கம் என்ற வார்த்தையை கேட்டதும் எனக்கு அவ்வளவு மகிழ்ச்சி!!

தொடர்ந்து தமிழில் ஒளிப்பதிவு செய்யுங்கள் அண்ணா!

Nandri anna

Great video and usefull content even I don't understand your language.. .

It will be very nice if translated in English. Thank you Sir and greetings from Morocco.

Thanks for your valuable comment. I will try to upload in english.So stay tuned.

Please share this video in English.

Please make in English..we don't understand..

We want more videos in tamil..., ( உண்மையில் அழகு அண்ணா )

Thanks alot for your support.

மிகவும் பயனுள்ள தகவல் சகோதரரே.

Iam millwright fitter so very usefull. Thank you sir

Thanks for your comment❤

👍 your explanation very good👍

Thanks for your information @ need more details like accepting criteria.

madhusudhan yemmina actually accepting criteria will depends upon rpm and coupling or shaft diameter. Thumb rule is TIR should be 0.05mm or below

This video is very use full sir so thanqu so much .......

Thanks for ur comment. kindly share this video to ur friends also.

Bro your videos are very informative and effective thanks.

Please put videos for vertical in line centrifugal pump allignment procedure.

And the tolerance for allignment as per API 570 pumps

Noted with thanks bro

Thank you bro ungalala 1lakhs vankuran

Thank you bro... I am so happy... all the best...💐💐💐❤❤❤

@@rasetech thnks bro

Nice video sir,good explaine.🙏

Nice explanation bro tanq for this video ....tanq so much

Congrats brother...Gud explanations....

Thanks Anna.. Tamil la upload panunathuku

Welcome

Fabulous god bless you

Sir your basic about rim and face alignment is so nice, you clearly explain each n every point,but some how I understand few bcoz language in tamil, sir try to explain in English or Hindi.

Dear sir, Thank you very much for your valuable comment. I will try to upload sir.

@@rasetech

pls sir we will be grateful to you if you upload your videos in English language too.

Regards

@@GAURAVKUMAR-in2yg please stay tuned. I am sure that definitely i will do .

Sir you are so so very Good,i love your teaching,Keep it up Sir....i wish you did it in English but i understood a lot

You are most welcome sir. Stay tuned. I will do this videos in english also. And kindly see my centrifugal pump overhauling procedures english video and give your feedback please. Thank you!!!

ruclips.net/video/LmOE42hc38M/видео.html

Sir i have confusion regarding signages.your vedio is showing positive value for both rim and face reading .but if we found dial indicators showing negative reading for eirher rim or face reading whether we need to.consider +/- sign in formula or not?

Very very important Vedio

Nice job

Gaurav Choudhary thank you...

Very very knowledgeable for all

Sir hindi language more useful

thank you sir

Very useful Thanks...

Thanks for your comment ..❤

Sir make vertical mount pump alignment video

Noted with thanks ❤

Please update for spherical pad bearing alignment in steam turbine

Great explanation. Thanks. What is the allowable tolerance level

+/- 0.05 mm

@@rasetech thank you gentleman.

Hi.It will be gogd you show it in workshop with real pumps.

Thank you in advance.

welcome bro

Very nice post

Thank you

Super video sir

Sir,Is it necessary to put Radial and Axial Guage together at only 12'o clock position . if I fix Radial Guage at 12'o clock and Axial dial guage at 6'o clock will it help me with Rim and face formula method. Thank you

Sir pump overhauling video pannunga please centrifugal and reciprocate both

Please share your all video in English including this one.

Ok sir thanks for your comment

please upload videos of turbine to GB and GB to alternator alignment procedure.

pls tamil videos

Sir can you translate video in English or Hindi. It will help to lot of people.

Thank you brother....

Antony Felix you are welcome bro...

Bro rottating equipment course enga padikkalam indiyaavula.ethu best institution konjam solluga

india la rotating equipments pathi course padikiradhu enna keata 100% waste of time. waste of money. neenga practical la learn pannunga appo than adhu unga kuda life long varum. enna keata na course and institute lam suggest panna matan enaku andha mari institute unmaiyave theriyadhu bro. better neenga unga work la practical ah learn pannunga and ungaludaiya senior kita irundhu experience ah gather pannunga adha unga job la execute panni parunga. idhu kandippa workout agum bro. thanks alot for your comment. dont waste your money.

@@rasetech Bro thank u .ana dubaila interview pogumpothu kandippa course mudichhu erukkanum nu ethavathu cetrificate keakkuraanga.ok thanks for ur suggestions bro

@@agpsooraisoorai1757 Sorry Bro adhu pathi enaku theriyala. Incase apadi keatanga na na already degree or diploma complete panni irukan. then Thevai anna Alavu ku experience gain pannitan so Training not required. apadi sollunga ungaluku venum na enna test and check pannikonga nu sollung bro.

