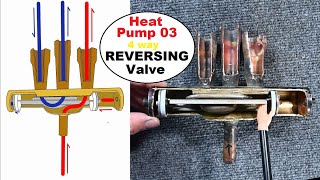

Heat Pump 02 Refrigeration cycle step by step AC-HP

HTML-код

- Опубликовано: 8 фев 2023

- Step by step we convert the refrigeration cycle form an Air Conditioner to a heat pump. Get black red and blue marking device and follow along and you will have the basics down pat!

repetition is learning.

This is a long video done on a what board. this is the same method I use in teaching class.

The most important fundamental of heat pumps.

You are a great human being with a unique understanding of the principles of HVAC. Your efforts are needed in today's sham world of service contracting. Thanks,

Thank you

Thanks so much for such a wonderful presentation.Big up please am your follower on RUclips.

I love your videos for your breakdowns of compressors but this is probably the the most succinct yet thorough explanations of the heat pump reversal I’ve seen to date. Well done and thank you. I’ll be sharing this to a couple people I’ve been trying to explain this to.

Wow! You really have a talent to make the most complex thing into the simplest one. Thank you so much for sharing.....

Ty you’re a remarkable teacher. Thankyou for giving your time

I agree, Ty is an awesome teacher!

Very detailed, love it 🙏

Thanks Dave!

Ty, very well explained. All your videos are excellent. Gifted instructor! May God Bless you.

Thank you!

Wow. I learned so much from this video! I now own a heat pump that can cool and even heat from outdoor air in Minnesota in Winter. I did get a furnace for the very cold days of winter. Duel fuel but always heat pump first. ❤🌎🌍🌏

Excellent Explanation of

Heat conversion!!!

Great video. Thank you so much.

Glad you enjoyed it!

I just became a huge fan. Your way of teaching is so though provoking. Thank you!

Awesome, thank you!

Ty you are the bomb. Still watching your videos after going to NTI. Loving this trade! Thank you for all the material you put out there.

Thank you, that means a lot to me

Its always a pleasure to watch your videos. Great content !! Thank you

Love you Mr.Beast of Hvac

I am it but I do appreciate the compliment

I like the Trane R22 HP on the right side😁.

Amazing interpretation TY every time

Nostalgia!

Thank you, I appreciate that.

Your the best teacher and technician I always watch your videos. Thanks.

I am Maintenance technician and I work hard to become service technician one day.

Thank you!

I was a maintenance tech once too. I am actually doing maintenance on a large building right now.

It's a good way to learn, you get to see how things are supposed to work. Be curious and take a look at things. Check voltage across controls running and not. Look at wiring diagrams and identify components.

So so good 👍 🙌 😍 👏

What I’ve never understood is; a heat pump uses the compressor as the primary source of generating heat, not the outdoor coil. The outdoor unit has to expand and therefore cool the liquid below outdoor ambient so the coil (evaporator) can boil the refrigerant by adding heat from outside air and preventing liquid compression. Everyone says “we use heat from outside to heat inside” but in reality, we sort of don’t. We use that heat energy from the outside air to simply change the state of the refrigerant, enabling it to be compressed. That heat energy gained is minimal, and the majority of the ‘heat energy’ is added by the act of compression. Thoughts anyone?!

Ps… love your videos Ty!!! Big fan from 🇬🇧

It's the heat from outside.

The refrigerant's boiling temperature is lower than the air temperature outside. Because the temperature of the air is warmer than the refrigerants boiling point the heat from the outside air makes the refrigerant boil, changing state from a liquid to a vapor, latent heat.

That laten heat of the refrigerant changing state is very powerful and holds an incredible amount of heat hidden in the phase change. As the refrigerant changes state it absorbs heat from the air so the air leaves cooler.

The best leaves the outside air and inside absorbed into the refrigerant as latent heat hidden heat in the phase change. After all the refrigerant is boiled to a vapor, the vapor is still cooler than the air temperature so the heat from the air will still travel too the cooler refrigerant vapor. This causes the refrigerant vapor to superheat above it's saturation(boiling) temperature. We can measure the superheat but it's overall very little heat but it's important to know we have only vapor going to the compressor.

The compressor pulls in the low temperature, low pressure superheated vapor and compresses it to a high temperature high pressure superheated vapor that will be warmer than the temperature of the air inside.

We can feel the heat of compression but it's only relative to how much heat the refrigerant was able to absorb from changing state, boiling, latent heat, in the outdoor evaporator.

As we absorb less heat from outside we have less heat of compression to work with in the compressor.

