Design & Build of a Flying Wing (With Balsa Wood) + Project Files

HTML-код

- Опубликовано: 11 сен 2024

- This is an amazing flying wing project, using classic balsa wood construction and covering. You can learn more in the dedicated article: bit.ly/3FpuGCk there you'll find all the information and download all the files of this project.

Wing Helper video: • Designing a Wing Struc...

Download the plans and files: bit.ly/3FpuGCk

Wing helper software: www.winghelper...

NanoCad: nanocad.com/

Software to cut with laser: lightburnsoftw...

Laser cutter: bit.ly/31TquNE

FrSky servos: bit.ly/3K80aR1

Useful links to connect with us.

Join our Discord server: / discord

Website

joyplanes.com/

Become one of us:

goo.gl/zKQ706

Facebook

/ joyplanesrc

Instagram

/ joyplanes

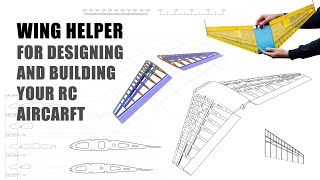

Wing Helper is a state of the art 3D CAD program for design of RC plane models. Wing Helper is oriented towards ambitioned RC modelers, who are beyond building models according to ready made plans, and who want to start designing, building and flying their own creations.

This video can help you understand a few principles about designing UAVs from scratch.

#JoyplanesRC #HobbyRC

Not an engineer you say and design , laser cut , build , adjust and fly an R.C wing , i dont know about others that is more engineer than many people out there in this world even with university degrees. Fantastic work , designing an RC flying wing has been my dream I have built a lot of free plans but always wanted to design my own.

Thank you so much! What you say is true, so next time I'll say "I don't hold and engineering degree" hahaha Cheers.

Very nice build and color choice. What a great help of a laser cutter. 40 years ago we did it all by hand. Can you really do all that in 3 hours? Congratulations!

@@paulbrouyere1735 Only the cutting, but that was just an estimation, it might take more and omitting the inner holes.

it's good fun wings are easy on foam..kf airfoils. but I made a high wing model once just simply a box fuse an a wing an tail an it flew amazing it was on rails I couldn't believe it flew so nice for a long box with wings lol

Well said, Aakash Jana.👍

From what I've seen on other wings they do like a bit of reflex when flying. A few degrees (2-5) of up elevon should do it.

The old school way of building aircraft has its charms! Laser cutting is the way to go! I used to design and build my own planes many years ago, I built my own foam cutter and made foam wings instead. Downwash is very important for flying wings. Perhaps you can add a boom to lengthen the lose and use less nose weight. A longer fuselage "may" reduce the spin an also the tip fins could be taller also.

This is really fantastic. Love your build. We cut and build our wings from foam, but a bit larger in size. As a suggestion, I would do everything possible to shift weight to the front rather than add nose weight. (1) move the servos further forward- with a plane this light your should be able to use really small servos (2) Make sure the elevons are tapered and thin balsa (3) Cut the back in a bit to move the motor mount further forward (towards the CG) (4) position the battery as close to the front as possible and use foam to cushion a crash. Do the same with the rest of the electronics.

I think you did an impressive job with all the work that went into it.

Thanks so much for your advice on this!

You can try using reverse tapered elevons like the original Zagi flying wings. It's a genius design in my opinion. When you pull elevator control "up", the broader tip of the elevons reduces the angle of attack of the wingtip, preventing it from tip stalling. Even when the airspeed decays with a full "up" elevator, the wing will just bob its nose up and down with full aileron controls. The Canterbury Jazz Extreme uses constant chord elevons that will tip stall and fall out of the sky like yours when we do hard maneuvers for slope combat.

Yes you can just tape on different elevon extensions near the wing tip in order to test this idea but it's the same idea I was thinking. Also consider thinner Balsa or foam board something extremely light for the elevons reducing weight at the rear of the plane is better than adding weight to the nose.

That's a very beautiful plane! The wingtips look a little small though. That might be the reason you spin so much when you stall, as there is not much yaw stability at low airspeeds.