Sir, very nice videos, get lot of information, can you explain how to find out angular misalignment reading on dial guage

thank you sir, by practically you can find sir.

You're better

Check 17 minute ... Reading+ reading - ... + Remove sim _ add sim

vera level bro...

thanks bro

Please make master level caluclations and how to check

Good

Thanks

very useful video sir, but please make in hindi

Ok sir i will try

Super bro

thank you bro

Bro asking one dout video 21:51 horizontal misalignment how to move front and back (right and left ) position clearly because motor side 4 sides jack bolts totally so can u explain for one more separate drawing and reading value movable method

Noted with thanks....❤

Sir very very important Vedio but tell in hindi

Sir tell about reverse alignment in English or Hindi

ok sir sure i will do.

I have one more doubt about horizontal reading. If you set 0 at 9 o'clock to 3 o'clock position and take a face reading - 0.2 and rim reading - 0.3, it means dial plunger extended if you look motor from the backside. I think we have to jack for the right to left. Can please explain and why not 0 sets noon to take reading 6 o'clock position for the vertical corrections.

Bro bar sag check pannama alignment qnd calculation panna mudiyuma?

Pannalam but bar sag value error alignment ah fulfil pannadhu...

Sir pls do video in Hindi or english

A)Me podría explicar cómo o De dónde saco los +0.6mm si el comparador de borde por lo general a las 12 se ajusta en 0?.

B) los -0.04mm pertenecen a la deflexión del eje motor?. Para que los utilizo si no van en la fórmula a lo igual que la separación de acoples tampoco se consideró en la formula

Please ask your question in English. Sorry for the inconvenience.

Please make master level caluclations and how to check readings and correcton

Received with thanks

Dear sir ..... Very good teaching sir . But I heard, if the value comes in + we have to add shims ....but you said remove shims ....i confused sir .please clarify it .

Your saying in reverse alignment and laser method

Thanks

Very good and informative video but only problem is that we don't understand Tamil so can you speak in English so that we can understand properly thanks

Still waiting for your eng version

Garecoupling elnment foralam

Muy buena la explicación de la alineación la puedes colocar en español. Muchas gracias

i am sorry. I dont know Spanish.

Estimado señor, disculpe las molestias. no se español Intentaré subir este video en inglés. gracias

Consulta.

los -0.04mm pertenecen a la deflexión del eje?

De dónde saco los +0.6 si a las 12hrs el comparador siempre se ajusta en 0?

Bro intha alignment praticala na pratice pannanum ethachum center erukkuma.

Waste bro neenga unga site laiye practice pannunga bro

Super good information

🙏❤

Please explain alignment reading in graph paper

Sorry I dont Know..

Thank u sir motor A B C alava eappadi measure pandrathu ....next video pannugga sir please

dear sir, enaku electrical motors current measurements la theriyadhu ji. but i will try.

Could you plz explain these two videos i.e rim & face and Reverse method in English or Hindi.

Sir F Dial Front side fix pani reding eaduthu

conclusion pani soillirukiga aana some coupling gap just 8 to 2mm only apo F Dial la back side tha pana mudium apo reding - + change aagum la sir so F Dial back side set pani

conclusion kuduka sir

adhu apadiye sign mathika vendiyadhu than bro. simple than bro. na video panna try pandranga bro

Thankyou bro

Most welcome bro

Brother naama alignment check pannum pothu yevvalavu value erukkanum means maximum yevvalavu erunthaa acceptable

Total Indicating Reading + or - 0.05 mm irundha acceptable range bro idhu vandhu thumb rule. But Idhu RPM kammiya irundha konjam values increase agalam according to the range

Thanks bro

Tnx bro

It looks like the horizontal movements are in other than the way what you said ....

நன்றி சார்...

Nandri

Why the value/number for the R is = -0.04 and + 0.6 ?

I mean why one side ( one point) didn't start from 0?

Dear Sir,

Thanks for your comment...

Kindly see the english version of this rim and face alignment reading for more clarification.

ruclips.net/video/SAaGINqGg-8/видео.html

sir can explain hot alignment (steam turbine to pump )

i will try sir

Super Anna. Yanaku oru doubt irukku. Barsag sonninga athu kandippa yadukka veanuma ,big shaft LA yappadi yedukka midium please reply me anna

Ella machine laiyum edupanga bro. adha base panni standard ah oru fixtures ready panni vaipanga pa. ellam time individual ah check panna matanga but fixtures standard bar sag free ah vachi irupanga pa. ok va

How to make offset after alignment?

