1-9 Shaft Alignment Measurement Basics

HTML-код

- Опубликовано: 11 окт 2017

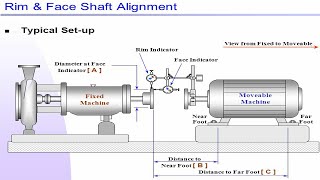

- The major topics in this tutorial will discuss the basic roughing in techniques for your initial alignment of machinery. You will be introduced to the five primary alignment measurement methods. We will also cover how to override a runout condition when taking your measurements.

Наука

Наука

Thank you very much! Clear and very informative - information I needed to know & apply.

john what a great presentation on 1-1 thru 1-9.your books are wonderful,as technology moves us along,you tube studies can help as well. I am a service technician in the rotating equipment industry. this has been hours well spent,thank you for work,helping us all.Andy Haslam

Thank you for your kind comments on the training videos! We will be publishing the last training video in the Introductory series here shortly. Eventually we will be publishing the Basic Shaft Alignment Tutorials (6 tutorials - totaling 4.2 hours), Intermediate Shaft Alignment Tutorials (9 tutorials - totaling 7.8 hours), and the Advanced Shaft Alignment Tutorials (5 tutorials - totaling 4.5 hours). The Basic, Intermediate, and Advanced tutorials will be available on a Pay Per View (PPV) basis but that's not going to happen until we hit 10,000 total views or have 1000 subscribers. If you think the Introductory tutorials (free of charge) are valuable to you and your organization, the Basic, Intermediate, and Advanced tutorials will provide you with a plethora of information that will help you solve any industrial alignment problem. Thank you for watching!

John Piotrowski

Andy - Thank you so much for your kind words. John Piotrowski

thank you very much for ALL informations

What a super explanation 👌👌👌💕💕

Dear sir, thanks for the videos. Your videos are really great. Kindly upload videos about vertical alignment methods and double face alignment.

Hi, great speech at the end, thank you!

Thank you for watching.

Superb tutorial. Thank you

Stephen: Thanks you for the kind words. Hope the information helped you in some way. John Piotrowski

Great teching techniques. It's great to watch.i M also millwright. In training periods

Prashant: Thank you for the kind words. I hope this information will help you. John Piotrowski

Muchas gracias por la explicación.

Buenas

Muchas gracias por la informacion, apesar que entiendo un poco el ingles, seria bueno tener todos estos videos traducidos en español o tener textos . Algun sitio que me pueda recomendar.

gracias.

While taking the readings using dial gauges whether both coupling hubs can be connected using some solid piece or we need to do something else to make sure that both are rotating together. While aligning the gearbox shaft with the motor shaft, it is difficult to rotate both hub together and take reading at same position without connecting it using a solid piece.

Ashish - You can keep a flexible coupling engaged during the alignment process but there is a potential issue when doing that as described in tutorial 1-11. I understand that some shafts are difficult to rotate, sorry. If you do not have an excessive amount of runout (i.e. 1 mil or less), then you do not have to rotate the shaft since the outer perimeter reflects concentricity with that shafts centerline of rotation (within 1 mil).

Thanks alot for very informative videos , Please we need to see video No. 1-10 & No. 1-11

Thank you for your kind comments on the training videos! We will be publishing the last two training videos in the Introductory series here shortly. Eventually we will be publishing the Basic Shaft Alignment Tutorials (6 tutorials - totaling 4.2 hours), Intermediate Shaft Alignment Tutorials (9 tutorials - totaling 7.8 hours), and the Advanced Shaft Alignment Tutorials (5 tutorials - totaling 4.5 hours). The Basic, Intermediate, and Advanced tutorials will be available on a Pay Per View (PPV) basis but that's not going to happen until we hit 10,000 total views or have 1000 subscribers. If you think the Introductory tutorials (free of charge) are valuable to you and your organization, the Basic, Intermediate, and Advanced tutorials will provide you with a plethora of information that will help you solve any industrial alignment problem. Thank you for watching!

John Piotrowski

Could you please tell about any international standard which mentions about misalignment and can be used as a reference

Ashish - We just finished the first two shaft alignment standards through the American National Standards Institute (ANSI/ASA). Here are the links:

global.ihs.com/doc_detail.cfm?&csf=ASA&document_name=ANSI%2FASA%20S2%2E75%20PART%201&item_s_key=00733271&item_key_date=910528

global.ihs.com/doc_detail.cfm?&csf=ASA&document_name=ANSI%2FASA%20S2%2E75%20PART%202&item_s_key=00741967&item_key_date=910528

We are currently working on a third standard for alignment of vertical oriented shafts. An International standard has not been developed yet. My personal opinion is that is quite a shame that no one has attempted to create ANY kind of standard for shaft alignment until we started this about four years ago here in the United States. I'm not sure what the procedure would be to submit the US shaft alignment standard to the International Standards Organization (ISO) for acceptance by other countries but I will attempt to find out. Wish me luck! John Piotrowski

Shouldn't the coupler be disconnected when checking with dial indicators?

Cap'nPZazz - You are correct. A flexible coupling should be disengaged when measuring shaft alignment positions as moderate to severe misalignment can elastically bend the shafts causing erroneous measurements. A rigid coupling should always be disconnected prior to taking alignment measurements for the same reason.

Muchas letras, pocos números.

thank you very much for ALL informations

Tim - You are very welcome. John Piotrowski