Love the way you are using a laser to build your aircraft. May I suggest a couple of tips to help with your laser cutting? I would recommend you to raise the balsa wood sheets above the laser bed to allow air flow underneath. Even better, use a metal honeycomb bed. Install air assist on your laser head. This makes a huge difference to the cutting ability. Plenty of tutorials on YT to help. Keep up the good work 👍🏻

Elliptical wings are theoretically the most efficient. Tapered wings are almost as efficient but with the aerodynamic efficiency comes a less stable wing that is prone to tip stalls. So there is a balance with the amount of taper. More taper is more efficient but less stable. Your wing has a lot of taper. You can try extending the chord length at the wing tips. This is probably the most aerodynamic option to reduce tips stalls. More washout might help. Vortex generators near the wing tips is an option but I don't know how effective that would be and it defeats the purpose of a tapered wing. You can try slats near the wing tips but it will also increase the drag to lift. Hang gliders have a lot of washout for the same reason. Rigid hanger glider wings are tapered far less and have much less washout. In an RC plan, I personally don't like the idea of washout since you want to do aerobatics and inverted flight and the washout then becomes counter productive.

By the way, it is a real nice looking wing and looks like it would be fun for park flying.

Check out Nurflügel wings, they are more efficient than elliptical wings if your calculations include the mass of the structure of the wing.

@@Br1ckInTh3W4LL You can have an elliptical flying wing as well as a tapered flying wing. Elliptical is just a theoretically efficient wing like a Spitfire. You can also sweep an elliptical plan form.

Add nose weight and then reflex (up trim) to accommodate.

My foam me163 build is about that size and it needed a lot more in the nose than calculated. In the first iteration (you.can see the maiden on my channel) it tip stalled badly. I had full length elevons like yours here it was also super sensitive so i I shrunk the elevons by 30% by cutting the tips off, adding a new section of wing and adding washout. That way the tips werent ever in a situation where the elevon forced it to stall. That helped but didnt completely fix it so I added wing fences midway down the wing very much like the early mig 15 and 17 had. That stops the stall early, doing it midway down the wing allowed the remaining elevon to retain some control during stalls. It is now so steady that I havnt had a tip stall since. You can see how much better it flew in the remaiden video.

The fences will be super easy and should make a huge difference.

nice video! try splitting the elevons into elevators and ailerons, but put the elevators in the 30% of each wings span at the wingtip that will washout the wing as the elevators r trimmed up to keep the nose up. it will also reduce tip stall when slow flying. with the ailerons on the inside 70%, when the aileron moves downward to lift the wing in a turn it also washes out the wing causing the vortex to shed at the end of the aileron which modifies the airflow upwards tilting the lift vector forward so the u create Proverse Yaw to coordinate the turn.

Hey, @captarmour I am really pleased by the solution you gave, I am an undergrad student and love aerodynamics. Would love to connect with you if possible! Thanks.

@@vardhanshah5283 did you actually try it?

Your idea to twist the wing does help a lot. If you swept the wings back a little farther, place the servos a closer to the front(longer rods), or a dihedral on the wings might give you just the stability you need. adding weight to an aircraft is counterproductive. An excellent first variant.

Amazing little flier! IMHO you need to design a set of vortex generators for the wings and definitely use more nose weight! Most of my planes are wings and as a rule I am using at least 10% more nose weight with bigger batteries or moving it forward. Happy flying!

I second the use of vortex generators. I had a HLG that tip stalled when trying to turn tightly in thermals. I used clear plastic laser printer sheets cut down to 10mm wide strips with tabs 1-2mm wide cut along back edge bent up 1mm. These were placed 1/4 chord back along the outer 1/3 of the tip. This got rid of the tip stall issue. With HLGs you want to avoid being nose heavy.