@@love2hvac thanks for responding Ty. I must admit I still don’t quite understand as the heat is added via compression. The phase change in the outdoor coil is simply to stop liquid compression; it’s still cold vapour before entering the compressor. I do understand what you’re saying about lower ambients increasing compression ratio though. Maybe explain on a podcast or video some time?! I do feel a lot of people are in the same boat as me and can’t see how cold superheated vapour adds much in the way of heat to indoors. Would really appreciate a video or further explanation. Maybe I’m stupid 😂👍

@tom24057 it's a great question I will see if I can make a video specifically addressing that.

@@love2hvac wow amazing! Thanks Ty, you’re the best! 😃😃

@@love2hvac amazing! Thanks Ty!!

Great info. and demonstration. Thanks Ty.

GREAT! Looks like an older Trane outdoor unit.

Spot on!

@@love2hvac I have 2 Trane XL1400 heatpumps since 2002. I replaced the defrost control board in one unit 3 times! Replaced the ECM fan motor once in same unit. Replaced both caps in both units one time. These older units are real BEASTS!

Outstanding! Thank you

Great info. Thanks for sharing

Sounds great! 😊

Thanks Don!

hi sir can you make video about oil trap if the outdoor/condenser above to the evap/indoor unit. Im new this trade your video help me alot. Thank you sir

I like the way you teach,

1 question, why run different size lines for a system that is reversible ?

The liquid line is still the same subcooled liquid line in either mode.

AC liquid from outside to inside 3/8

HP Liquid from inside to outside 3/8

The large valor line is still a superheated vapor in either mode, cooling mode it's just a low temp low pressure superheated vapor, flowing inside to outside.

Heating mode it's a high temperature high pressure superheated vapor flowing outside to inside.

Hello Ty I hope I’m not asking too much but is it possible when you are done with lessons could you start a journeyman’s prep class?

Prep just for the test?

Have a question. What would cause suction/liquid pressure to rise very slowly. Was working on a Goodman heat pump with a piston at indoor unit in cool mode. When system comes on suction pressure would drop to about 67psi and very slowly rise. Liquid pressure same thing about 219 then slowly rise. Readings finally stabilized

Suction psi 115

Saturation 38.4

Superheat 8.7

Liquid psi 267.3

Saturation 87.9

Subcool 15.9

Indoor temp 70/69

Outdoor temp 69

Temp Split 21

PSC motor med speed

The initial pressure drop is expected with a piston but it seemed to increase very slowly. Just wanting to know why.

It takes about 15 minutes of run time for the system to stabilize.

Any reading before that don't hold the most value

Thank you ty for this excellent learning video...is there an easy way to remember subcooling and superheat because I always get confused how they work...thanks ty...looking forward to the next class 👍

I recommend using the whole word set.

Superheated vapor.

Subcooled liquid.

We breath a superheated vapor, the compressor breaths s superheated vapor.

We drink a Subcooled liquid. The metering device drinks Subcooled liquid.

Saturated means liquid and vapor, think of sea level.

Blue superman flyes above saturation in the low pressure low temp superheated vapor. Super Due to the rescue!

Submarine travels below saturation in a high pressure liquid. The hunt for Red October about a red submarine. We all live in a red submarine, ref for sub cooling, ref for subcooling, High pressure liquid!

@@love2hvac thank you ty...I will study it..

How does the system regulate the temperatures needed to reject heat at the outside coil? Let's say it's 110 degrees outside. The discharge temp and saturation temp needs to be much higher than if it's only 90 degrees outside. Using CTOA for R410A, the sat temp would be 20-25 degrees above ambient temp (sat temp 130). Then it's subcooled by another 10 degrees leaving the liquid line at 120 degrees. When it's 90 degrees outside, saturation temp would be 110 and liquid line 100 degrees. Is this correct? How does the compressor compensate for the difference in temperature required? Is it automatic based on ambient temperature or is it somehow regulated?

If you have a tank of Refrigerant inside at 70⁰F the pressure will correspond. If you take the same tank outside it will heat up to 100⁰F and the pressure will increase accordingly.

Notice the pressure increases when the temperature increases without a compressor.

The compressor is only going to add to that pressure. 110⁰F + 20⁰F = 130F = ____pressure.

If the outdoor temperature is 110⁰F that will be the standing temperature acting against the Refregerant. The compressor (depending on efficiency) will add 20⁰F to that.

It's not that the compressor pumps any harder, it's only adding pressure above what it would be at ambient.

