Why do we put reducers in the ductwork trunkline.

HTML-код

- Опубликовано: 6 фев 2025

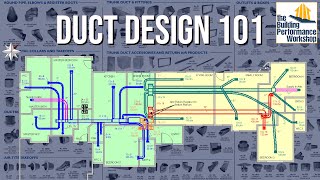

- This one covers how to keep the trunkline FPM the same throughout the trunk. This video is part of the heating and cooling series of training videos made to accompany my websites: www.graycoolingman.com and www.grayfurnaceman.com to pass on what I have learned in many years of service and repair. If you have suggestions or comments they are welcome.

If you are a homeowner looking to repair your own appliance, understand that the voltages can be lethal, the fuels are highly flammable and high pressures are used. Know your limits.

Trunkline - a detonating cord line used to

connect the downlines of other detonating cord

lines in a blast pattern and usually runs along

each row of blast holes.

Question: I currently have an 8” supply in the center of my kitchen. But I’m wondering if I could T that off into two separate supplies so I can have one on each side of the room instead of one in the middle. It’s a 15’ long room

Great video, May I check, the purpose of reducing the duct size is to get the same air volume, CFM output?

Its primary purpose is to keep the velocity up, which keeps up volume at the diffuser.

GFM

@@grayfurnaceman thank you so much!

Great video. Can't wait for the next one. Thanks for sharing.

Thank you!

great video

what will be the size of the second duct which reduced?

At what point after the last branch should the reduction start... i.e... 6in's, 1ft, 2ft?

Can you have a trunk that has two elbows in it, or is that a poor idea? In order for my trunk to run the entire length of the house, I need it to bend upwards and then the second bend puts it horizontally again, so it actually would be located on two floors. Would this work? Thanks

It is commonly done. The ductwork sizing must be adjusted to compensate for the added friction.

GFM

Is there any way to know how many fpm each register removes so I can calculate where to put the reducers?

I can give you a nominal CFM of about 100. Of course this depends on static pressure.

GFM

@@grayfurnaceman I'm not sure what you mean. I know that a 8" register will subtract about 200 cfm, a 10" about 400cfm, but I don't know how many FPM they subtract so I don't know where to put my reducers in my trunk to keep the FPM up where I want it.

Air velocity in the trunkline does not directly affect the outlet flow; only the pressure determines the flowrate through the outlets assuming they have identical geometry. A smaller trunkline will result in a higher pressure drop and a lower flow through the furthest outlets. I'm pretty sure the trunkline reduces in size mainly to save on materials. If velocity is being held constant, it is probably because it will yield a similar pressure loss due to friction over a fixed distance.

how i will find out thanks watching you for years I've donated before

You could check with city hall.

GFM

Hi, do we reduce it after 10 feet from air handler ?

I reduce when the number of take offs drops the FPM below about 600.

GFM

@@grayfurnaceman and FPM = velocities right ?

@@yamazaheer6966 Yes, feet per minute.

GFM

@@grayfurnaceman thank you sir. If you could make a video on how much cfm is needed per room in a near future. I know that the rule of thumb is one cfm per one square inch but what if the celling are higher ? Thanks.

Makes sence! Thanks

Welcome

GFM

I am a bit rusty on this. Can you explain the effect of the reducer on the static pressure in the duct? I sort of remember measuring both a flow pressure and a static pressure back in the day when I studied HVAC.

If I am flowing air thru ductwork, with each outlet, the static pressure will decrease. The flow pressure will also decrease because the FPM decreases. If I reduce the size of the duct, I can keep the flow pressure up because smaller duct with the same amount of air moving out of outlets, equals about the same flow pressure. Hope this helps.

GFM

@@grayfurnaceman - With due respect.... not correct. Bernoulli's law states that along a streamline and **neglecting frictional loss**, Pt (total pressure) is constant. Pt = Pstatic (static pressure) + Pvel (velocity pressure). Therefore, if you have a trunk with constant cross-sectional area and branches that bleed off some of the flow (the streamlines go with the branch flow), downstream of the branch Pvel decreases and Pstatic increases by same amount that Pvel decreases. Velocity pressure and static pressure can't both decrease; if they did, you would have a violation of the law of conservation of energy. The downstream branches see higher static pressure and thus will flow *more*.