Thanks for all the resources you provide plus the well filmed account of the build. I have an ambitious idea for a flying wing or blended wing body with no control surfaces. NASA is experimenting with control through changing the wing shape and through ducted air to maximize efficiency and minimize weigh and complexity.. My idea is simpler. With two ducted fan motors internal and a simple system of louvers but a slightly more complex internal system of ducts to achieve yaw pitch and roll, control air is preferentially ducted or thrust raised or lowered to four slats on the upper and lower surfaces of the wing. The thrust slats are such that they are offset in two dimensions to control pitch and roll through louvers and to control yaw through varying thrust on one side or the other. The possible geometries for such a design are not that complex and are potentially very bird like with thick wing chords and a thicker body to contain two fan Moros and the ducts. The biggest challenge is the control logic which could be established through bench testing prior to flight trials. An even simpler design uses four motors and no louvers to direct thrust. Each slat has a dedicated fan and all control authority is through changing thrust to the slats. I wonder if you are interested in doing such a build yourself or collaborating with another RUclipsr for a special series? I don’t have the resources to do the build myself at present. I know however this is cutting edge stuff that has not been tried by anyone yet and would make a great ambitious project.

try to use an autostable airfoil, like broggini 55509.

those airfoil are known to add more stability in flyng wing configuration.

Thanks for the tip! I should have done that before cutting the whole thing. Next time I'll try that airfoil.

@@Joyplanes PW-51 is also good. That's similar to what's on the very popular Nano Goblin

Cool tech, that laser cutter. I built most of my rc planes in the nineties, well before this kind of tech was available for consumers.

I was surprised at c/g calculated at center of wing. I built a few deltas and flying wings, and begin from c/g at 25% from the leading edge of the theoritic chord, and that was flyable every time.

Fun to see people building rc planes with different techniques. Keep up the good work!

Add a little reflex in your elevons. For your little wing I would say maybe 4mm of reflex basically trim them up until you can fit a 4mm block between a straight edge and the elevon where it meets the fuselage. Also flying wings LOVE a nose heavy configuration. Winglets that extend back beyond the trailing edge of the wing will help and if they are angled slightly inward at the leading edge and slightly outward at trailing they will help with stability. The tip stall your experiencing Is common to a flying wing design as there is little vertical stabilization. You can counter this with a small amount of dihedral (wing tips elevated a bit higher than the center). Flying wings can carry tremendous weight and love to be heavily loaded and fly fast. Enjoy! Excellent video!!

Thank you sir!

One possible trick to move weight to the front without changing the structure could be to replace the axis of the motor just by a longer one, so the propeller can stay where it is. And thank you very much for all your videos. I love watching your projects.

I did almost the exact same thing last month. I really like the design the program spits out. Will definitely study the design this program generates.

wow this is beautiful wing

What a coincidence, I just finished building my self designed wing a few hours ago! Maybe you could try to extend the winglets below the wing to make a wingtip fence. What would also probably help is a little reflex if you dont have any. Tbh though I fear that your wing has too little wing sweep and therefore has a very sensitive cg but adding more noseweight should also help

Thanks for the advice!

Hello! Fully agree! Bigger rudders to reduce sideslip and adverse yaw. This could avoid the subsequent assymetric stall leading to a spin. Beautifull design :)

I like your design and your video, good job! I have alot of experience with this kind of work and here's a few tips for future builds:

1 - use CA glue instead of the UHU stuff, it makes for quicker assembly and lighter frame since you need so little glue

2 - use Parchment paper instead of wax paper: even CA will not stick to it

3 - use a few laser cut parts to build a jig that holds your wing structure at the right geometry while you assemble to "hard set" the washout of the wing precisely (address your tip stall issues)

3b - use a piece of glass to glue your jig on to and hold everything straight and solid. a razor blade lets you clean the glass after.

It looks beautiful 🤩!

Thank you!

Good work, Watch almost all your videos and people like you are an asset for the hobby.

That would be stunning at night with some leds in it

Excellent work, I like the wash-out on the wing tips, not many people know about that. 👍

Kites use tails to prevent stalling. Nice job!

Try adding a 1/4' rib on the top of wing probably along each actual rib. Look at modern commercial Jets. They have these along with the little winglets at the ends. This reduces stall because the air doesn't readily move down the length of the wing. When these are in place

Also please make a detailed video on the software "Wing Helper"

That will be the next video but it's creator already did a nice long video explaining everything.