Rim and face alignment Hindi me video banaiye sir

ruclips.net/video/8xeIqVVPFN4/видео.html

plase explain about Seal flushing plan

I am already explained about seal flushing plan in my channel. Kindly go through it from my channel. That video name is Basic of mechanical seals part 1.

ruclips.net/video/sKnYVoxRDOg/видео.html

👍

Sir plz make the same video in hindi or english plzzz

Sure, i will do it

Pl share your video in english

ruclips.net/video/SAaGINqGg-8/видео.html

How to find out Motor left and right. Is there any thumb rule

Horizontal Misalignment answer is + means the motor is in the right side. if the answer is - means the motor is in the left side. Actually there are lot of rim and face alignment formula method. In this case this is thumb rule. Kindly watch this video from after 20.30 mins

@@rasetech sir that is clear

But from which side we are viewing i.e from back side of motor or from front of motor

Kaushik Faldu from motor cooling fan side.

@@rasetech great!!!...thank you sir

Kaushik Faldu all the best...

Ji bar sag, first r sonninga...

Reading note pannumpaothu f la panringa.... Pls clear dis????

ji illa ji rim la 6 to 12 positionla mattum the bar sag minus pandrom ji still ungaluku doubt irundha again porumaiya video va parunga illana ennoda number ku whatsapp la contact pannunga ji na solranga +96596650914

Understood tanks for your response.. like and subscribe done

Leo Latheef thanks for your support.

Hi bro

Please put video on static equipment alignment.

Kindly ask elaborately about your static equipment alignments

@@rasetech pls post a video on how to align a vessel with skirt support

@@narendhirabhoopathy1343 Sorry to Say. Actually I don't Know about this Vessel Alignments. I have Experienced in Maintenance works only. I am extremely sorry for that.

kindly tell us in english or urdu or hindi

Waiting for your next updates

Dinesh kumar my next video about mechanical seal

@@rasetech super super super

Intha alignment both axial and radial alignment?

Sir your example rim(radial) -0.04mm bottom 6o'clock or 0.06 mm top 12 o'clock ,you take 0.06 in calculation ; here we shroud take 0 digree to 180 digree rotation reading ; sir please send your no .

mukesh kumar Dear sir i cannot understand your question. Kindly intimate in detail.

Dear sir... from the radial reading in 6 0 clock position we will set -0.04 mm instead of zero in the dial indicator. Because that is called bar sag of rim dial indicator. So we have to eleminate the rim dial indicator bar sag value while taking reading. If u have doubt kindly cal me in whatapp +96596650914.

Halo sir...

For this method, do dial indicator has to put in shaft of pump..?

Thanks

Fix the pump and correct the motor to align. so Fixtures should to be fixed in pump only.

What is soft foot & How to check soft foot missing brother...

My next video about soft foot only dont worry...

Thnx bro

Rim and fash alaiment farmula keya hai Hindi

Dear Friends,

Recently I have uploaded Hindi version of this video in our channel. Kindly please check it out. Thank you.

ruclips.net/video/8xeIqVVPFN4/видео.html

Hello any course about this in tamilnadu any places

Dear SIr,

I am so sorry, I dont know.

@@rasetech laser alignment procedure??

ruclips.net/video/7QeJBNPkDdI/видео.html

Anna intha allignment la parallel And angular misalignment rendumae correct aagirumla

Yes bro

@@rasetech then what is the use of rim and double face Alignment method?.

What the use?...

Please explain in hindi or English

Shotput value enna

Sir please in english

Ok sir

Bro, + means add shims in doubles face but 1 face reading + means remove shim? Clarify bro..

Rendu videos laiyum reading eduka kudiya positions parunga bro... rim and face la bottom to top reading eduthu irupom bro... then rim and double face la top to bottom reading eduthu irupom bro adhan sign change agudhunga bro thank you...❤

Plz say Telugu also

Plz explain in english

anna ippo pump pump overhauling pannambodhu bar sag edukalam ana field la poi bar sag epadi edukanum?

Bar sag epadi edukuradhu nu na oru video upload panni irukanga adhu parunga bro.

@@rasetech anna normal rod la kuda bar sag edukalam eh?

@@SaiVivek01 adhu ungaludaiya clamp fixing pandra diameter ulla rod use pannalam bro

@@rasetech bro unnga contact number kadaikuma?

@@SaiVivek01 send me your whatsapp number

Upload video in English or Hindi ,not any regional language

Ok sir

Bar sag na ena bro

ruclips.net/video/BjaKWIZXVWQ/видео.html