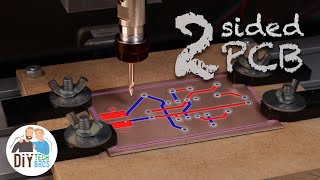

Relay Calculators: Episode 8 - Using FlatCAM and a CNC mill to make PCBs

HTML-код

- Опубликовано: 26 янв 2025

- In this video I go through the process of using FlatCAM to change our Gerber files from DesignSparkPCB into G Code that can be read by the 3-Axis CNC Bridgeport, and then we cut out some new PCBs.

www.rs-online....

flatcam.org/

Music:

ocremix.org/re...

![I.N "HALLUCINATION" | [Stray Kids : SKZ-PLAYER]](http://i.ytimg.com/vi/n5B5q1Hwt_U/mqdefault.jpg)

I've come here from the future... I've been watching you mill boards for ages now... but often wondered about what your process was. :)

Oh my, that is quite a mill. :P

A couple questions for my edification, if you please:

1. I see that you use a V bit rather than a small end mill. Does this produce better results, and if so, why?

2. Does leaving all the swarf on the board during milling cause problems? I see that you have an air nozzle on your machine, but I am looking at converting a cheap 3018 CNC engraver to a PCB mill, so if I need to deal with the swarf, I guess I'll have to make a vacuum boot or something (I don't want to blow all that swarf all over the electronics workshop with an air nozzle, lol).

Thank you, sir. You are a gentleman and a scholar.

Thank you! I love our little Bridgeport EZ Trak!

The primary reason I use a V-bit as opposed to a small end mill is simply size. I use 1mm trace widths with a trace spacing of 2.54mm, which is already much wider than a standard PCB uses. That means there is 1.5mm of space from the edge of one trace to the edge of the adjacent trace. The smallest end mill bit I could easily and cheaply find is 1.5mm, which I actually use for cutting the actual board outline. But, for straight line traces, I could just get away with the 1.5mm bit, there are a few places (particularly with my tube designs), where I only have 1mm or slightly less between components that need to be isolated. The 1.5mm bit would just be too big for those situations. The V-bit on the other hand can actually isolate down to really tight tolerances if you get the Z perfectly zero'd out.

On the first few boards I cut when learning how to do this whole thing, I didn't actually have an air nozzle setup, and I don't remember there being any problems from the swarf. It's mostly dust, but sometimes you get long curly strands of copper. But, even with those, I never notice any problems with cutting! I would say just use a vacuum to clean up every 15 minutes or so while it's running and you'd be totally fine.

@@UsagiElectric Do you use a vacuum table, or can that mill make a heightmap of the board? Thanks, man.

The CNC machine is awsome.

That old Bridgeport constantly amazes me with just how precise it can be!

👍