You have chosen an airfoil with a flat bottom from the spar to the trailing edge. That makes the wing sensitive to pitch, as the center of lift moves forward and aft with changes of the angle of attack. I suggest making the same model with an airfoil designed for flying wings. Martin Hepperle designed many airfoils for models of flying wings, all of which are freely available in polars and coordinate lists. I suggest the MH 60 airfoil for this model as it has mild handling and good lift.

Thanks! but I did use the MH60, at 1:29 you'll see I stated I'm using that airfoil, I think that fuselage is also creating lift and interfering with the CG.

@@Joyplanes No kidding, I don't know how I missed that! It sure looks like a regular flat bottom eppler or something in the video. You must be right about the fuselage. Maybe a symmetrical section in the fuselage would calm down the handling. At least it would be relatively easy to test without constructing another airframe.

Hello and thank you sharing your way of building and tools. Too often we have to pay, or just stay in pain without knowing which tools where used.

For the model, it a bit too small for me but it's my taste of flying little bigger wing. Between 90cm and 130cm

I think you miss a bit of torsion on the building to stabilize it. And winglet could be higher to see it aft like rudder at the launch instant. I never launch handling the wing by extremity for avoid the snaking, but it work very well if you have counter action by passive (rudder or winglet ) or active by mix on transmitter.

I prefer launching in center axis with or without propeller depending on model. For those with running engine I add an underneath center profile like piece of wood for hand catching and protect a bit at landing.

Continue your channel, building is so nice that all of us that do not try it, miss the essential of this hobby 😇

Check out the Stryker from Horizon Hobby. They have made at least 5 different generations of it. I personal favorite is the F27Q which has rudders. It's stall characteristics are perfect and you have amazing control while stalled. It stalls flat and you can deliberately put it in and out of a spin at will. You can fly it post-stall an entire flight and land it vertically like a helicopter. Okay more like a parachute.

The F27Q not only has rudders (which are quite handy in spin recovery) but it has lerx (can it be lerx on a wing?) leading edge cuffs and wing fences. All would require a lot of work to mod your wing but wing fences should be an easy experiment that you could first try using cardboard etc. You could also try adding strips of vortex generators on the wing tips. That would be the easiest mod

that is badass. consider using a bell shaped lift distribution. it produces pro-verse yaw and makes the flying wing much more maneuvarable

Nice looking wing you have there!

The wing looks a lot like those EPP wings from China. With one exception - the EPP ones have much wider wing chord at tip. I have flown one, and removed the tip plates as unneeded. Still the model shows no signs of tip stall. So I'd guess making the tips wider might help with the tip stall:

About the CG issue: how about cutting the wing center section "shorter" from the rear, and thus taking the motor forward? This should help to move CG forward without the need to add ballasti to nose. For wing strength, the part near the wing spar is the most important anyway, so making the center narrower should not make the wing weaker.

So many people has mentioned the tip cord, so I'll definitely consider that next time.

Looking forward to cutting and building this. thanks for sharing!

I used to design and build my own planes back in the 80s as a kid -- and my feeling looking at yours is it's really overbuilt; I guess that's great for enduring crashes though.

Of course I never had access to CAD, electric drive or much money, and most of my builds were just kind of intuitive and probably sucked, but they could fly somehow.

It's really cool to see you experimenting.

I agree. It looks like the plane only needs half the amount of ribs used and the fuselage section and elevons could also lose over half its weight with lightening holes cut out.

No washout? Great, informative vid. Thanks for posting!

Edit: Ahh... I see you noticed after watching the whole of your vid... 👍

You've got a biiiiig open surface for the entire wing, but then these huge winglets for stability.

Yeah they prevent tip stalls and provide some degree of vertical stabiliser, but they also induce massive wingtip vortices, which causes instability.

Since you can design it, have a look at "flying wing vortex stabilisers" and see about staggering some just above the laminar separation point on the trailing edge.

it's hard to curve them up in balsa ... if he adds some mid body stabs as you suggest will lose the best part of his design.

