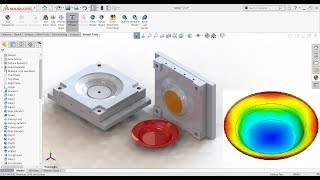

Getting Started with SOLIDWORKS Mold Tools

HTML-код

- Опубликовано: 11 дек 2024

- Hosted on 5/14 by Greg Buter

Join CATI for a quick introduction into the mold tool design features found in all versions of SOLIDWORKS. Focusing on plastic injection molded product tooling.

It's critical that your plastic parts can be manufactured. Injection molding is one of the most common methods. This manufacturing process often requires complex mold tooling to be designed and machined. Your part design will need to meet critical geometry requirements in order to be moldable.

Holes in your part will require shut-off surfaces. Undercut geometry will require side cores and lifters. Core pins can help preserve tooling. Tooling interlock can maintain alignment and ensure part consistency. "

Subscribe to our channel: on.cati.com/yo...

Visit our website: www.cati.com

Follow us!

Facebook: on.cati.com/fa...

Twitter: on.cati.com/tw...

LinkedIn: on.cati.com/li...

Instagram: / computeraidedtechnology

thank you Greg Buter

Overall a great tutorial explaining the mold design process.Thanks.

Thank you for the great video. A link to the file on grabcad or somewhere else would be a huge help for people trying to repeat the steps.

in the dust pan example during the parting surface step if you are still getting a minimum curvature radius indicator after going to smoothing how would you proceed? I would think to just manually edit that surface but would love to know your suggestion thanks!

Really great video! Thanks ;)

Sir I have one 3d part model so can you do core and cavity extraction?

great!

Best

horrendous, why make a vid/tut but explaining nothing...why this draft angelt etc pp, when to use what

This is way too fucking hard