Directional Control Valve Centers

HTML-код

- Опубликовано: 16 сен 2016

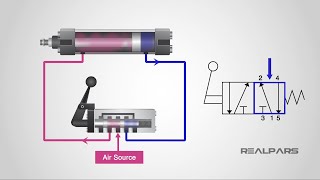

- When analyzing a system schematic, it's worth thinking about how the directional control valve centers were chosen. It depends on whether a fixed or variable displacement pump is used, whether there is more than one parallel subcircuit, and a few additional factors. The Live Schematic shown in this video lets us reconfigure the system with our choice of valve center, pump, and more. Watch how we find the most effective design.

We make all the interactive animations ourselves, and they're available online at www.lunchboxsessions.com

Follow us for more great videos and learning content on your preferred social network:

LinkedIn: / cd-industrial-group-inc-

Facebook: / lunchboxsessions

Google+: google.com/+lunchboxsessions

Twitter: / lunchboxsession  Наука

Наука

This is by far the best Hydraulic principle I have ever seen in my life. Thanks for this free knowledge man

Beautiful problem to understand each of the centers. Thanks a lot !

a very good demonstration and I understood very well, thank you very much.

Pierrot de Quebec Canada

Very clever the solution of series connection instead of parallel.

thank you very much it's very useful

sir, all the explanation provided here are very sound and clear..please provide an animation for manifold fabrication method

awesome sir 100%concept your voice is pretty good like ncc or bbc news anchor.

Fantastic video and solution.

Excelente! aula muito obrigado.

Thank you very much

Great video!

Thank you for very much

Greatful. Thank you

Super explanation

Muito obrigado carnal agora sem entendo... e una delissia!

Very useful

thanks for the amazing explanation, it is so helpful! can you please mention the name of this tool that you are using ? @LunchBox Sessions ??

Have learned n enjoyed

Thanking it is great

In parallel connection with 2 tendom center valves, is it able to operate two pistons at a time?

you have to be careful putting full pressure on the tank side of the valve. most valves cannot resist that pressure. When using a fixed displacement pump (typical gear or vane) you need a "power beyond" port on the valve. That allows for safe pressures in the return/tank side of the valve and doesn't risk blowing out a low pressure seal/actuator. most valves can be purchased with this option.

Very good explanation

I am wondering which centre type is more suitable for a mini skid steer motor circuit application. I used close centre one and found some what jerk at the beginning of Valve?.

Great!

What kind of internal leakage do you get in spool type valves?

I would love to know what software you are using. I'm a school teacher and would love this to illustrate it to my students

Can you share link from which I can get this software/Excel

Excellent demonstration and I understood very well, thank you very much.

I would love to know what software you are using.

Right now, using Photoshop software which is difficult to make animation.

I'm a school teacher and would love this to illustrate it to my Marine engineering students.

thanking you in advance.

Wow! You just answered my question about using a closed center DCV for a bi-directional winch motor. I am going to a Variable Displacement Pressure Compensated pump from a Fixed displacement gear driven pump with a tandem center DCV for the winch motor which worked very well for that system. People tell me a float DCV is better for my new system but I can’t see it holding a load as needed in the center position?

Also I see you have a sensing line after the pump back to the compensator. Question is if the second actuator was a single direction motor i.e. compressor motor could I T my pressure sensor line in the pressure line of the compressor motor and run both DCV and compressor pump without any mixup in compensating signal from the sensor closest to the pump?

How does the 3 position DCV stop on the centre position? Let's say one side it is spring activated and the other side by solenoid

But when in series will you still be able to operate both cylinders?

The only problem I trying to find out is how work 2 or more hydraulic cylinders with a open flow system at the same time.

Which softwares can be use for this

Two cylinder working in same time which one best diagram Sir

I enjoy viewing video trying to register for more lesson. Not yet open to public, when will this change

We are hard at work finishing up the public parts of the website, and will launch as soon as they are ready. If you register now (www.lunchboxsessions.com/signup) we will notify you once the public site is open later this year. That's the best way to make sure you get access to our free learning content right when it becomes available. Thanks for your question.

I think you must emphasize the advantages and disadvantages of each type of center position into a highest level for viewers awareness.

Tandem valves are just for simple cheap hydraulic systems. Mostly one actuator with fix displacement pump. Making series circuits using tandem valves are dangerous on higher pressure. Tandem valve is also the weakest among 3 position spools. Close center are used with multiple actuators but they are not as desirable and creates more problems on complex systems.

I think you have to give more emphasis on the float type because it's (and its variations) the most commonly used fieldwise.

Old machines used lots of fix displacement pumps from medium to higher pressures but newer ones imo use more variable displacement ones thereby limiting the use of 4/3 closed centered.

In mobile applications you could hardly see any closed center valves. I'm worried that some dumb aerospace designers may have used valves of these types(closed cent).

More emphasis on float type (and some variation)as they are most commonly used by good designers.

Thanks for your valued input. Without a doubt we'll do more videos that showcase one valve position as opposed to another. We've encountered all four of these valve centers on both mobile and plant based machinery. The objective of the video is more to help a schematic reader as opposed to a system designer.

Have you seen Directional Control Valves Basics Pt. I ruclips.net/video/CQPwvWXbV3w/видео.html and also Part II ruclips.net/video/o-A_9nFpzek/видео.html

Also you might enjoy Pilot Operated Check Valve Cylinder Troubleshooting - Part 1, 2 and 3 starting with ruclips.net/video/tyRTbdAuMxI/видео.html On that video we're into that float center that you mentioned, in a big way.

Thanks again for writing. -Carl

Please explain their advantages and disadvanges in terms of construction equipment.

As I understand, a main thing that makes parralel configuration more preferable is operation of both cylinders in the same time. Is it all?

L9bus when you use counterbalance valve, brake valve, pilot operated check valves etc you need to have input/output(A/B) lines vented at these valves basic positions. Various shuttle valves are also installed for so many purposes that needs to be vented including load sensing and/or venting Relief valves as well as destroking the variable displacement pumps.

will both cylinders operate simultaneously in the series configuration ??

If ones tries to operate both cylinders at the same time, when in the series configuration, the load on the downstream cylinder back pressures (resists) against the flow leaving the upstream cylinder. This makes the upstream cylinder weaker in terms of the amount of lifting load, which could now trip the system pressure regulator (relief valve, or pump pressure compensator) as loads in series sum together in terms of system pressure. The other issue comes from a cut-off of flow available to second cylinder if the first cylinder (perhaps shorter, or started extending earlier) reaches end of stroke and then is deadheaded. Now there would be no flow to cylinder no. 2. The tandem center (P to T connected) valve, chained together in series is generally meant to be for a system where only one application (directional valve and actuator) is used at any one time.

thanks :)

How are you ref happy day We are ultra precision company BAEK YEON thanks

Good day

The video does not run ???

This sounds like an issue with your internet connection, web browser, or RUclips. You could try a different computer. Good luck!

do you have 6/3 animation

We'll keep your suggestion in mind. Thanks

I assume you could not operate both cylinders at the same time

sir may i know the software name.

Very good and informative, one thing though, could you take that drumroll out? Its just irritating!

D.c valve pilot check valve and presser switch and sensor meni pold diagram meni fold dikhaye.please ..🙏🏻🙏🏻

Vinod Habale TYME

plus video minus minus background noise

Teacher, there's problem your video.

Hi Michael. As far as I can see, the video is working correctly. Can you tell me more about the problem?

It is better!

Thank you for message.