My advice.. I'd add more sweep to the wing allows you to get a more stable wing less pitch sensitive and ad more nose wieght

Like others have mentioned more reflux might help. Also consider changing the linkages for less throw unless roll rates are already too slow for you.

Seems like you know what you are doing. So I will leave no comment other than, beautiful model and well done .

I agree with the above comments regarding your wingtips. The cord does want be less than about 3.5 inches 85 mm.

Any smaller and the Reynolds number just goes bad (too high) !

Lovely looking wing - I have made some a little smaller. They had their own issues but not tip stalling.

Great to know, thanks for commenting.

Perfect making it

wow i wish i had that 3rd btw

Really nice!

Yes this is beautiful

9:01 that side profile of the wing looks nice

Could try using half control surfaces (outer most) possibly extended in width and check thrust angle (usually pointing down towards CG)

And possibly extend the winglets/make more surface area going backwards like a triangle

move your motor 3 - 4 cm up front by cutting your fuselage . reduce the "elevons" size next to the propeler and if you feel that you don\t have control you can make them bigger outer wing. servo must be in front near the leading edge as posible .... 9g in front of the CG is better the 9 behind even if your control rod will be longer.

Absolutely gorgeous build amazing!

To make it quieter move the propeller one prop-radius away from the trailing edge. . .

Or rather cut away the trailing edge to get the same effect without affecting the cg.

Very nice. My learning curve is nearly at 90° vertical.

Increase the depth on the ailerons at the tip which would increase the overall depth of the chord at the wingtip.

For a larger wing ... four lift fans like a quadcopter but then 2 fans tilt forward like tractors? Best of both worlds and more recoverable.

uptrim on elevons aka reflex an some shims on the top of the motor mounts for a bit of down thrust to stop full power climb's. an if it still climbs I add a mix that adds down elevon as power is applied so at full power the reflex is mixed out. I have a 24inch wing just like this and it flies amazing fast or slow.

In my opinion, add more of a vertical wingtip (rudderlets) to pull the vortex away from the trailing edge of the wing. I used 45 degree angles pointing out away from the wing. it would look more 'X-WING' if you did it like i'm thinking. Looks great and nice to see some balsa in the air again for a change bud. BEST of luck in getting it flying perfectly my friend. It looks to be close to having those perfect flight characteristics you're looking for now in the video. I honestly think that fix would do it. Let us know what it was that corrected it. :)

A well designed wing needs no vertical surfaces - this is the first launch of my latest wing

ruclips.net/video/rTtsHPIt6ec/видео.html

wow amazing!

Lovely model.

More weight wiil help...and be sure that you have differential throws on the ailerons...good job

Unfortunately I cannot offer any help, but I thing it’s great you design, make and fly. I am sure you get this working correct and and then golden-weight 👍🏻

Jack Northrup would be proud man. :)

Nice and crispy...

Superb looking build. Try lighter servos's with that weight there are a number of alternatives, and you may even find the small linear servo's (LSM1300, or 1.5g linear servo's, or rotary HK5320 ) would help knock 10g off the back edge. Move the motor forward making the centre section slightly shorter or recessing the mount. Also, did not see the spec.s of the motor, you may get away with a smaller one? If it was me, adding 30g to the nose for a sub-250g would make me look at redesign, and redistribute weight and size of components to reduce/eliminate that necessity. Thanks for the video. Great project.

Your video is just fabulous, shoot & video editing also very appreciative. Keep making such content

it looks so cool

I have had a lot of success using much thicker airfoils towards the wingtips. Like MH64. and using up to 5 degrees of washout. Depending on the thickness of the tip airfoil you can get away even with no winglets.

Thanks for that!

Now this is something you don't see everyday

You should have designed in some dihedral, 4 to 8 degrees would be good for that model and about 4 degrees washout at the wing tips.

The servos should have been mounted more in front to save you a lot of lead added in the nose. Tip: save some grams with a lighter motor, move servos forward, drill holes in elevons to save some extra grams. One gram saved in the rear saves you a couple of grams in the front.