@@love2hvac Thanks for the explanation. So the amp draw should stay the same regardless of ambient temp? The compressor doesn't work any harder when its 110F vs 90F?

The amo draw and the capacity will both change.

As the outdoor temperature goes up, and/or the indoor temperature goes down the compression ratio increases.

As the suction temperature/pressure inside drops there are fewer molecules available to compress.

Meaning it is moving less volume of Refregerant molecules.

As the outdoor temperature goes up there is more pressure the piston has to overcome on the upstroke meaning moree resistance against the motor and more amps to overcome. But the speed of the compressor remains fairly constant.

@@love2hvac thanks for taking time to answer.

How do we control room temperature that is caused by massive amount of heat leaving the high temperature high pressure gas inside the heat pump coil?

A blower moves the air across the indoor coil. The heat is now in the air that is pushed into the duct system that is pushed into the house air. The air should never be blown in people. The air in the home warms up and the thermostat will satisfy ending the 24v call for heat. The contactor electromagnet will realize and a spring will drive the contacts open stoping the operation of the outdoor fan and the compressor ending the refrigeration cycle. The call for fan will also ens at the thermostat and the indoor fan relay electromagnet will energize and a spring will open it's contacts so the indoor fan shuts off.

Now the system is off waiting for the next call for heat.

Oh my god these devices look ancient compared to EU devices :D

And people still complained these are too complicated 😂

Is there an event to where refrigerant can’t saturate above the OA temp?

Yes

#1 Low on charge not enough refrigerant molecules to compress. To raise the pressure and Saturation.

#2Low ambient conditions,

The outdoor temp is too low causing pressure to drop, there is not enough refrigerant available to fill the condensor to generate the needed pressure. This is one reason low ambient kits are important.

I wish the automotive heat pumps could make it that easy with nothing more than a simple three-way reversing valve.

You should see the cluster F$@&K that all the different automotive manufacturers are attacking this thing from different angles, reinventing the wheel, splitting up components in placing them all over the vehicle under the hood.

Automotive industry engineers, first year graduates out of school on math, and may be sprinkled with a little LSD and were told to have a hack at it get it working.

HVAC automotive engineers make the most complicated heat recovery VF our system look like a child’s toy.

A nightmare on steroids. It will be a decade before the automotive industry probably decides on one or two common methods approach of application of heat pumps in electric vehicles and hybrids.. I hope.

People complained about the complexities of HVAC today. They haven't worked on a car or truck recently.

You are correct.

Removing intake to get to the starters, removing fenders or seats to get to the battery. Computer controls under the vehicle.

Makes our HVAC easy!

This is why I keep repairing 1999 but now parts are getting hard to come by. 🤦♂️Can't win!

Tesla is getting ready (considering) to hop into the home HVAC Industry. So glad my active years are behind me. I will enjoy watching the younger generations adapting to the new technologies coming at us at warp speed. My fear is with so few people entering the field & baby boomers retiring at a rapid rate, built-in obsolescence and replacement will be the norm. The big problem is the cost and inflation.

The issue is not the equipment, it's the homes. Its like trying to build a better and better and better bulge pump. But at some point we have to start fixing the leaks in the boat.

Hoses are still being built leaky.

Matt Risinger, Allison Bailes, Joe liberstick and many more are making headway in that area.

Seal tite and ventilate right. It's important for energy efficiency, comfort, human and building health.

I don't deny Elon is a brilliant man but he is spread thin and a lot of his big ideas are not becoming reality even years later. Tesla has a lot of potential like the solar roof panels, the battery wall but they are not solving the problem yet. Nobody knows about his HVAC idea. I would like to hear about it.

@@boby115 1000% agree.

And the very few individuals who were trained and mentored under the old guard that has retired and took out the time and effort and money for further schooling and education, will be the select few who can actually still repair things . And charge the price for it and make a profit.

Compared to the clueless individuals who own businesses who cannot diagnose their self out of a wet paper bag, and cannot even repair a Lego car toy when it is dropped .

The clueless money, grabbing high pressure, sales owners of shops, who only care about the bottom line profit in our completely on capable of even training. Their own technicians is the other problem with this new generation, the last few generations.

@@love2hvac I am attempting to get one of Elon‘s new HVAC modules out of the latest year model tesla. I just missed one last month it was a total out 2000 and $.23 to the salvage yard. The owner of the body shop was gonna let me pinch it out of the vehicle before it got towed off to the wrecking yard but I could not get to it..

It’s really cool looking . The engineers went to great lengths to optimize every square inch in piping and component placement into a very small compact area.

I can’t wait to get my hands on one .