Flow Control Options for Industrial Fans

HTML-код

- Опубликовано: 9 сен 2024

- Visit airprofan.com/ - Call 715-365-3267 - Email fans@airprofan.com

Don’t want to go with the flow? There are five primary ways to control the volume of airflow through an industrial fan. Methods include various damper and drive solutions. Sales Manager Chet White details the choices and their effects on the fan curve in this 16-minute video.

Full Transcript:

We’re going to talk about flow control and the various methods you can use to control the flow in your fan. There are 5 that we’re going to discuss. The first is an outlet damper. The second is an inlet box damper. The third is a variable inlet vane damper. The fourth is a variable frequency drive. And the fifth thing is combining the variable inlet vane damper with a variable frequency drive.

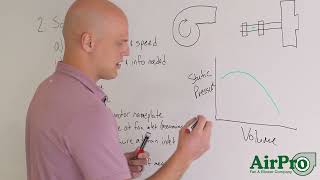

Our first method, and the most common, is the outlet damper, which sits right on the outlet of your fan. You control flow typically with an opposed blade-style outlet damper. Over here on the righty we have a typical fan curve with the volume on the x-axis and pressure on the y-axis. We’re going to show you what happens when you use an outlet damper to affect your position on this curve. If you’re getting more volume than you need for the static pressure on your curve? Using an outlet damper, you’re able to close those blades to move back on the volume scale and up on the pressure scale as far as the fan is concerned, cutting down on the amp draw from the motor. If you close the damper too much, you can hit the surge zone, which you want to avoid.

Now we’ll look at the inlet box damper, which goes on the inlet of your fan and turns the air into the fan. This is a parallel blade design to start the prespin of the air to get it moving in the same direction as the blades are turning in the blades of the fan. On the curve, an inlet box damper has the effect of moving the curve. So as you close it, you’ll slide back on the volume scale and down on the pressure scale. This also can hit the surge danger zone, so you’ll need to be careful not to close it too much.

The third method is a variable inlet vane damper, which is far and away the best method. It mounts to the inlet of the fan, with a bullet nose design off of which all of the vanes are mounted. They go all the way around the inlet vane damper, and they shut in the direction of the air inside the fan to prespin the flow to help the wheel that’s operating inside the fan. On the fan curve, the variable inlet vane damper has the effect of moving the volume back to the left while maintaining the same amount of pressure. This is superior to the other damper methods because it allows you to maintain performance without encountering the surge danger zone.

The fourth method isn’t a damper. It’s a variable frequency drive on the motor to modulate the speed up or down while the fan is operating. What does that do to the curve? The system has a system resistance curve that looks like a normal parabola. The variable frequency drive rides the system resistance curve, physically changing the fan’s static pressure curve down or up depending on the frequency in hertz of operation. This is by far the most efficient method of controlling flow because you’re not introducing anything into the stream as a pressure source, and gaining energy savings.

The highest possible control while trying to avoid the surge position is to combine the VFD with the inlet vane damper. This provides the efficiency of the VFD in riding the system resistance curve while allowing you to go up on speed without increasing flow. If you just have a VFD, both pressure and volume will go up or down together. On the curve, the effect is to change the system resistance curve to meet the changed pressure curve for the fullest method of flow control.

VISIT OUR WEBSITE:

airprofan.com/

SUBSCRIBE TO OUR CHANNEL FOR OTHER VIDEO TIPS & HELPFUL INFO:

/ @airprofan

SUBSCRIBE TO OUR EMAIL LIST:

airprofan.com/...

LET’S CONNECT!

Email: fans@airprofan.com

LinkedIn: / airpro-fan-and-blower

#IndustrialFans #CentrifugalBlowers #Manufacturing