I can recommend you buy some epp foam wing like s670 or diatone reaper. And you will have more fun than a headache, and also it's cheaper than balsa)))

Loved this video!

Just a suggestion for tip stall and to increase the longitidunal stability, you can use reflexed airfoil if you do not, because they are very beneficial when the aircraft tends to nose down. And also, you can use some washout on the airfoils near the root chord, it will provide you to get rid of this tip stall ✌🏻

Good tip!

Thank you this is very helpful. Im doing the same thing right meow. Minus the computer and laser cus broke lol this video has helped in design tips!

The problem is the tapered wing. The wingtip airfoil dies the reynoldsnumber-death. Try a design without any taper. Do not go below 15 cm airfoil-length. And a wingspan of 90 cm. Take a sweapback of 20 degree per side. This will work graet.

Regards Tom...

Have a look at the work of Al Bowers on the Prandtl wing. About 8 degrees (angle of attac)k of washout at the wing tips compared to the centre of the wing's angle of attack.

Noice build, cheers

It looks like a wing stall, not a tip stall, like the F100 supersabre when it was taking off. The simplest solution is using aerodynamics elements on the upper part of the wing in order to redirect the windflow and not letting it stall your wingtip, something like the Mig-19 wing, check it out and let us know.

P.S. I would add them right where the middle fuselage part connects to the wings and if it doesn't help, another pair (smaller maybe) abaout in the middle of each wing, good luck!

Very nice project. Looks amazing. Think the low-speed stability issue is a characteristic of flying wings, and the lightweight of this airframe. Large scale flying wings use drag rudders, or split controls to offer better yaw control. Something more complex and added weight a model this size doesn't need.

Curious what model you will build next from design, or modified design. Having laser cutter is a dream tool. Perhaps you can even cut foam board too? So many possibilities. If only had infinite amount of free time.

Thanks! the laser cutter unfortunately does not cut white foamboard easily, I think it needs to be a infrared laser.

I'm late here but a wider tip will help with the stall, spins.

Cutting = 20 min. wow! Plus, those burnt edges are stronger than raw wood edges.

ممنون از ویدیو

A am also flying wings fan and I would suggest FrSky S6R or S8R receiver with built-in flight stabilizer.

PW51 airfoil could be good. Is used for nano goblin plane. A fuse with a rudder would help, otherwise, have a look into the prandtl wing design from NASA if you want a wing with no rudders or vertical surfaces.

Great Build beautiful job If you design this again move your servos forward try to get them closer to CG mark might help with balance and a vertical fins closer to the Pod would help for stall

take care

Thanks for your opinion!

Check Prandtl wings. Check adverse yaw.

Yet in nature you don’t see a wing flying alone, there’s always something like a fuselage to stabilize the pitch. That’s why an alone standing or in this case an alone flying wing has a lot of maneuverability limitations compared to common elevator rudder aileron design, although birdlike flight is the benchmark, glide ratio and energy management amongst other features included. One big hurdle then in the way of achieving birdlike flight capability is getting rid of the vertical stabilizer and mounting the elevator on a pivoting mechanism like they do in birds.

Apparently the sweep of the wing really make difference. I used to fly wing like yours, not so much backward sweep like S800 EPP WING and it suffers same problem, tip stalls and couldn't recover, also need so much weight at the front. Try more backwards angle like FPVWRA Specwing and I never encounter tip stalls again even gliding and turning for long time.

Your videos are fantastic. It's great seeing such an engineering mind, at work. A job well done. I've subscribed. Thank you!

Nice video bro

I used to have a CO2 laser and laser-cut balsa parts for a model I was designing.

I used mostly 3/32" and 1/16" balsa .... perhaps you can go to thinner material?

Also, perhaps your solid-state laser can benefit from an air-assist add-on, maybe cut the balsa in one pass?