Remember how carburetors work? When you step on the gas pedal, the throttle butterfly opens. Airflow through the carburetor venturi (throat) increases. Thus, Pvel increases... and Pstatic in the airflow *decreases*. The gasoline is in the float bowl, which is vented and sees atmospheric pressure, right? So when the static pressure in the airstream decreases, there is more pressure difference between the atmospheric pressure that the gas in the float bowl sees and the static pressure in the airstream flowing in the carburetor's venturi. So more gasoline is pushed into the airstream... which is just what you want.

Frictional loss is a different thing entirely. As air flows, there is friction in the in the flow that creates a loss of Pt (total pressure). Frictional loss increases along the length of flow. There are many things that play into frictional loss, but in simple flows such as airflow in an HVAC duct, it's roughly proportional to slightly less than the square of the flow velocity. In other words, for the same duct at the same temperature, if flow is twice ( 2 times) as high, the frictional loss in the duct will increase by just a tad less than 4 times as high; if flow is three times higher, the frictional loss will be a tad less than 9 times as high. If you keep trunk velocity high, the trunk frictional loss will also be high, and you could have trouble balancing your branch flows while keeping the total external static pressure across the furnace or air handler blower to less than 0.5" w.c..

.

@@bahhumbucker Bernoulli's law does not apply here. You are decreasing the duct size in response outlets that reduce air volume in the duct. There is also virtually no venturi effect at the low

I’m sure you understand what you’re trying to say, but these paragraphs are atrocious. I have no idea what it is you are trying to say or prove, because your writing is bordering on techno babble because of how incomprehensible the sentences are. I’m not even trying to be mean or anything, I’m just being honest here; but I have a feeling you’re gonna take offense

Gary would I have to insulate spiral ductwork in a building with a metal ceiling

If the ductwork is in the conditioned space, it is not required but may be helpful.

GFM

it is an auditorium with no drop ceilings just hang spiral both for heat and cool 25 ton AC 360000 BTU gas 3 phase system I am getting discrepancies for it is a commercial building any help would be necessary appreciated

You know, that's probably a local code issue.

GFM

In your first example how could CFM stay the same while FPM goes down? CFM is FPM * DUCT AREA. In your initial example

If it doesn’t exist this is his theory and it makes perfect sense.

Hi... I just replaced my furnace and was wondering what cfm a 5ton drive puts out and what every round 6" take off''' takes away cfm wise, thanks...

thanks for this Info, and wondering what 8" x 16" duct can Handel cfm wise..

Urgearhead I will be doing some videos on using the ductilator to calculate sizes and air flow as soon as I get time.

GFM

look forward to it, thanks... Im a Building engineer in down town Chicago..good to learn basic HVAC.. thanks..

About 400 cfm per ton

How to do ducting all things

If two trains with ducts are traveling from California to Boston....

What you call flow pressure is irrelevant in residential duct design. Supply static pressure is going to be lower, the further away from the blower, no matter what. using a reducer is only going to reduce static pressure even more. You are not regaining static with a reducer. I think you are conflating supply register velocity with trunk duct velocity. Register velocity is a function of the register and cfm.

Well, I guess we will just disagree.

GFM

@@grayfurnaceman You are disagreeing with ACCA manual D. It contradicts what you are saying completely.

@@Marty1911 You will have to direct me to the article. As for "flow pressure" you will have to direct me to where that too.

GFM

@@grayfurnaceman It's called ACCA manual D. Obviously something that you are unfamiliar with. As for "flow Pressure" that was a term that you used in a reply in this thread. A clue to that would be my comment "what you call. " You really should educated yourself before you try to teach others.

@@Marty1911 Well, I did teach the manual D for 9 years. I am asking you for where you found the information you are referring to.

GFM