Very nice build, and congratulations, you just discovered the reason that the original YB-49 flying wing crashed and killed its Pilot, Major Daniel Forbes, and Co-pilot, Captain Glenn Edwards, in June 1948. It is also the reason that the Flying Wing program was scrubbed. The Flying wing is one of the most efficient designs ever, but it is also inherently unstable at low speeds. It is susceptible to spinning at low speeds. But when Fly by wire control systems and sensors were developed. The government reactivated the program and developed the B2- Stealth bomber.

Great piece of history there, I've heard of it, and yes, it takes a bit more research and work to make it more stable.

Kevin Maloney, I was thinking the same thing. I understand that there is a lot of real time processing that goes on to keep the B2 flying stable.

I have a mini speedwing made from epp foam that is about same size, flies great. Kit no longer made. Not flat bottom foil. Been flying it over 15 years. I used li-ion battery got 30 minute flights.

reduce the control throws or add exop. this will help

Nice video ,thanks man

8:05 atleast here in the Netherlands (i don't know about other european country's), those rules are for drones. First I thought rc planes qualified as a drone aswell, but for some reason they have different rules for model airplanes. They are much less strict: no age restriction, flying without license till 20kg or something, and the regular no-fly zones.

Hi loved the video demo of the laser cutter you bought what is the make of it and where did you get it from.

Thanks.

Delta wings are notoriously difficult to setup. My son built a flight test wing from foam board plans. We had to jostle with the CofG until we found the sweet spot. It had big wing fences on the tips. I like the idea of putting a mid wing fence as someone else has already suggested. Take a good look at a Microlight’s flex wing setup. They have a fair bit of up flex in the centre of the wing. I used to fly them and they are super stable wings. So maybe add two trim tab’s either side of the engine in the centre of the wing with a fair bit of up until you find the best position.

Lovely build. Looking forward to green software tools video. What is the cost of the laser cutter BTW?

Thanks for your ideas, the laser cutter price is about the same of a 3D printer, $300 - $400

actually, delta's are usually very easy to design and tune. This is not a delta.

I have been building flying for a long time now.. and with all that experience I can say is.. choose a better airfoil.. with a bit more thickness.. and add some more sweep.. I have used the same airfoil aswell.. but never really got what I wanted.. because that particular airfoil needs a lot of speed for stable flight.. I ended up using some other airfoil..

Stability is improved by using a different airfoil cross section in the middle of the wing, as opposed to the wing tips. The middle section should have an airfoil with a relatively sharp leading edge. In a model of this size, the radius of the leading edge might be 2mm. At the wing tips, the outer 25% of total wingspan, the radius of the leading edge should be greater, perhaps 5mm. It will be necessary to design and construct transitional airfoil shapes to make the transition from center section to wingtip section. The result should be an airplane that will begin to stall in the middle of the wing, and this will allow the airplane to be controlled during an incipient stall event. Since the wing is not twisted, the efficiency of the airplane is preserved. In a full scale airplane, this would result in greater range, for a given amount of fuel burned. In a model airplane, the battery power supply to the motor will last longer.

Ok, for a bit I was totally fascinated by the Horton Ho-229, and I vaguely recall something about stall behaviour and CG. I'm sure I don't recall the details entirely, but flying wings definitely don't have very good stall characteristics with aft CG, so either you keep them moving fast or you get the CG very far forward. This was a huge problem in the Ho-229 because it either meant you added weight and thus had less range and/or less payload, or you had to maintain a higher speed to stay well clear of a stall. I vaguely recall that they lost one pilot in a botched landing, and a second swore he'd never get into the plane again.... and this plane was not the first flying wing the Horton brothers had built, although I think it was the first powered plane, and certainly their first jet.

Do you have washout in the wings? That could help the tip stalls.

Awesome build! I like the color scheme, but I recommend putting a bright opaque stripe on the bottom of one of the wing panels for better orientation. It's easy to lose orientation with transparent covering. As for tip stalling, try using some reflex in the control surfaces.

Btw, I was told that Lightburn can convert PDF plans into the proper format. Have you tried it? I just got my first laser engraver / cutter and I have a large collection of PDF plans that I want to use.

Ballast weight in an aircraft is the ultimate sin, you should look more into how to calculate a CG from the get go.